Contents Catalog

- 1 I. Working Principle: The crushing and classification work in coordination to achieve an efficient closed-loop circulation

- 2 Ii. System Composition: Modular intelligent integration ensures stable and efficient operation

- 3 Iii. Adaptability to Materials: Broad-spectrum compatibility features, focusing on the core field of non-metallic minerals

- 4 Technical advantages and key points of operation and maintenance of Cronus Raymond Mill

As a core and mainstream equipment in the field of powder processing, the Raymond mill, with its efficient and stable grinding performance, is widely applied in multiple industrial sectors such as non-metallic minerals, fine chemicals, and high-end building materials. Cronus has been deeply engaged in the research and development and manufacturing of powder processing equipment for many years. Relying on its international technology research and development system, the series of Raymond mill equipment it has developed feature core advantages such as high efficiency and energy conservation, intelligent controllability, and environmental compliance. This article will deeply analyze the technical core and application value of the Cronus Raymond mill from three core dimensions: working principle, system composition, and adaptable materials.

I. Working Principle: The crushing and classification work in coordination to achieve an efficient closed-loop circulation

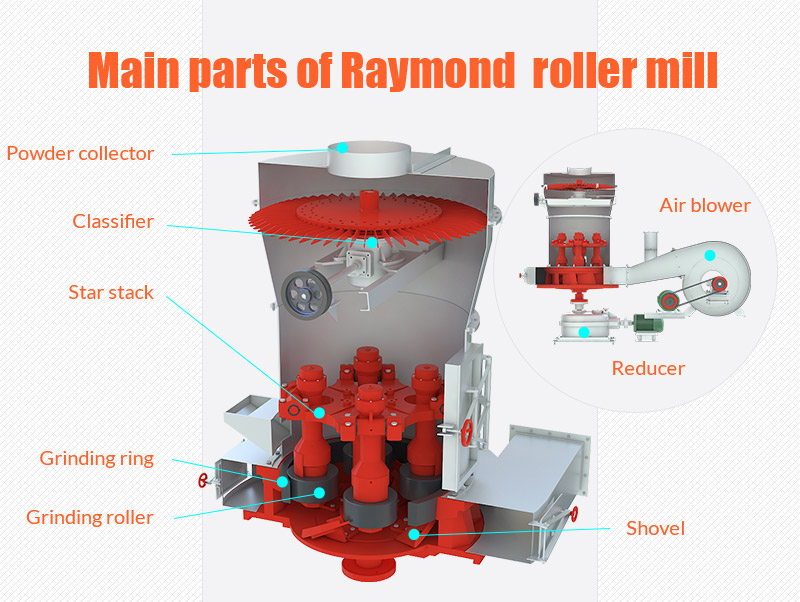

The core working mechanism of Cronus Raymond mill is based on an integrated design of “crushing and crushing + precise classification + closed-loop circulation”. Through the coordinated operation of each unit, it achieves efficient grinding and quality control of materials. The specific process is as follows: Under the precise action of centrifugal force, the grinding roller closely adheres to the grinding ring and rotates at high speed. After being conveyed by the feeding system, the material is evenly sent into the grinding area between the grinding roller and the grinding ring by the scraper. Under the dual action of high-pressure extrusion and rolling shearing, efficient lamination and crushing are achieved. The crushed powder particles are lifted by the directional airflow generated by the blower and precisely sent into the analyzer for classification and screening.

The analyzer is equipped with an intelligent speed regulation system, which can flexibly control the fineness of the finished powder (adjustable from 80 to 400 mesh) by precisely adjusting the impeller speed. Among them, the unqualified coarse powder will be screened and returned to the grinding chamber for re-grinding, while the qualified fine powder will be carried by the airflow into the cyclone separator for efficient collection. The entire airflow system adopts a fully enclosed circulation design. Most working conditions operate under negative pressure, effectively preventing dust from spilling out. The excess gas generated by the system is deeply purified and treated by a dedicated bag filter before being discharged up to standard, truly achieving environmentally friendly and energy-saving production. For materials with a high moisture content, the Raymond mill model can be integrated with a customized hot air drying function, which can simultaneously complete the drying of materials during the grinding process, significantly enhancing the processing capacity for high-moisture materials.

