Contents Catalog

What is Raymond Bowl Mill?

Raymond bowl mill, also known as Raymond mill, Raymond bowl mill pulverizer etc, is a widely used powder grinding equipment. The following introduces it from aspects such as its basic structure, working principle, and application scope:

Basic Structure of Raymond Bowl Mill

Main Machine: It is the core part of the Raymond bowl mill, consisting of the frame, air inlet volute, scraper, grinding roller, grinding ring, housing, and motor. The grinding roller and grinding ring are the components directly used for grinding materials. The motor drives the grinding roller to roll on the grinding ring through the transmission device.

Analyzing Machine: Also called the powder separator, it is located above the main machine and is used for classifying the ground materials. By adjusting parameters such as the rotation speed of the analyzing machine, the fineness of the finished materials can be controlled.

Blower: It provides the airflow power for the entire system, enabling the ground materials to rise and enter the analyzing machine for classification under the action of the airflow, and forming a circulating airflow within the system.

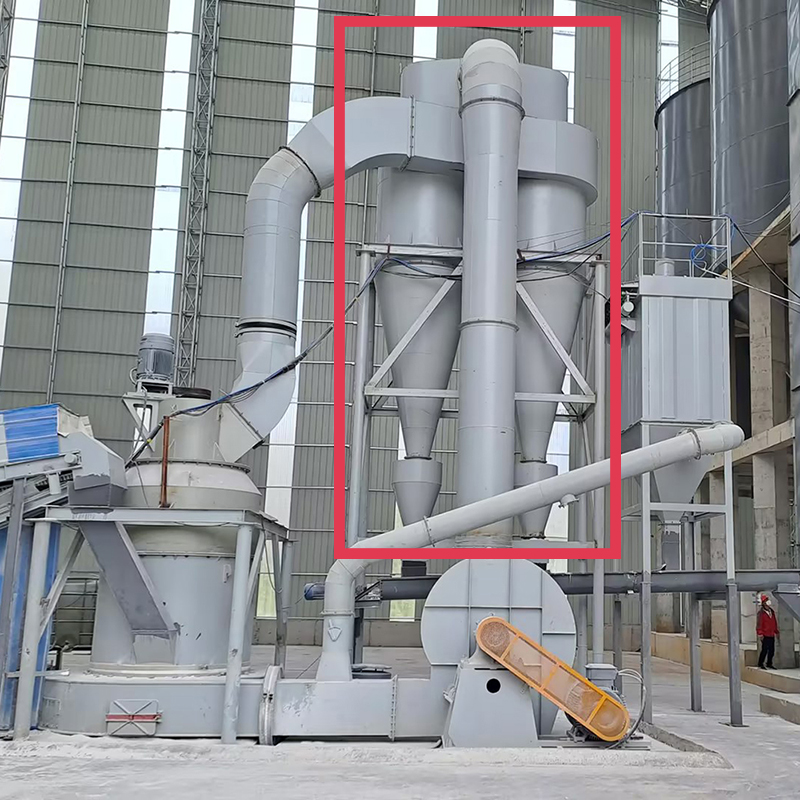

Finished Product Cyclone Separator: It separates the qualified fine powder classified by the analyzing machine from the airflow and collects it as the finished product. The airflow then returns to the blower through the return air duct at the upper end of the cyclone separator to form a cycle.

