Contents Catalog

PEC Jaw crusher, also known as jaw crusher, is a commonly used coarse crushing equipment, widely used in mining, metallurgy, building materials, highways, railways, water conservancy and chemical industries, for primary crushing of various ores and bulk materials. This article will give a comprehensive introduction to jaw crushers from the aspects of basic structure, working principle, application range, equipment advantages, maintenance and accessories supply.

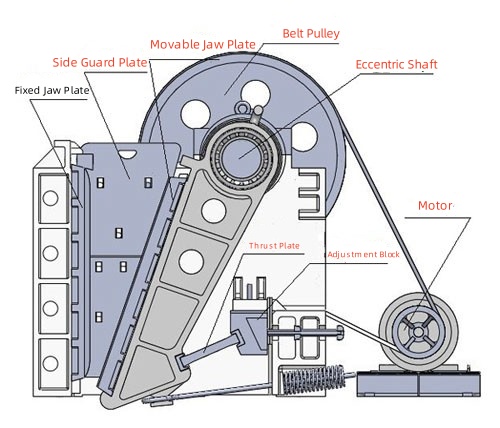

Basic structure of PEC jaw crusher

The jaw crusher is mainly composed of frame, movable jaw, static jaw, jaw plate, eccentric shaft, flywheel, adjustment device, lubrication system, etc.

- Frame: The load-bearing basic structure of the entire crusher, made of high-quality cast steel or welded structure, sturdy and durable.

- Moving jaw and static jaw: The movable jaw moves periodically relative to the static jaw driven by the eccentric shaft to complete the crushing action.

- Jaw plate (liner): Installed on the movable jaw and static jaw, used for direct contact and crushing materials, usually made of high manganese steel.

- Eccentric shaft and flywheel: The eccentric shaft is the core component of the drive mechanism, and cooperates with the flywheel to maintain smooth operation.

- Adjustment device: used to adjust the size of the discharge port and control the particle size of the finished product.

- Lubrication system: Lubricate moving parts such as bearings to ensure long-term stable operation.

Working Principle of PEC Jaw crusher

The working mode of the jaw crusher is to simulate the process of animals chewing food. The material is fed into the crushing chamber through the feeder. Driven by the movable jaw, the material is clamped between the movable jaw and the static jaw and is squeezed and sheared, thus being crushed. When the movable jaw is away from the static jaw, the crushed material is discharged from the bottom under the action of its own gravity.

The whole process is carried out continuously to achieve periodic crushing of the material.

The jaw crusher is suitable for processing various ores and rocks with compressive strength not exceeding 320MPa, including but not limited to:

Maintenance of PEC Jaw crusher

In order to ensure long-term stable operation of the equipment, the following points should be noted:

- Daily inspection: Before starting, check whether the fasteners are loose, whether the lubricating oil is sufficient, and whether all parts are normal.

- Operation monitoring: Observe the current, voltage, vibration and other parameters during operation. If any abnormality occurs, stop the machine for investigation in time.

- Regular lubrication: Bearings and other moving parts need to be regularly filled with grease to avoid dry grinding.

- Replacement of wearing parts: Jaw plates, guard plates, etc. should be replaced in time after wear to maintain crushing efficiency.

- Cleaning work: After stopping, remove the residual materials in the crushing chamber to keep the equipment clean and tidy.

Cronus can provide you with a full range of jaw crusher accessories, including:

Technical Parameters of PEC Jaw crusher

| Overall Dimensions (mm) | PEC96 | PEC106 | PEC120 | PEC125 | PEC140 | PEC160 | PEC200 | ||||||||

| A | 930 | 1060 | 1200 | 1250 | 1400 | 1600 | 2000 | ||||||||

| B | 580 | 700 | 870 | 950 | 1070 | 1200 | 1500 | ||||||||

| C | 1755 | 2030 | 2687 | 2800 | 3010 | 3700 | 4040 | ||||||||

| D | 2880 | 3320 | 3670 | 4100 | 4400 | 5900 | 6700 | ||||||||

| E | 1610 | 2075 | 3272 | 3440 | 3950 | 4580 | 4950 | ||||||||

| F | 1460 | 2005 | 3882 | 2980 | 3140 | 3750 | 4465 | ||||||||

| G | 755 | 1135 | 2008 | 2100 | 2260 | 2650 | 2800 | ||||||||

| H | 2500 | 2630 | 2724 | 3470 | 3755 | 4280 | 4870 | ||||||||

| I9 | 465 | 700 | 1569 | 980 | 1050 | 1300 | 1400 | ||||||||

| Copper Ore Crusher | KE96 | KE106 | KE120 | KE125 | KE140 | KE160 | KE200 | ||||||||

| Technical Parameters | |||||||||||||||

| Power | 90Kw | 110Kw | 160Kw | 160Kw | 200Kw | 250Kw | 400Kw | ||||||||

| Rotation Speed | 330Rpm | 280Rpm | 230Rpm | 220Rpm | 220Rpm | 220Rpm | 200Rpm | ||||||||

| Crusher Weight | 9759Kg | 14350Kg | 26000Kg | 37970Kg | 47120Kg | 71330Kg | 121510Kg | ||||||||

| Working Weight | 11870Kg | 17050Kg | 29300Kg | 43910Kg | 54010Kg | 83300Kg | 137160Kg | ||||||||

| Feed Opening | |||||||||||||||

| Width | 930mm | 1060mm | 1200mm | 1250mm | 1400mm | 1600mm | 2000mm | ||||||||

| Depth | 580mm | 700mm | 870mm | 950mm | 1070mm | 1200mm | 1500mm | ||||||||

| KE CRUSHER Capacity | KE96 | KE106 | KE120 | KE125 | KE140 | KE160 | KE200 | ||||||||

| Particle Size (mm) | Discharge Size (mm) | t/h | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0-150 | 100 | 175-225 | 205-265 | 235-325 | 290-380 | ||||||||||

| 0-185 | 125 | 220-280 | 255-325 | 285-395 | 350-455 | 385-500 | |||||||||

| 0-225 | 150 | 265-335 | 305-385 | 340-475 | 410-535 | 455-590 | 520-675 | ||||||||

| 0-260 | 175 | 310-390 | 355-450 | 385-540 | 470-610 | 520-675 | 595-775 | 760-990 | |||||||

| 0-300 | 200 | 395-500 | 530-690 | 590-765 | 675-880 | 855-1110 | |||||||||

| 0-340 | 225 | 590-770 | 655-850 | 750-975 | 945-1230 | ||||||||||

| 0-375 | 250 | 650-845 | 725-945 | 825-1070 | 1040-1350 | ||||||||||

| 0-410 | 275 | 900-1170 | 1130-1470 | ||||||||||||

| 0-410 | 300 | 980-1275 | 1225-1590 | ||||||||||||

For more product information or to obtain the jaw crusher model suitable for you, please contact Cronus professional sales and technical team, we will provide you with a one-stop mining crushing solution.