Ii. System Composition: Modular intelligent integration ensures stable and efficient operation

The Cronus Raymond mill adopts a highly integrated modular design. The entire system has a compact structure and a reasonable layout. It can be flexibly combined according to the customer’s production capacity requirements and working conditions. At the same time, it supports full-process automated control, significantly reducing manual operation and maintenance costs and ensuring the continuity and stability of production. The entire system is mainly composed of five core functional units:

- Crushing pretreatment unit

Equipped with Cronus’ self-developed jaw crusher or hammer crusher, large raw materials can be precisely crushed to the particle size that meets the feeding requirements of the grinding chamber (usually ≤30mm), laying a foundation for the subsequent grinding process and ensuring grinding efficiency and equipment operation safety.

- Lifting and storage unit

It is composed of a high-efficiency bucket elevator and a closed storage hopper, achieving smooth transportation and temporary storage of crushed materials. The equipment is equipped with an intelligent material level monitoring system, which can provide real-time feedback on material level information, automatically adjust the feeding rhythm, ensure continuous and stable supply to the core grinding unit, and avoid affecting production efficiency due to material interruption or excessive feeding.

- Core grinding powder selection unit

As the core hub of the entire set of equipment, this unit integrates three key devices: the main unit, the analyzer, and the blower. The main unit is equipped with high-quality grinding rollers, grinding rings, and scrapers inside, forged from wear-resistant alloy materials, significantly extending its service life. The analyzer adopts a high-precision impeller design, featuring high classification accuracy and flexible adjustment. The blower provides a stable airflow, ensuring the efficient coordination of powder conveying and classification, and achieving integrated operation of grinding and classification.

- Finished product collection and dust removal unit

The multi-stage collection and purification system is composed of a cyclone separator and a pulse bag dust collector. As the primary collection device, the cyclone separator can efficiently capture most of the qualified fine powder, ensuring the recovery rate of the finished product. As a secondary purification device, the pulse bag dust collector adopts high-end membrane-coated filter bags, with a dust removal efficiency of over 99.9%. It ensures that the exhaust gas emissions meet the latest environmental protection standards, while avoiding dust waste and balancing environmental protection and economy.

- Conveying and storage unit

Equipped with fully sealed screw conveyors and other conveying equipment, the collected finished powder is automatically and cleanly conveyed to the finished product silo or the designated packaging position. The entire conveying process adopts a sealed design, effectively preventing the powder from getting damp and contaminated, and ensuring the quality of the finished product.

Iii. Adaptability to Materials: Broad-spectrum compatibility features, focusing on the core field of non-metallic minerals

