Calcium carbonate is a white solid compound with the chemical formula CaCO₃, commonly found in nature in forms such as limestone, marble, and pearls. It is insoluble in water but reacts with acids to produce carbon dioxide. Calcium carbonate serves a wide range of applications, including use in building materials, industrial fillers, food additives, and pharmaceutical products, making it one of the key industrial raw materials.

The design of the production output is based on specific customer requirements. It is applied as a filler material and is used in the manufacturing of artificial floor tiles, rubber, plastics, paper, coatings, paints, inks, and cables, among other products.

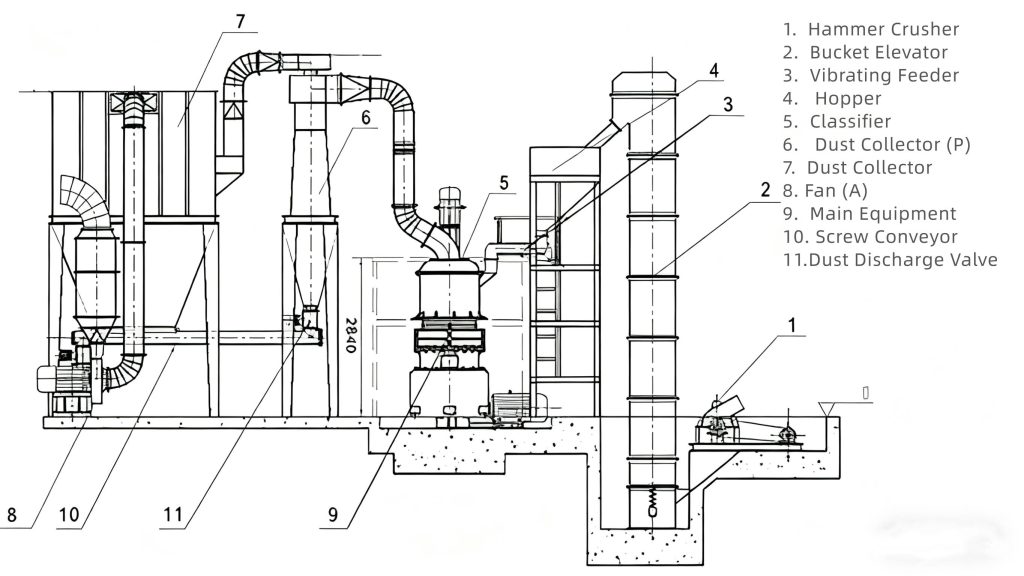

The processing equipment includes hammer crushers, ball mills, trapezoidal mills, and ultrafine powder mills.

The basic process of a calcium carbonate reprocessing plant involves the following steps:

1. Raw materials such as limestone, calcite, and marble are extracted from quarries.

2. These materials are then sorted and cleaned to ensure the high quality of the final calcium carbonate powder.

3. After drying and cleaning, the raw materials undergo primary and secondary crushing using equipment such as jaw crushers and hammer crushers to achieve the desired feed particle size.

Once crushed, the materials proceed to the grinding stage:

4. The crushed materials are fed into a silo and then conveyed to the ball mill via a vibrating feeder. Inside the ball mill, the materials are ground into fine calcium carbonate powder through the impact and grinding action of steel balls.

After grinding:

5. The ground material is transported through a classifier by air flow. The finely ground calcium carbonate powder that meets the required particle size is collected and conveyed to the product silo, while coarser particles are returned to the ball mill for further grinding.

In addition to the core equipment such as mills and classifiers, the system also includes conveying systems, dust removal systems, and packaging systems. The entire calcium carbonate production process can be fully automated and controlled via an operation control panel. The final product is then packaged and stored for distribution or further use.