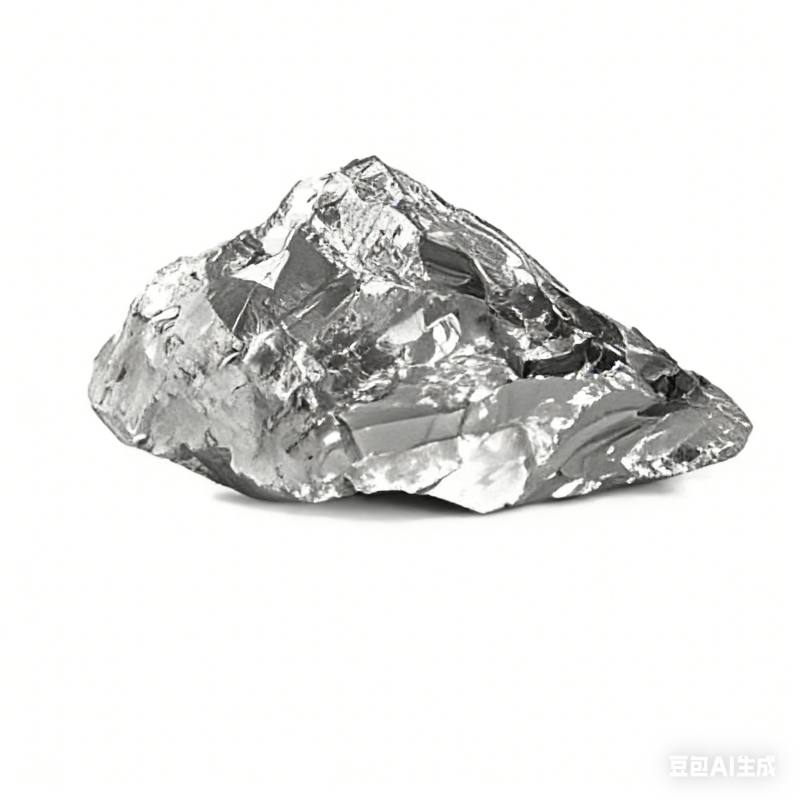

High-ice nickel is a sulfide eutectic of nickel, copper, cobalt, iron and other metals obtained from nickel concentrate through primary smelting in electric and converter furnaces, with an ingot appearance. Single weight: 1.5-4.0 tons; High-ice nickel is brittle and its cross-section has a bright metallic luster. High-ice nickel can be used to produce electrolytic nickel, nickel oxide, nickel-iron, nickel-containing alloys and various nickel salts. With special treatment, it can also be directly used in steelmaking.

The grinding process flow of high-ice nickel

The grinding process of high ice nickel is generally divided into three types: coarse powder processing of high ice nickel (0-3MM), fine powder processing (20 mesh -400 mesh), and deep processing of ultra-fine powder of high ice nickel (400 mesh -3250 mesh). Depending on the material, the degree of demand and the application field, the required production process varies and needs to be operated flexibly. For more details, please consult our online customer service.

Phase One: Crushing

The large pieces of high-ice-nickel materials are crushed by the crusher to the feed fineness that can enter the grinding mill (15mm-50mm).

Phase Two: Grinding into powder

The crushed small pieces of high-ice nickel materials are conveyed to the silo by the elevator, and then evenly and quantitatively sent into the grinding chamber of the mill by the conveying equipment for grinding.

For fine powder processing, vertical roller mills and European-style mills are generally selected. For ultra-fine powder processing, ultra-fine vertical mills and ring roller micro powder mills are generally chosen. For coarse powder processing, European-style coarse powder mills and straight-through centrifugal mills are selected.

Phase Three: Grading

The ground materials are classified by the classifier. The unqualified powder is returned to the main machine for re-grinding after being classified by the classifier.

Phase Four: Gathering followers

The powder that meets the fineness requirements is carried by the airflow through the pipeline into the dust collector for separation and collection. The collected finished powder is sent to the finished product silo through the discharge port by the conveying device, and then uniformly packaged by powder tank trucks or automatic packaging machines.