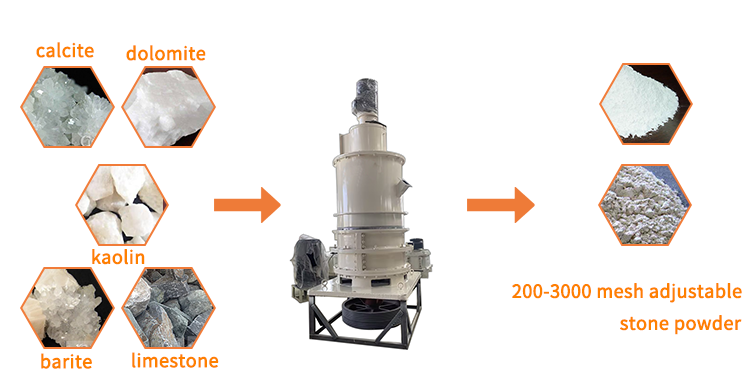

The CRH1000X ring roller mill is specifically engineered for the grinding of brittle materials with a Mohs hardness below 6, including heavy calcium carbonate (e.g., calcite, marble, dolomite), barite, talc, gypsum, petroleum coke, silica, brucite, aluminum hydroxide, precipitated silica, wollastonite, kaolin, bentonite, rare earth minerals, and analogous non-metallic materials.

Production Capacity: 0.6–2.8 tons per hour

Product Fineness: 800–2500 mesh

Key Advantages of the CRH ring roller mill

Safe, Reliable, and Environmentally Compliant Operation

The grinding chamber is free of rolling bearings and threaded fasteners, eliminating common mechanical failure points such as bearing wear and bolt loosening, thereby significantly improving operational reliability. The system integrates a pulse-jet dust collector, acoustic muffler, and sound-insulated enclosure, effectively suppressing dust dispersion and reducing noise levels to meet stringent environmental and occupational safety standards.

Cost-Effective Investment with High Operational Efficiency

Compared to conventional jet milling systems, the CRH1000X achieves superior throughput under equivalent fineness and energy consumption conditions, while requiring a lower initial capital investment and offering a significantly reduced payback period.

Minimal Wear and High Grinding Precision

Critical components subject to wear are manufactured from advanced wear-resistant alloys, ensuring a service life exceeding 12 months under normal operating conditions. The equipment is capable of producing ultrafine powders with a particle size distribution of D97 ≤ 5 μm in a single grinding pass.

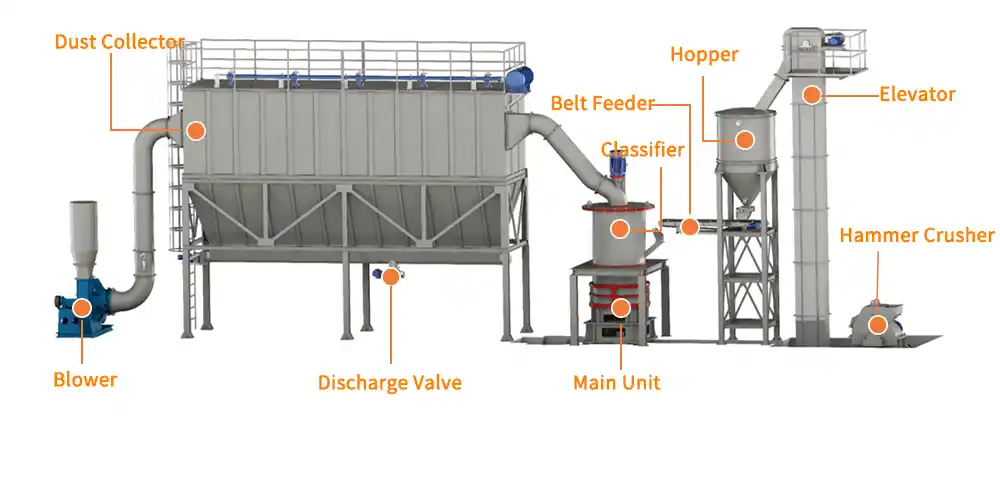

System Configuration for Micronized Powder Production

The integrated grinding system consists of the following components: hammer crusher, bucket elevator, raw material storage silo, electromagnetic vibrating feeder, main grinding unit, dynamic powder classifier, dual-cyclone separator, pulse-jet dust collector, high-pressure induced draft fan, and noise attenuation system.

