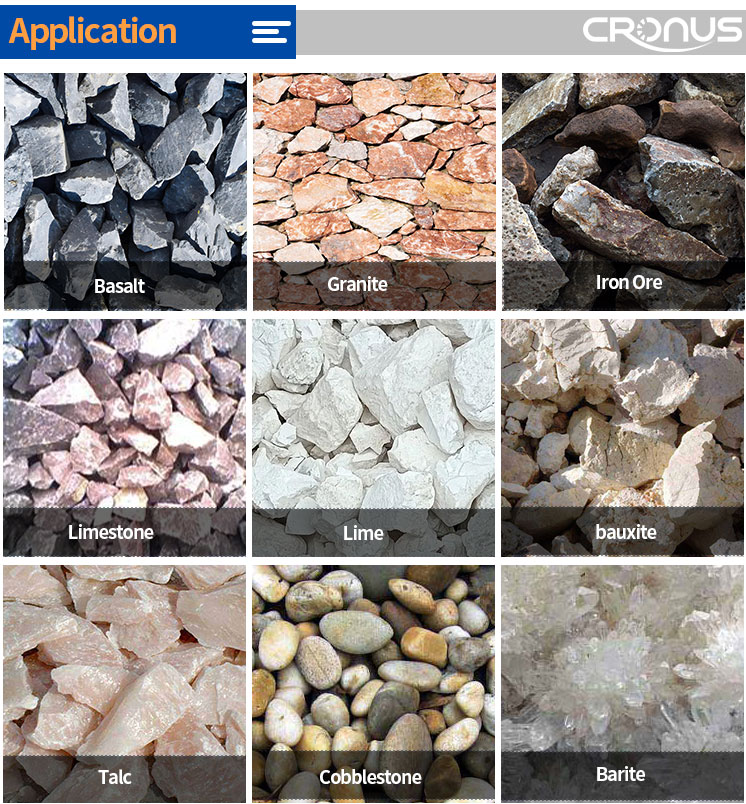

Hydraulic cone crusher is a high-performance crusher designed by absorbing modern technology and combining the performance of metal materials. It is mainly used in the second-stage crushing and third-stage crushing links in metal mining and construction sand and gravel processing. Because of its crushing It has strong capacity and large output, and is more often used for crushing medium-hard materials.

Hydraulic Cone Crusher Working Principle

The cone crushing cone performs a swing motion under the driving action of the eccentric sleeve, driving the crushing wall to squeeze and grind the material between the rolling mortar wall. According to the lamination theory, the material is subject to forces in multiple directions, and according to its own texture After being crushed and polished, stable stone particles are formed. Those that meet the discharging requirements fall from the swing gap of the crushing wall, and the remaining materials continue to be crushed until the requirements are met.

Technical Parameters

| Model | Chamber Size (Coarse/Fine) | Max Feed Size (mm) | Min Discharge Size (mm) | Capacity (t/h) | Power (kW) |

|---|---|---|---|---|---|

| HPT100 | C1 | 140 | 19 | 50-140 | 90 |

| C2 | 100 | 13 | 50-140 | 90 | |

| M | 70 | 9 | 50-140 | 90 | |

| F1 | 50 | 9 | 50-140 | 90 | |

| F2 | 20 | 6 | 50-140 | 90 | |

| HPT200 | C2 | 185 | 19 | 90-250 | 160 |

| M | 125 | 16 | 90-250 | 160 | |

| F1 | 95 | 13 | 90-250 | 160 | |

| F2 | 75 | 10 | 90-250 | 160 | |

| HPT300 | C1 | 230 | 25 | 110-440 | 250 |

| C2 | 210 | 19 | 110-440 | 250 | |

| M | 150 | 16 | 110-440 | 250 | |

| F1 | 105 | 13 | 110-440 | 250 | |

| F2 | 80 | 10 | 110-440 | 250 | |

| HPT400 | C1 | 295 | 30 | 135-630 | 315 |

| C2 | 251 | 25 | 135-631 | 315 | |

| M | 196 | 20 | 135-632 | 315 | |

| F1 | 110 | 13 | 135-633 | 315 | |

| F2 | 90 | 10 | 135-634 | 315 | |

| HPT500 | C1 | 330 | 38 | 220-790 | 400 |

| C2 | 290 | 30 | 220-790 | 400 | |

| M | 210 | 22 | 220-790 | 400 | |

| F1 | 135 | 16 | 220-790 | 400 | |

| F2 | 95 | 13 | 220-790 | 400 | |

| HPT800 | C1 | 350 | 38 | 310-1200 | 630 |

| C2 | 299 | 32 | 310-1200 | 630 | |

| M | 265 | 25 | 310-1200 | 630 | |

| F1 | 220 | 16 | 310-1200 | 630 | |

| F2 | 150 | 13 | 310-1200 | 630 |

Product Advantage

1、Increased production capacity and efficiency

The main shaft is fixed and the eccentric sleeve rotates around the main shaft, which can withstand greater crushing power. Reasonable coordination of eccentricity, cavity shape and motion parameters greatly improves production capacity and work efficiency.

2、Adopt layer compression crushing mechanism

It is designed using the layer compression crushing principle, so that crushing occurs between materials. It has high crushing efficiency and excellent particle shape. It is a partner for producing high-quality aggregates.

3、Realize fully automatic intelligent control

The electrical system adopts Siemens PLC and touch screen control system, ABB low-voltage control components, Siemens high-voltage motors; dual lubricating oil pumps, dual electric heaters, dual air coolers, and realizes fully automatic intelligent control.

4、Enhanced control system functions

It adopts visual sensor values, visual and freely configurable alarm solutions, and a more flexible Internet measurement and control docking solution.

5、Stable and intelligent operation capability

Convenient operation and maintenance, adding automation functions such as lubrication oil return flow monitoring, horizontal axis speed monitoring, vibration monitoring, automatic feeding control, etc., extend the service life of the equipment and make the crushing system more stable and intelligent.