Contents Catalog

The main ways for power plants to reduce sulfur dioxide emissions include coal washing and selection, clean coal combustion technology and flue gas desulfurization. At present, coal washing and selection technology can only remove part of inorganic sulfur, and there is still a lack of economically feasible removal solutions for organic sulfur.

Although clean coal combustion technology has mature commercial applications, its single-unit capacity is generally small, and the investment cost is high with strict technical requirements. Therefore, it is difficult to achieve large-scale promotion in the short term. After nearly 30 years of development, flue gas desulfurization has become a mature and stable technology, and various flue gas desulfurization devices have been widely applied in coal-fired power plants around the world.

The main uses of desulfurization

Limestone-gypsum method (wet FGD)

Process features: The limestone-gypsum method has extensive potential for commercial development. Its absorbent resources are abundant and the cost is low. Meanwhile, the waste residue can be recycled into commercial gypsum. As the absorbent slurry in the absorption tower is repeatedly in contact with the flue gas through the circulating pump, this method has a very high absorbent utilization rate, a relatively low calcium-sulfur ratio, and the desulfurization efficiency can exceed 95%.

In-furnace calcium injection tail humidification flue gas desulfurization process (LIFAC)

Process features: This process injects limestone powder into coal-fired boilers within the suitable temperature range and adds an activation reactor after the boiler air preheater to effectively remove SO2 from flue gas. This method requires less investment, occupies a small area and discharges no wastewater, making it highly suitable for the renovation of old power plants.

Flue gas circulating fluidized bed desulfurization process (dry FGD)

Process features: This process consists of absorbent preparation, absorption tower, desulfurization ash recirculation, dust collector and control system, etc. Generally, dry slaked lime powder is used as the absorbent, but other dry powders or slurries that can react with carbon dioxide can also be used as substitutes.

Main applicable industries

Fields such as roads, chemical engineering, cement, building materials and construction.

Desulfurization processing production process flow

The efficiency of Sulphurization by the “limestone-gypsum method” usually exceeds 95%, making it the most widely used Sulphurization technology globally.

The first stage

Mineral processing involves crushing the limestone in the raw materials and grinding it into fine powder with a mesh size of 200-300.

The second stage

The ground limestone powder is mixed with water to make a slurry, and then pumped into the absorption tower to be fully mixed and come into contact with the flue gas.

The third stage

Sulfur dioxide in the flue gas undergoes an oxidation reaction with calcium carbonate in the slurry and the air blown in from the bottom of the tower to form hard silicates. When the product reaches a certain saturation, it will crystallize to form dihydrate gypsum. The gypsum slurry discharged from the absorption tower needs to undergo concentration and dewatering treatment to reduce its moisture content to below 10%.

The Fourth stage

The dehydrated gypsum is sent to the storage silo for stacking by conveying equipment, while the treated flue gas needs to first pass through a demister to remove droplets, then be heated and raised in temperature by a heat exchanger, and finally be discharged into the large gas through a chimney.

The vertical mill produced by our company is needed in the desulfurization process of power plants.

