Contents Catalog

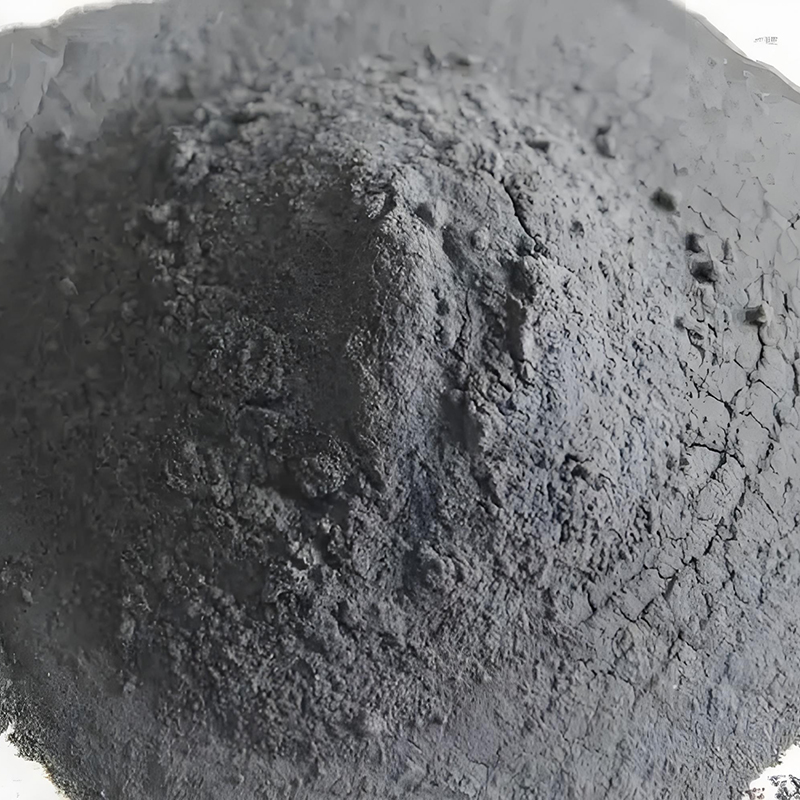

What is Aluminium slag?

Aluminum Slag – During the processing of aluminium, a solid waste called aluminium slag is produced, which contains a high amount of aluminium and thus has significant recycling value. However, due to the fact that aluminium slag reacts with water to produce ammonia gas, it has reactive hazardous characteristics. As of January 1, 2021, the “List of Hazardous Wastes” (2021 Edition) clearly defines aluminium dross as a hazardous waste. So, what exactly is aluminium dross and how should it be handled?

Aluminum slag is the scum and slag that floats on the surface of molten aluminum during the electrolytic aluminum, casting aluminum, and recycled aluminum smelting processes, including the remaining residue after subsequent treatments such as roasting and ball milling.

Aluminum slag processing flowchart

The basic process flow for recovering metallic aluminum from commonly used aluminum dross is: crushing – grinding milling – screening.

- Crushing: The recycled aluminum dross and foundry waste molding sand are conveyed through the silo by a closed conveyor to the ball mill for grinding.

- Special for Aluminum slag grinding milling raymond mill: Further ball milling is carried out on the aluminum ash residue that has undergone the crushing step.

- Screening: Generally, a drum screen is used. The screening drum rotates at a certain speed, and the material passes through the screening drum from top to bottom to be separated. Fine materials are discharged from the lower front end of the screening drum, while coarse materials are discharged from the lower tail end of the screening drum. It has a simple structure, large processing capacity, and is suitable for both dry and wet materials. The drum screen can effectively screen out metal aluminum particles of different particle sizes, and the screened aluminum is relatively clean. After screening, the materials are divided into aluminum chips/particles and powder (secondary aluminum ash). The aluminum chips/particles can be sold to aluminum processing enterprises for remelting, and the remaining powder mainly contains alumina and can be sent to cement plants as auxiliary materials.

The process flow of aluminium dross treatment should ensure that the entire recycling process is safe and dust-free, and does not cause secondary pollution to the environment.

At present, the special aluminum ash grinding mill produced by Cronus Company is being installed intensively in Zhengzhou, Henan Province. It is learned that this grinding mill has been upgraded based on the Raymond mill in accordance with the characteristics of aluminum ash. It adopts super wear-resistant high-strength materials and can process aluminum ash to 400 mesh. The designed output is 8 tons per hour. After comparison, the average service life of this Raymond mill in processing aluminum ash has been increased by 2 times compared with the traditional grinding mill. Currently, our company’s Raymond mill equipment has been widely applied in the aluminum ash industry, and its market share in this field exceeds 50%.

Our company’s aluminum slag grinding machine is currently under installation:

How should the aluminum waste be disposed of?

Aluminum slag, when exposed to water, will undergo a reaction and release ammonia gas. It is also prone to spontaneous combustion when damp. Therefore, when enterprises handle aluminum slag, they need to follow the relevant requirements for managing hazardous waste. They should report and register the generated hazardous waste, such as aluminum slag, and properly dispose of it to ensure environmental safety.

- Establish storage facilities following regulations, set up identification signs, implement protective measures, conduct classified collection and storage, and ensure that the management records are complete.

II. The requirements for the full life-cycle monitoring system of hazardous waste should be implemented. Management ledgers should be established to enable traceability and queryability of hazardous waste.

III. Dispose of hazardous waste by the law to qualified waste disposal units. Verify the legal person qualifications and technical capabilities of the entrusted party, and stipulate corresponding pollution prevention requirements in the contract.