Abstract: Overview of dolomite. What is dolomite? Dolomite is also known as dolomitic limestone, it is a carbonate mineral and one of the common rocks in the earth’s crust. Its crystal structure is similar to calcite, and it often takes the form of rhombohedrons, with crystal faces often curved into saddle shapes.

Overview of Limestone

What is dolomite?

Limestone is also known as travertine. It is a type of carbonate mineral and one of the common rocks in the Earth’s crust. Its crystal structure is similar to that of calcite, and it usually takes the form of a rhombohedron. The crystal faces often curve into a saddle shape.

The physical and chemical properties of dolomite

Limestone possesses both physical stability and chemical reactivity. Its key characteristics include:

Hardness: The Mohs hardness ranges from 3.5 to 4.0, which is considered medium hardness. It is easy to process and carve.

Density: 2.8 – 2.9 g/cm³. The relative density is moderate, making it convenient for transportation and usage.

Crystal structure: In the form of a rhombohedron, the crystals are often in a curved saddle shape, and the aggregates are mostly in granular or block-like forms.

Luster: Exhibits a glass-like luster, with a smooth surface and excellent reflective properties.

Color: Mainly grayish white, but may take on other colors such as grayish green, grayish yellow, or pink due to the presence of impurities.

Classification of dolomite

Calcite, as a widely existing mineral in nature, is classified mainly based on factors such as its formation process and chemical composition. According to the formation stage and composition, calcite can be divided into several types:

Congenital dolomite: Dolomite formed in the early stage of sedimentary lithification, with uniform and dense structure and fine grain size.

Diagenetic dolomite: Dolomite formed during diagenesis, where calcium carbonate is replaced by magnesium ions, featuring a fine-grained structure and evidence of the replacement process.

Post-depositional dolomite: Dolomite formed by the replacement of consolidated limestone by magnesium ions, featuring an uneven replacement structure and coarse-grained calcite particles.

The application of dolomite

Limestone, with its unique physical and chemical properties, abundant resource reserves and diverse processing methods, has shown great potential for wide application in fields such as environmental protection, refractory materials, ceramics, and others.

The grinding and deep processing of dolomite

The transformation of dolomite from basic minerals to high-value-added products cannot be achieved without the support of efficient and intelligent grinding equipment. The Shanghai KoliRik ultra-fine ring roller grinding machine and Raymond grinding machine form the core of the “low energy consumption, high precision, zero pollution” grinding ecosystem.

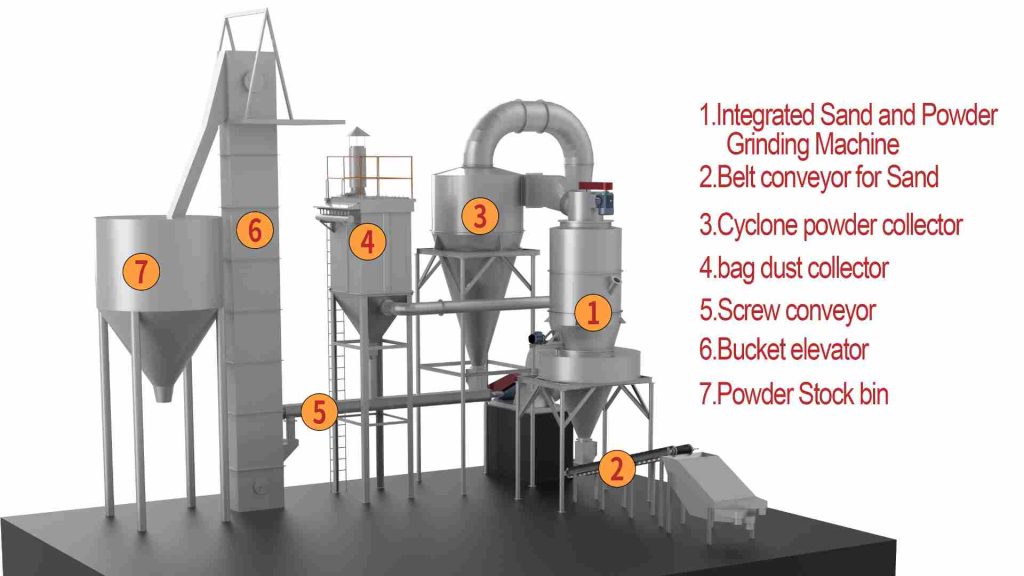

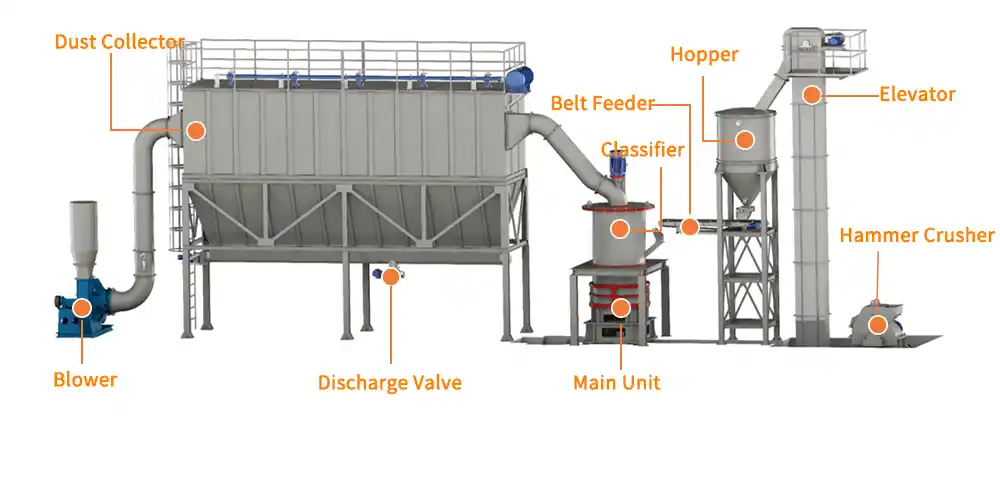

The processing procedure of barite using the Raymond mill

he raw materials are uniformly and quantitatively continuously fed into the main grinding chamber by the variable-frequency belt feeder for grinding. The ground materials are sent into the classifier by the fan airflow for classification. Under the action of the classifier, the materials that do not meet the fineness requirements fall back into the grinding chamber for re-grinding, while the qualified materials are carried by the airflow through the pipeline and enter the cyclone collector for separation and collection. Then, they are discharged through the discharge device to become the finished powder. The separated airflow passes through the return air duct at the top of the cyclone collector and enters the fan. This production system operates under negative pressure and closed conditions, and is equipped with a pulse dust collector to prevent dust from spilling out. It complies with national environmental protection standards.

The processing procedure of dolomite by ultra-fine ring roller mill

The motor drives the reducer to rotate the grinding disc. The materials are sent into the center of the grinding disc through the lockwind feeding equipment. Under the action of centrifugal force, they move to the edge of the grinding disc and enter the grinding roller path. Under the pressure of the grinding rollers, the materials are crushed by being squeezed, ground and sheared. At the same time, hot air is ejected from the wind ring at high speed, blowing the powderized materials up. Coarse particles are blown back for re-grinding, the suspended materials are dried, and the fine powder enters the separator for classification. The qualified fine powder is discharged with the airflow and collected by the dust collection equipment. The coarse powder falls back onto the grinding disc under the action of the separator and is re-grinded together with the new materials, completing the grinding operation in a cycle.