Contents Catalog

- 1 Vibrating feeder

- 2 High efficiency and low operating cost

- 3 High adaptability and low investment

- 4 Jaw Crusher

- 5 Good stability and high reliability

- 6 Simple structure and convenient maintenance

- 7 Advanced technology and long service life

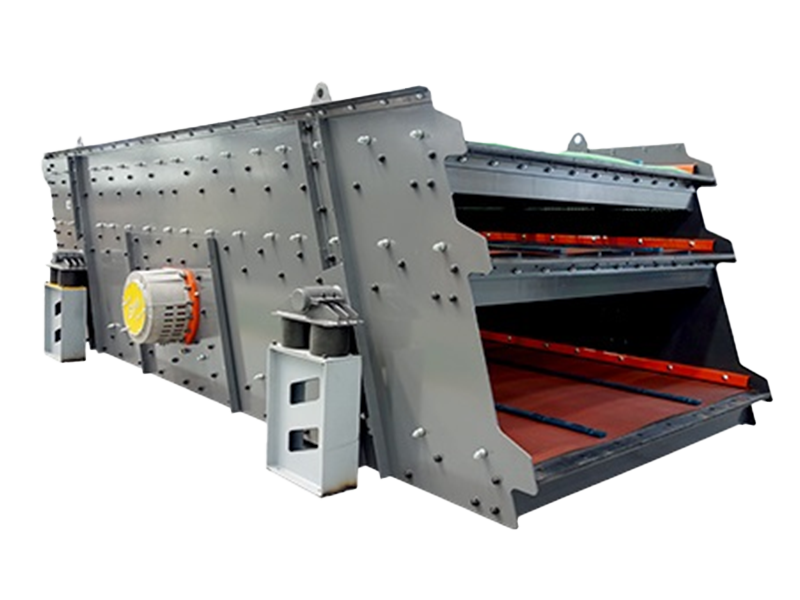

- 8 Vibrating screen

- 9 Advanced technology

- 10 Large processing capacity

- 11 Low power consumption and low noise

- 12 Impact Crusher

- 13 Rotor bearing and plate hammer

- 14 Simple structure and convenient maintenance

- 15 The discharge particle size is adjustable and the particle shape is good

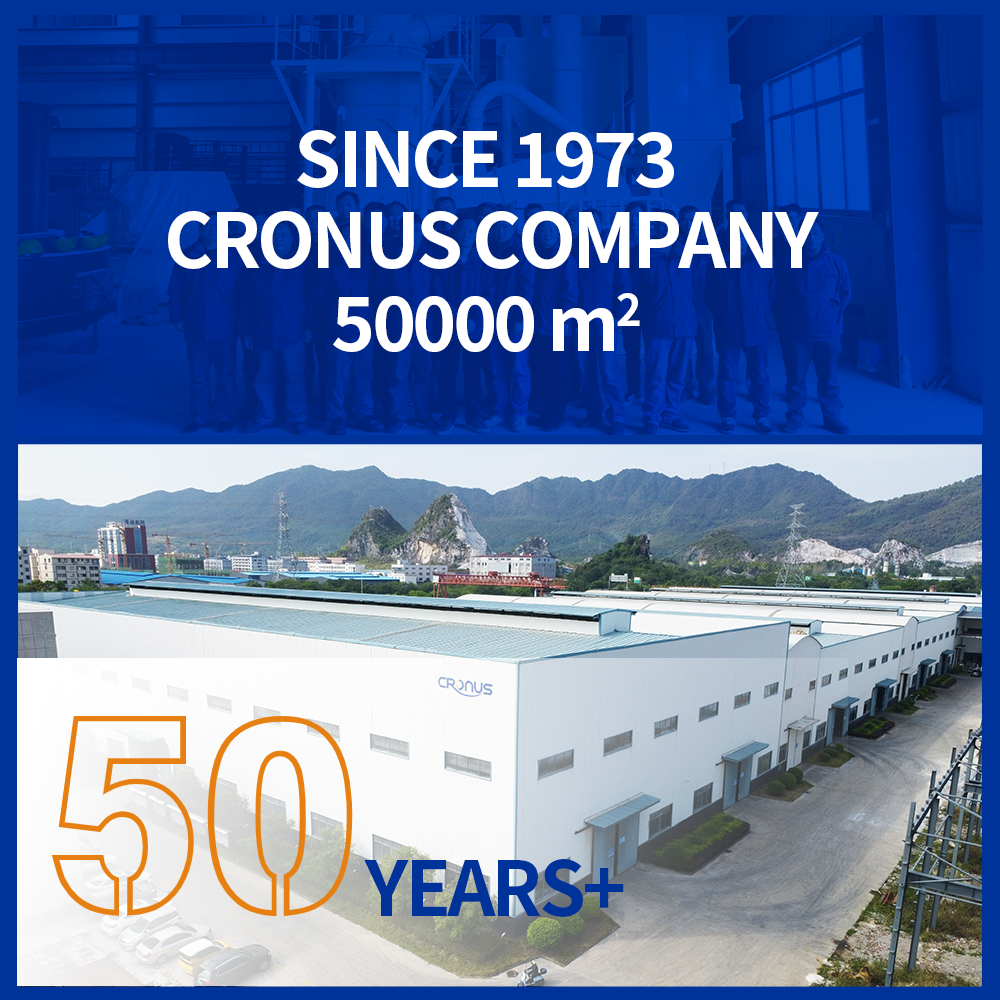

- 16 About Us

Cronus has a rich and diverse product matrix, covering all types of crushers such as jaw crushers, impact crushers, cone crushers, grinding equipment such as European mills and Raymond mills, as well as supporting machinery such as vibrating screens and feeders. These equipments have taken a leading position in the industry with advanced technology and exquisite craftsmanship. Next, let us take a deeper look at the crushing production line.

Vibrating feeder

Vibrating feeder is also called vibrating feeder. In the production process, the vibrating feeder is used to feed block, granular and powder materials from the storage warehouse or funnel to the receiving equipment evenly, continuously or quantitatively. The feeding amount can be adjusted steplessly, and the centralized control and automatic control of the production process can be realized. It can feed materials to belt conveyors, bucket elevators, screening equipment, etc. It can feed materials to crushers, pulverizers, etc., and is used for automatic batching, quantitative packaging, etc., and can be used in the process of automatic control to realize the automation of the production process.

High efficiency and low operating cost