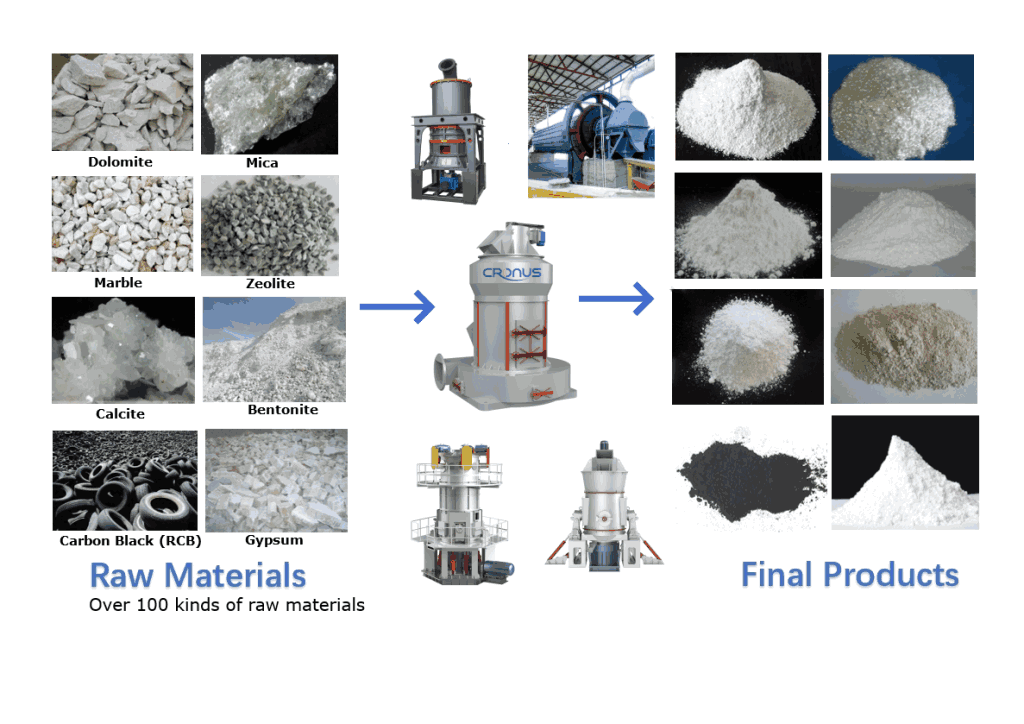

Cronus Raymond mill, with its optimized grinding structure design, has a wide range of material adaptability. Its core is suitable for non-flammable and non-explosive non-metallic minerals with a Mohs hardness of ≤7 and a moisture content of ≤6%. Based on market application scenarios, typical adaptable materials can be classified into four major categories:

- Building materials

Including limestone, gypsum, marble, calcite, etc., after grinding, they can be widely used in building materials fields such as cement production, putty powder processing, and architectural coating preparation. The finished powder has advantages such as uniform particle size and stable activity.

- Chemical materials

It covers calcium carbonate, talc, barite, dolomite, etc. After grinding, it can be used as a filler and additive in the production of chemical products such as plastics, rubber, coatings and inks, which can effectively improve product performance and reduce production costs.

- Metallurgical and mineral materials

Such as potassium feldspar, sodium feldspar, manganese ore, iron ore, etc., after grinding, can be used in fields such as metallurgical smelting auxiliary materials, ceramic glaze preparation, and glass production, meeting the strict requirements of the industry for the fineness and purity of materials.

- New materials

It includes kaolin, bentonite, diatomite, talcum powder, etc. After precise grinding, it can be applied in new material fields such as electronic ceramics, lithium battery materials, and high-end refractory materials, promoting the quality upgrade of the new material industry.

【 Not Applicable to the following materials 】:

High-hardness materials with a Mohs hardness > 7 (such as corundum, diamond), fibrous sticky materials (such as wood chips, fiberboard), flammable and explosive materials (such as aluminum powder, magnesium powder), and ultra-high moisture materials with a moisture content > 6%. For such materials, customized special grinding equipment from Shanghai Cronus should be selected.

Technical advantages and key points of operation and maintenance of Cronus Raymond Mill

Relying on its core technology research and development capabilities, Cronus Raymond mill has significant technical advantages over traditional equipment: the grinding efficiency is increased by 15% to 20% compared with traditional equipment, and the unit energy consumption is reduced by more than 10%. The uniformity of the finished product particle size is high, and the adjustment range is wide (80-400 mesh can be precisely regulated). Fully enclosed design + highly efficient dust removal system, with a 100% environmental protection compliance rate. The modular structure is convenient for installation, commissioning and maintenance, and the equipment failure rate is low.

To ensure the long-term stable operation of the equipment, the following key points should be noted during the operation and maintenance process: Regularly check the wear of vulnerable parts such as grinding rollers, grinding rings, and scrapers, and replace and maintain them in a timely manner; Strengthen the inspection of the sealing system to prevent powder leakage from affecting the production environment and the quality of finished products. Regularly calibrate the rotational speed of the analytical machine impeller and the pressure of the air system to ensure the classification accuracy and air flow balance. Standardize the implementation of equipment lubrication management and add special lubricating oil as required. Avoid overloading the equipment and strictly follow the operating procedures to control the feed volume and material moisture.

Cronus Raymond mill, with its mature and reliable technology, wide material compatibility and excellent economic and environmental benefits, has become the preferred equipment in the field of non-metallic mineral powder grinding. Relying on a complete R&D, production and after-sales system, Cronus can provide customers with a full-process solution from equipment selection, customized design to installation and commissioning, and operation and maintenance services, helping enterprises improve powder processing efficiency and achieve high-quality development.