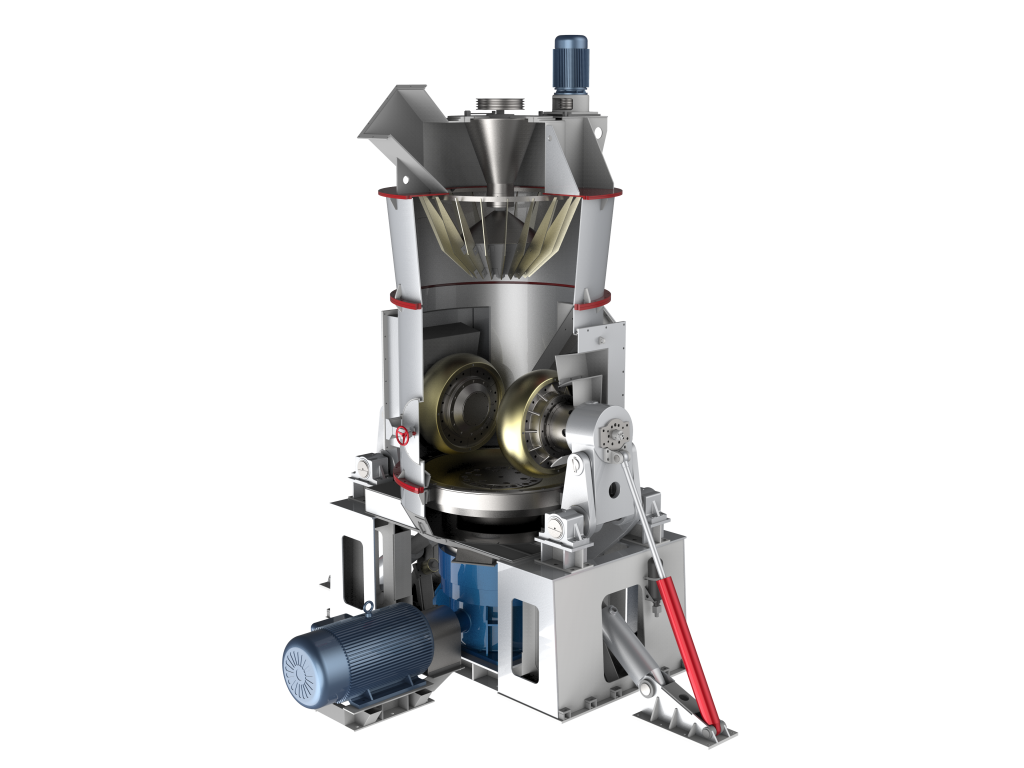

Vertical mill

The CRLM vertical grinding mill is a new type of grinding equipment designed by Cronus Company based on various vertical grinding materials at home and abroad, by introducing advanced foreign technologies and combining the characteristics of China’s cement industry. It consists of multiple parts such as the main machine, classifier, blower, pipeline system, as well as hydraulic lubrication system and electrical control system.

This equipment is widely used in industries such as power metallurgy solid waste treatment, cement manufacturing, and non-metallic and non-ferrous metal mining. It can perform fine grinding on various materials such as raw materials, clinker, and high-efficiency environmentally friendly materials, ranging from high-moisture (moisture content 10-12%) to dry materials (moisture content < 1%). The fineness of the products varies from coarse to fine, with a particle size range of 80 to 600 mesh. The production capacity ranges from 6 to 240 tons per hour, varying according to different models.

| Parameter | Specification |

|---|---|

| Fineness | 80~600 mesh |

| Production capacity | 60~80 t/h |

| Application | The equipment is suitable for industries such as cement, metallurgy, chemical industry, solid waste treatment, non-metallic minerals, non-ferrous metals, and coal grinding in power plants. It is used for grinding materials including cement raw meal, clinker (slag), coal, gypsum, pyrophyllite, calcite, quartz, zinc, tin, etc. |

This equipment is widely used in multiple industry fields such as power metallurgy solid waste treatment, cement manufacturing, and non-metallic and non-ferrous metal mining. It has a good effect on various materials such as raw materials and clinker, as well as by-products generated by pulse dust collectors.

Parameter Comparison Table

| Model | CRLM1500K | CRLM1700K | CRLM2000K | CRLM2200K | CRLM2400K | CRLM2800K | CRLM3400K |

|---|---|---|---|---|---|---|---|

| Capacity (t/h) | 6-8 | 10-12 | 15-22 | 25-28 | 24-38 | 45-50 | 60-80 |

| Max. Feed Size (mm) | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| Slag Moisture Content (%) | <12 | <12 | <12 | <12 | <12 | <12 | <12 |

| Product Specific Surface Area (m²/kg) | ≥420 | ≥420 | ≥420 | ≥420 | ≥420 | ≥420 | ≥420 |

| Product Moisture Content (%) | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| Main Motor Power (kW) | 280 | 400 | 500 | 800 | 900 | 1600 | 2400 |

Note: Grinding Work Index (Bond Index) ≤ 12 kWh/t

- The above data is for reference only. Please refer to the product itself or the product manual for specific information.