Coal is a vital energy resource and is extensively utilized in various industries, including metallurgy, chemical engineering, cement production, power generation, heating systems, thermal supply, and boiler operations. It serves as a key raw material for producing clean coal powder, activated carbon, humic acid, and other value-added products. The future prospects for the clean, efficient utilization of coal and its deep processing are promising.

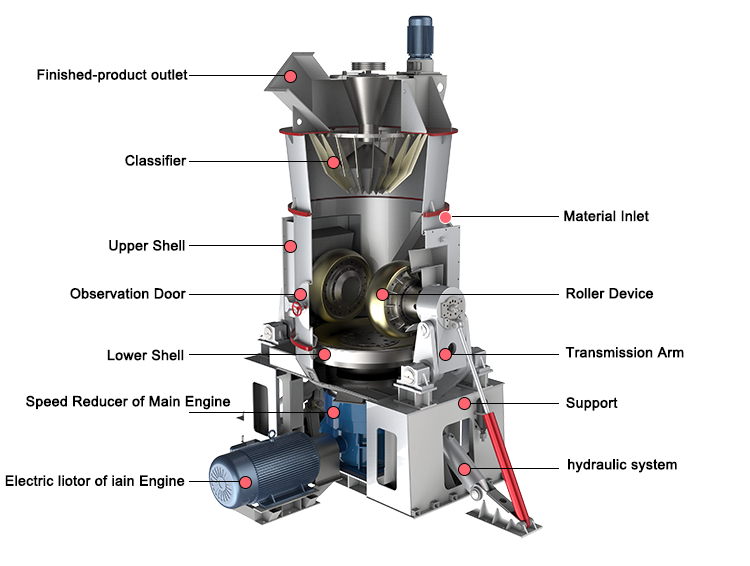

CRLM vertical grinding mill

The CRLM vertical grinding mill is a newly developed grinding system engineered by Cronus through comprehensive research on domestic and international vertical grinding technologies, incorporating advanced foreign innovations and tailored to the specific requirements of China’s cement industry. This integrated system comprises a main unit, classifier, blower, pipeline network, hydraulic and lubrication systems, pulse dust collector, and an automated electrical control system.

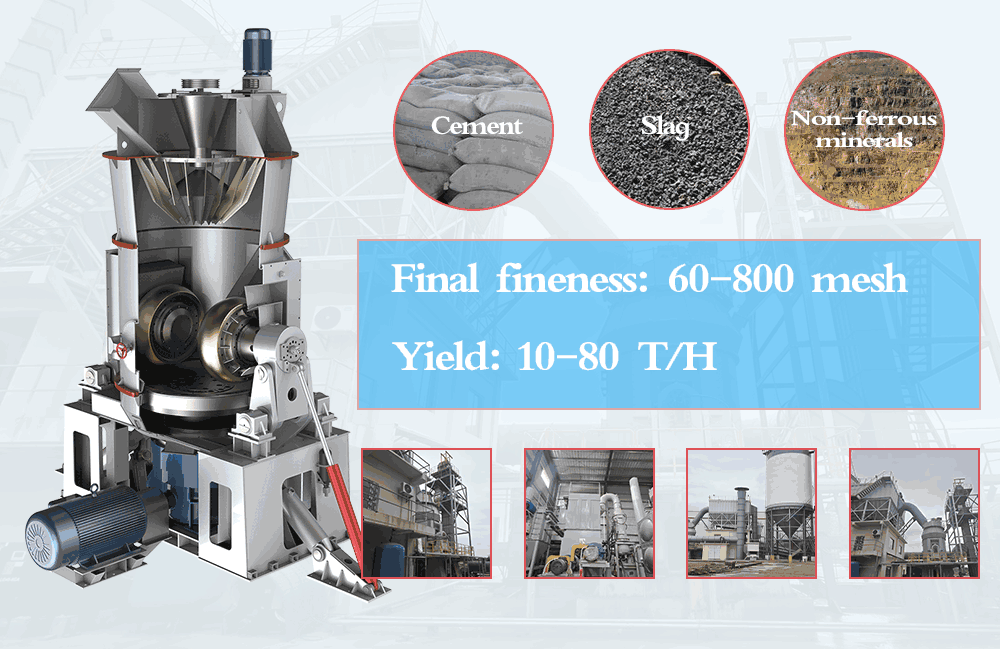

This equipment is extensively utilized across industries including power generation, metallurgy, solid waste processing, cement production, chemical manufacturing, non-metallic minerals, and non-ferrous metal mining. It is capable of grinding a wide range of materials such as raw meal, clinker, desulfurized limestone powder, slag, steel slag, manganese ore, coal, and phosphate rock. The mill accommodates feed materials with moisture content ranging from high (10%–12%) to low (below 1%), and processes materials from highly abrasive to easily grindable types. Product fineness can be adjusted between 80 and 600 mesh, with hourly production capacities ranging from 6 to 240 tons, depending on the model configuration.

The CRLM vertical grinding mill is widely applied in sectors such as energy, metallurgy, waste treatment, cement, chemicals, and mineral processing for grinding raw materials including cement raw meal, clinker, desulfurized limestone, slag, steel slag, manganese ore, coal, and phosphate rock.

Process Flow of Coal Powder Grinding

Grinding Stage

Prior to grinding, moist coal is first dried and then continuously and uniformly fed into the grinding chamber of the main mill for pulverization. The resulting fine powder is carried by fan-generated airflow to a classifier, where particle size separation occurs. Particles meeting the specified fineness requirements are directed through the outlet duct to the collection stage.

Collection Stage

The ground coal particles are transported by airflow to the classifier, after which those of acceptable fineness are conveyed via ductwork to an explosion-proof pulse dust collector. Within the collector, particulate matter is separated from the gas stream through inertial forces and subsequently discharged into the ash hopper. The remaining dust-laden gas proceeds to the bag filtration zone. As filtration progresses, dust accumulates on the surface of the filter bags. At predetermined intervals, solenoid valves initiate a pulse-jet cleaning process, injecting compressed air to dislodge accumulated dust. All collected material falls into the ash hopper for centralized collection and discharge.

Conveying Stage

The finished coal powder, once collected by the explosion-proof dust collector, is transferred via screw conveyor to a plate chain elevator, which elevates the material into the final product storage silo. Dust-laden gases generated within the silo are captured by a roof-mounted dust collector. The purified gas is then released into the atmosphere, while the processed coal powder is stored in the silo for subsequent distribution.

Finished product stage

The resulting pulverized coal product is ready for direct delivery to customer sites and requires no further downstream processing prior to use.

For any questions about the grinding mill, just make a phone call or send an email. Our professional service team is not only experts in problem-solving but also your reliable partner, always ready to work with you to address challenges and create value for your business growth. We are here, always at your service