Contents Catalog

Key points of processing basalt with Raymond mill

Equipment selection

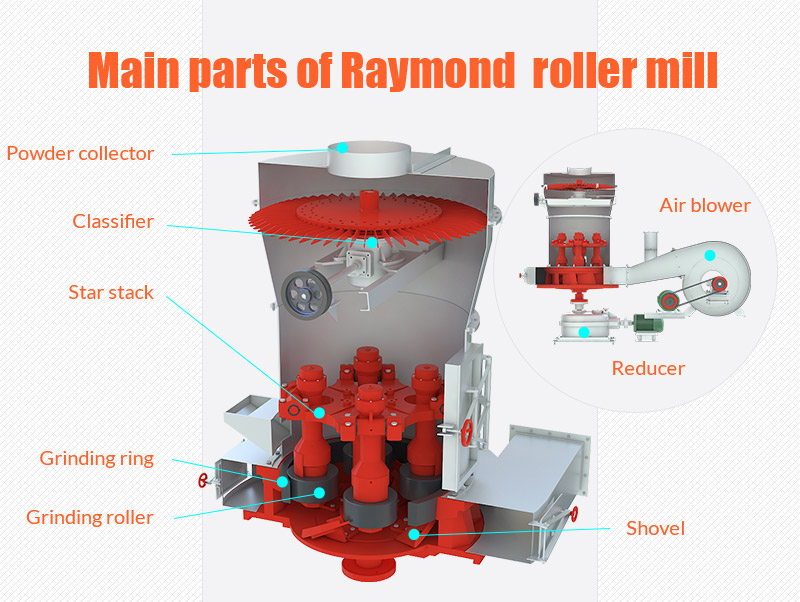

Basalt has a high hardness. During grinding, it causes severe wear to grinding components such as grinding rollers, grinding rings, and scrapers, shortening the service life of equipment and increasing maintenance costs. It may also cause metal debris to mix into the product, affecting its purity. When selecting equipment, it is necessary to choose large-sized and high-power Raymond mills, such as the 5R and 6R series. These mills have large grinding roller diameters, strong grinding pressure, and high main motor power, which can handle the grinding of hard materials.

Material of grinding components

The grinding rollers and grinding rings are cast from special wear-resistant alloy steels such as high manganese steel and high chromium alloy, which have several times the wear resistance of ordinary steel and can extend the replacement cycle. The scraper (base) is also made of wear-resistant materials to ensure the feeding capacity.

Analysis machine

When choosing a high-precision and high-stability variable frequency speed control analysis machine to process high-mesh powder, the fineness of the product can be controlled by adjusting the rotational speed to meet the demands of different industries.

Fan

It is equipped with a high-volume and high-pressure fan to ensure the timely extraction of qualified fine powder, forming a smooth air circulation. The appropriate air volume guarantees the efficient and stable grinding of powder.

The processing technology of basalt by Raymond mill

Feed particle size

The ideal feed particle size is below 15-25mm. Large pieces of basalt need to be pre-crushed by a jaw crusher or similar equipment; otherwise, it will increase the grinding burden, leading to low output or even equipment jamming.

Feeding speed

Maintain uniform, stable and continuous feeding. Excessive feeding will clog the grinding chamber and increase the current of the main machine. Insufficient feeding will cause the grinding rollers and grinding rings to come into direct contact, resulting in severe wear. The rhythm can be precisely controlled by an automatic feeder.

Air volume and air pressure

The air volume affects the movement state of the material in the grinding chamber. If the air volume is too large, the product will become coarser, with high output but poor quality. When the air volume is too small, the output decreases, the equipment heats up, and energy consumption increases. The combination of air pressure and air volume affects the grinding effect. According to the target fineness, the speed of the analyzer should be matched to find the optimal opening of the air door.

Analysis machine rotational speed

The higher the rotational speed, the finer the particles sorted. When processing high-mesh powder, high-speed rotation is required. However, the speed adjustment needs to be coordinated with the air volume; otherwise, it will affect the air separation efficiency.

The application of Raymond mill in processing basalt

Building materials

It is commonly used in the production of concrete aggregates, asphalt aggregates, rock wool, etc., with a fineness of 80-200 mesh. Adding concrete can improve mechanical properties, enhance compressive and flexural strength, reduce permeability, increase resistance to chloride ion erosion, and extend the service life of the project.

Casting auxiliary materials

As a “new sand substitute” for casting molding sand, with a fineness of 200-325 mesh, it can improve the performance of molding sand and enhance the quality of castings.

Ceramic glaze

Pursuing a particle size of 325-800 mesh or even finer, it brings unique properties and colors to the glaze. After high-temperature firing, it can produce kiln change colors, endowing ceramic products with a simple and natural beauty.

Plastic and rubber fillers

Fineness: 600-1250 mesh. A classification system needs to be properly configured. Adding it to plastics can enhance tensile strength and heat distortion temperature.

Summary

When processing basalt with a Raymond mill, the equipment selection should be large-sized and high-power, the grinding components should be made of special wear-resistant materials, the analyzer should be selected with high-precision variable frequency speed regulation, and the fan should be equipped with a large air volume and high pressure. In terms of process, pay attention to the coordination of feed particle size, feeding speed, air volume and pressure, and the rotational speed of the analyzer.