Contents Catalog

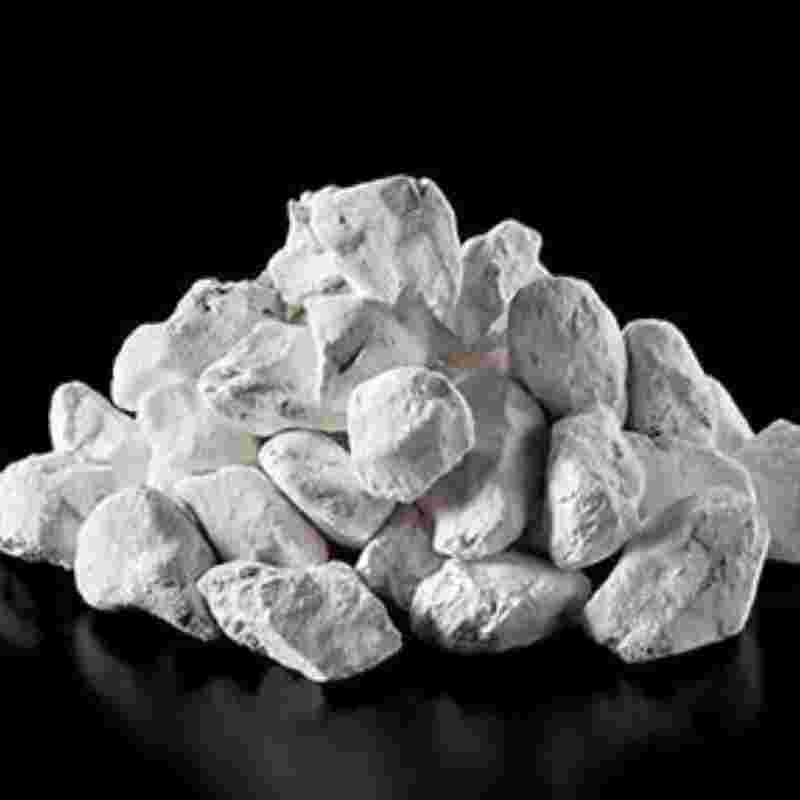

Calcined lime, whose main component is calcium oxide (CaO), is usually made by calcining natural rocks whose main component is calcium carbonate at high temperatures, which can decompose them into carbon dioxide and calcium oxide.

The role of quicklime in steelmaking

| Property | Value / Description |

|---|---|

| Name | Calcined Lime |

| Melting Point | 2572 °C |

| Boiling Point | 2850 °C |

| Solubility in Water | Reacts to form calcium hydroxide (Ca(OH)₂) |

| Density | 3.1 to 3.4 g/cm³ |

| Applications | Desiccant (drying agent) |

| Main Component | Calcium oxide (CaO) |

Removal of harmful elements such as sulfur and phosphorus

In the process of steelmaking, Calcined Lime is mainly used to remove impurities in the charge, especially harmful elements such as sulfur and phosphorus. When smelting iron in a blast furnace, Calcined Lime acts as a flux to react with sulfur and phosphorus to form compounds that dissolve in the slag, reducing the sulfur and phosphorus content in molten steel and improving the quality of steel. The removal of sulfur and phosphorus helps to improve the corrosion resistance and mechanical properties of steel, especially when manufacturing high – strength steel or steel used in corrosive environments, the role of Calcined Lime is particularly important.

Adjust the pH value in the furnace

During the blast furnace smelting process, quicklime, as an important flux, can adjust the pH value in the furnace and ensure the smooth progress of the smelting process. Quicklime reacts with silica, iron ore and other materials in the charge to form slag. The slag not only helps to remove harmful impurities during the steelmaking process, but also absorbs elements such as phosphorus and sulfur in iron, reducing their negative impact on the quality of steel.

Promote melting reaction

During the blast furnace smelting process, Calcined Lime, as an important flux, can adjust the pH value in the furnace and ensure the smooth progress of the smelting process. Calcined Lime reacts with silica, iron ore and other materials in the charge to form slag. The slag not only helps to remove harmful impurities during the steelmaking process, but also absorbs elements such as phosphorus and sulfur in iron, reducing their negative impact on the quality of steel.

Economic benefits of quicklime in steel production

Reducing production costs

As an indispensable raw material in the steelmaking process, the amount of quicklime used directly affects the cost of steel production. By using a reasonable amount of quicklime and controlling its quality, steel companies can optimize the smelting process, reduce the waste caused by excessive use, thereby reducing the consumption of raw materials and reducing production costs.

At the same time, the application of quicklime in steel production can also improve the product qualification rate, reduce the number of defective products or rework caused by the failure to completely remove impurities, and further reduce the operating costs of the company.

Improve the market competitiveness of steel products

Calcined Lime is essential for improving the quality of steel in steel production. Calcined Lime effectively removes harmful elements in steel, improves the quality of steel, and enables steel products to meet higher market requirements.

Using Calcined Lime to improve the performance of steel has become one of the important means for steel producers to enhance their market competitiveness. Especially in areas where special properties of steel are required, such as aerospace and automotive industries, the application of Calcined Lime helps to increase the added value of products.

Promote environmental protection

The use of Calcined Lime can not only improve production efficiency and product quality, but also has a positive effect on environmental protection. Calcined Lime can effectively absorb harmful gases such as sulfur dioxide and carbon dioxide generated during the smelting process, reducing pollution to the atmosphere. The compounds generated by the reaction of Calcined Lime and slag can stabilize the furnace environment and reduce the emission of harmful gases, thereby achieving the goal of environmental protection in the steel production process.

Ball mill processing Calcined Lime

Calcined lime ball mill is an important component of quicklime beneficiation process. Its main function is to select calcined lime raw materials with higher application value and purer properties to meet the high-standard production requirements in various fields.

Working Principle Of Ball Mill

This machine is a skeleton ball mill driven by horizontal cylindrical turning gears, external gears, and two hoppers. The material enters the first hopper through the hollow shaft screw of the feeding equipment. The hopper has a trapezoidal or corrugated sheath, which contains steel balls that fall under the centrifugal force of the cylinder to grind the material. After rough grinding in the first hopper, the material enters the second hopper through a single-layer partition. The second hopper has a flat scale plate with steel balls for grinding the material. The powder is discharged from the grid plate to complete the grinding process.

Contact Us

If you need to process Calcined Lime, please contact Cronus, we will provide you with professional and efficient service! Looking forward to cooperating with you to create value together!