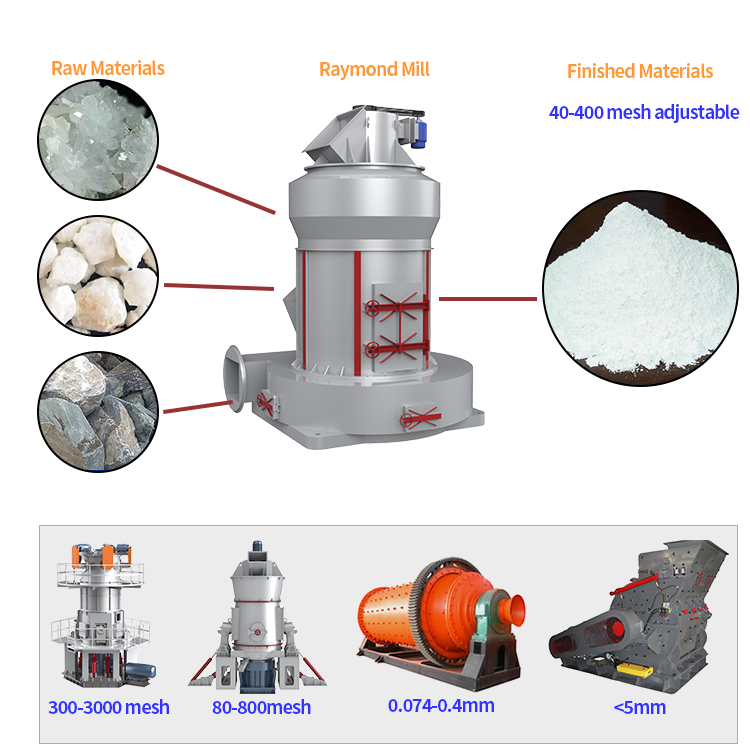

Bentonite is a non-metallic mineral that is widely used in various industries due to its active chemical properties, strong hygroscopicity, and high expansion capacity. However, bentonite must be processed and ground before it can be used. As a country with significant bentonite reserves, my country has continuously strived for innovation in bentonite processing and grinding technology, leading to the development and production of this technology. Below, we will introduce the working principle, technical parameters, and performance advantages of a bentonite Raymond mill.

Bentonite Raymond Mill

I. Working Principle of Bentonite Raymond Mill

Bentonite crushed and screened by the crusher is fed uniformly into the feed inlet of the bentonite Raymond Mill. From there, the bentonite enters the main grinding chamber for grinding. The material is scooped up by a scraper and fed between the grinding rollers and grinding rings. The crushing pressure then blows the powdered material up through the analyzer. Material that meets the required fineness passes through the analyzer, while material that does not meet the requirements returns to the grinding chamber for further grinding. Material that passes through the analyzer is then separated and collected in a cyclone separator.

II. Performance and Advantages of Bentonite Raymond Mil

- The bentonite Raymond Mill features a 1500-2000kg pressurizing device above the plum blossom frame within the main grinding chamber. This increases output by 10-30% at the same power level. The grinding pressure applied by the grinding device increases by 800-1500kgf, resulting in a finished product fineness as fine as 1000 mesh.

- High compressive strength, suitable for a wide range of materials with a Mohs hardness of up to 9.3.

- The grinding roller mechanism of the bentonite Raymond mill utilizes a highly efficient process. The overlapping multi-stage seal ensures excellent sealing. Furthermore, the replacement cycle for the grinding rollers and grinding rings is long, eliminating the short replacement cycle for consumable parts in centrifugal mills.

- The grinding mechanism utilizes an overlapping multi-stage seal, providing excellent sealing performance and dust removal that fully meets national standards.

Through the above information, we believe you have a certain understanding of bentonite Raymond mills. If you would like to learn more about bentonite Raymond mills, please contact us online or by phone. We would be happy to answer your questions.