Using double eccentric shafts as the excitation source, the amplitude is stable, ensuring the fluidity of the vibrated ore and rock materials, reducing the channel blockage and material rushing phenomenon, so the ore discharge capacity is large and the efficiency is high; the structure is simple, there are no rotating parts, there are few wearing parts, low power consumption, and significant energy saving

High adaptability and low investment

It has strong adaptability to various ore and rock materials, especially viscous ore and rock materials, and can work in dusty or water-rich environments; small size, light weight, simple and compact, low investment, high cost performance.

| No | Specifications | Value |

|---|---|---|

| 1 | Feed size (mm) | ≤580 |

| 2 | Tank size (mm) | 4900*1100 |

| 3 | Power (kw) | 15 |

| 4 | Processing capacity (t/h) | 180-380 |

| 5 | Overall dimensions (mm) | 4957*2500*1365 |

Jaw Crusher

Jaw crusher is mainly used for medium-sized crushing of various ores and bulk materials. It can crush materials with a compressive strength of no more than 320Mpa. It is divided into coarse crushing and fine crushing. PE series jaw crusher has complete specifications, and its feed size is 125mm~1200mm. It is the preferred equipment for primary crushing. It is widely used in mining, metallurgy, chemical industry, building materials, water conservancy, transportation and other industries.

Good stability and high reliability

The movable jaw assembly is made of high-quality steel castings, and the heavy eccentric shaft is also processed with forging billets, all of which make the jaw crusher have good stability. Compared with other crushers of the same specifications, we use larger and more durable eccentric shaft bearings to give it a higher load-bearing capacity and ensure its reliability.

Simple structure and convenient maintenance

After continuous improvement and optimization, while ensuring the performance of the machine, the machine structure has also been simplified. The entire machine is easier to operate, maintenance is more convenient, and downtime and maintenance time are greatly shortened.