Operating Principle

The main motor transmits power to the central shaft and multi-tiered turntables through a reducer. The turntables, via pin assemblies, drive multiple ring rollers to rotate and roll within the annular raceways of the grinding rings. Pre-crushed coarse feed material is conveyed by the bucket elevator to the storage silo and then uniformly fed onto the upper turntable by the electromagnetic vibrating feeder. Under centrifugal force, the material spreads radially outward and enters the grinding zone, where it is subjected to compressive, rolling, and shearing forces between the rollers and the grinding ring. After initial size reduction in the first grinding stage, the material progressively cascades into the second and third stages for further refinement.

A high-pressure induced draft fan generates an airflow that draws ambient air into the system, transporting the ground particles to the dynamic classifier. Within the classifier, the rotating impeller creates a controlled vortex that separates oversized particles—returning them to the grinding zone for recirculation—while fine particles are carried by the airstream into the cyclone collector. The finished product is discharged through a bottom discharge valve. The residual airstream, containing minimal particulate matter, passes through the pulse-jet dust collector for final filtration before being exhausted through the fan and muffler, ensuring environmentally responsible and efficient operation.

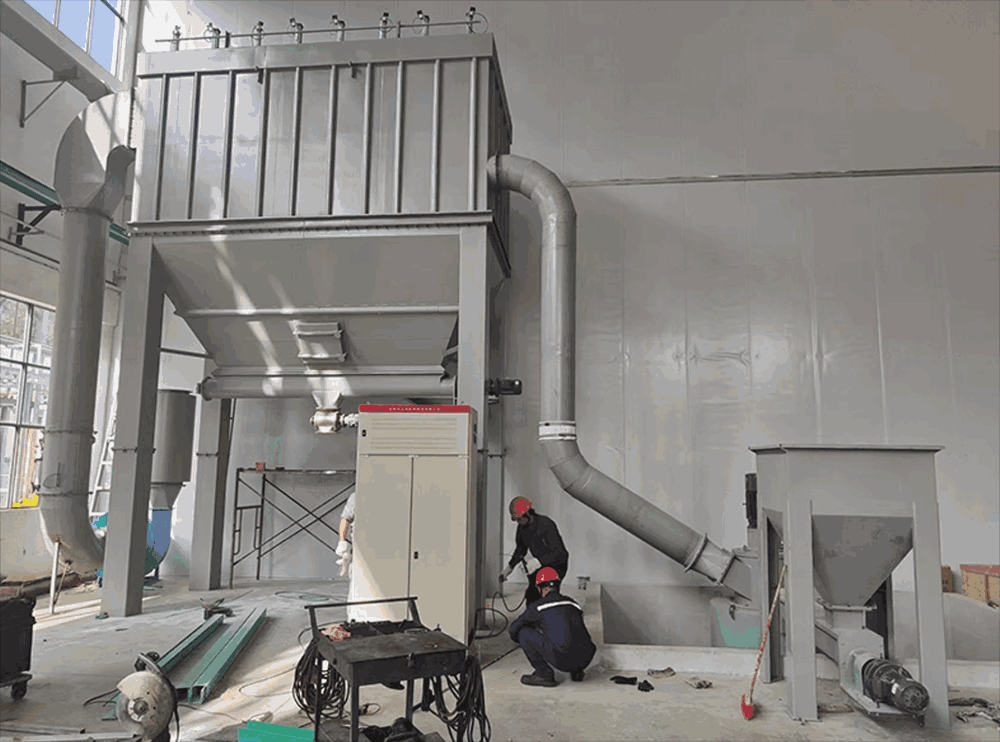

On-site pictures of the ring roller mill

If you are looking for efficient grinding equipment or have questions about the selection and configuration of ring roller mills, Cronus can provide you with professional support. We have an experienced technical and service team that can provide customized solutions based on your material characteristics, production capacity and fineness requirements, ensuring accurate equipment selection and stable operation throughout the process.

If you need further consultation or a quotation, please feel free to contact us at any time. Cronus professionals will serve you promptly!