Advanced technology and long service life

For the strength and wear resistance of the heavy eccentric shaft of the jaw crusher, forging billets are used for processing, which greatly enhances its pressure resistance and wear resistance, and greatly extends the service life of the machine.

| No | Specifications | Value |

|---|---|---|

| 1 | Number of screen layers | 3 |

| 2 | Screen hole size (mm) | 3-100 |

| 3 | Screen hole specification (mm) | 2100×6000 |

| 4 | Feeding particle size (mm) | ≤200 |

| 5 | Power (kw) | 30 |

| 6 | Processing capacity (t/h) | 100-720 |

Vibrating screen

Circular vibrating screen is a new type of screening equipment with a circular vibration trajectory. It is specially designed for screening stone in quarries and can also be used for product classification in coal preparation, mineral processing, building materials, electricity and chemical industries. Circular vibrating screen has the characteristics of advanced structure, strong excitation force, low vibration noise, easy maintenance, strong and durable.

Advanced technology

The vibrating screen machine mainly consists of a screen box, a screen mesh, a vibrator, a vibration damping spring device, a chassis, etc. The vibration amplitude is adjusted by a cylindrical eccentric shaft vibrator and an eccentric block. The vibrator is installed on the side plate of the screen box and is driven to rotate by a motor through a V-belt to generate centrifugal inertia force, forcing the screen box to vibrate.

Large processing capacity

The small amplitude, high frequency, and large inclination structure make the machine have high screening efficiency and large processing capacity. The vibrator adopts a large clearance bearing, thin oil lubrication, low noise, and long life. In addition, the components are highly versatile and easy to maintain.

Low power consumption and low noise

The screen beam and the screen box adopt high-strength bolts, with a simple structure and convenient and quick maintenance. The excitation motor is used as the excitation source, with strong excitation force, low power consumption, and low noise.

| No | Specifications | 3YA2160 |

|---|---|---|

| 1 | Number of screen layers | 3 |

| 2 | Screen hole size (mm) | 3-100 |

| 3 | Screen hole specification (mm) | 2100*6000 |

| 4 | Feeding particle size (mm) | ≤200 |

| 5 | Power (kw) | 30 |

| 6 | Processing capacity (t/h) | 100-720 |

Impact Crusher

Impact crusher is a common crushing equipment, which mainly crushes materials by the collision between the high-speed rotating rotor and the impact plate. It is widely used in mining, building materials, roads, railways, water conservancy and other engineering fields.

The equipment has a simple structure and is easy to operate. It can effectively and quickly crush large pieces of materials into the required small particles, meeting the crushing requirements of different engineering projects for materials of various hardness and shapes. With its efficient and reliable crushing performance, the impact crusher provides an important crushing solution for industrial production.

Rotor bearing and plate hammer

The heavy-duty rotor design and strict testing methods ensure high-quality rotors; at the same time, the unique plate hammer fixing device makes the plate hammer more reliable. The bearing seat of this series of impact crushers adopts an integral cast steel structure to ensure the stability of the machine operation; large-size bearings are selected to give it a higher load-bearing capacity.

Simple structure and convenient maintenance

The machine has a simple structure and is mainly composed of a casing, a rotor and an impact plate. Through the lifting device, the frame can be quickly opened to replace and repair the machine’s accessories; the rotor and the main shaft are connected without a key with a locking sleeve, which is convenient for maintenance, economical and reliable.

The discharge particle size is adjustable and the particle shape is good

The top of the machine is equipped with a discharge adjustment device, which can easily and quickly adjust the gap between the impact plate and the plate hammer to control the discharge size; the finished product is in a cubic shape, without tension cracks, and has a good particle shape, which meets the grade standards of various sand and gravel aggregates.

| No | Specifications | Value |

|---|---|---|

| 1 | Rotor diameter*length (mm) | Ф1320×1500 |

| 2 | Feed port size (mm) | 860×1520 |

| 3 | Maximum feed side length (mm) | 350 |

| 4 | Production capacity (t/h) | 160-250 |

| 5 | Motor power (kw) | 200 |

| 6 | Overall dimensions (mm) | 2840×2748×2556 |

About Us