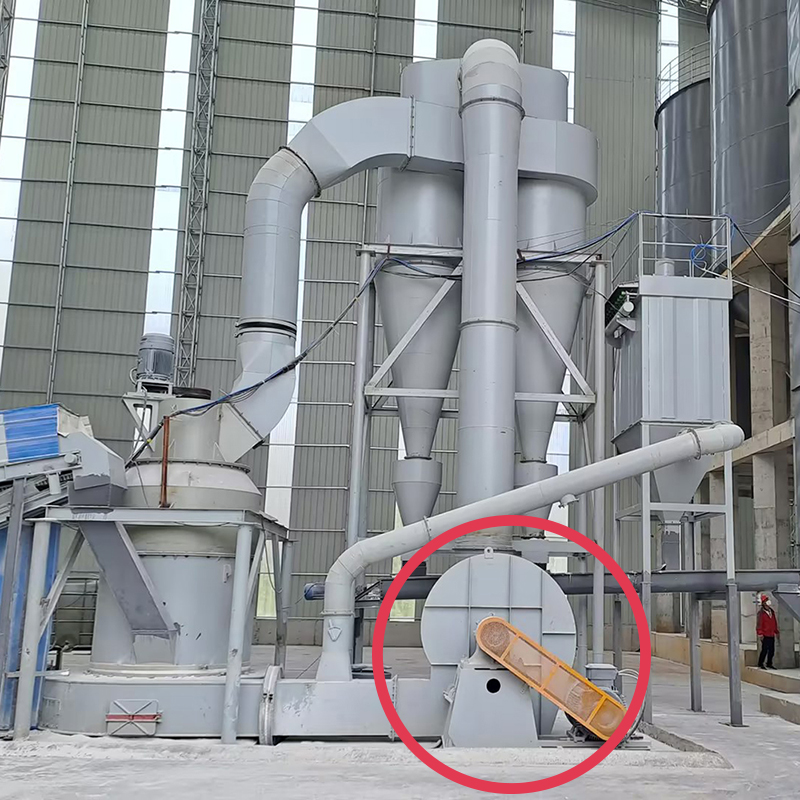

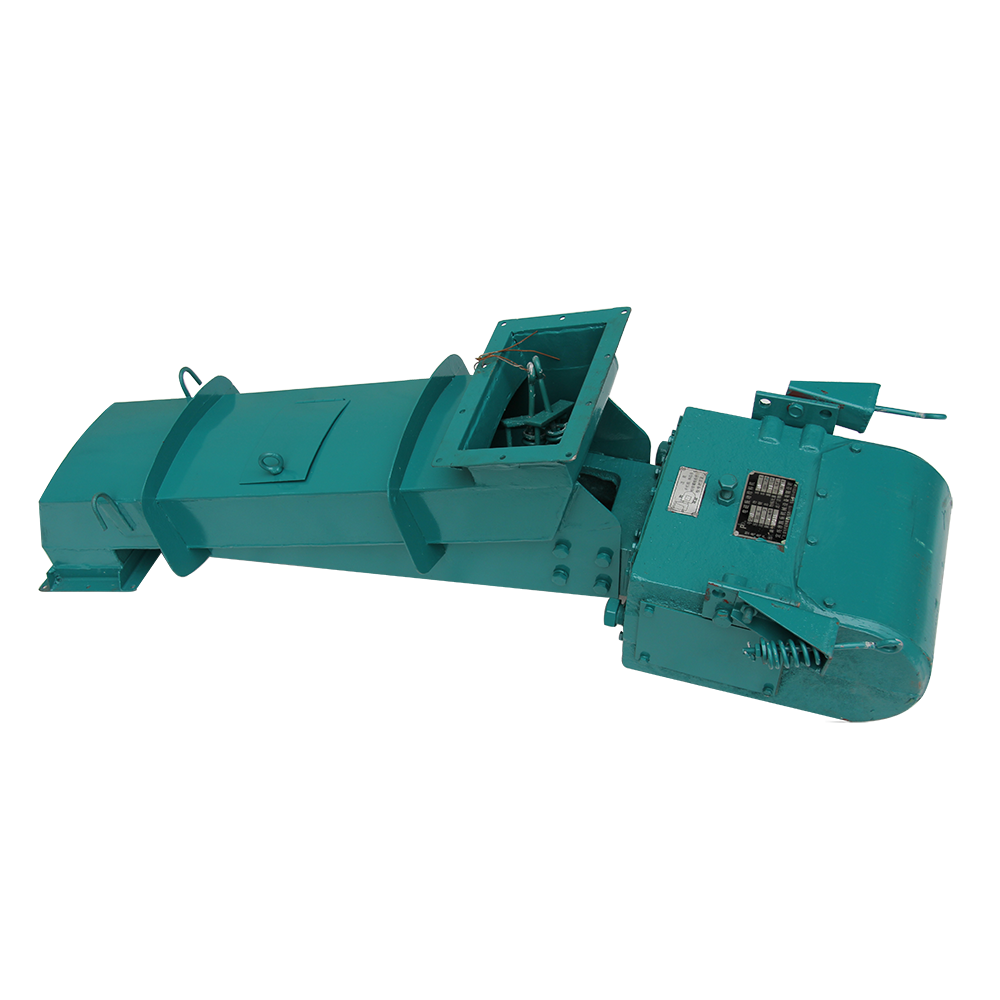

Feeding Equipment: Such as The electromagnetic vibration feeder, it is used to evenly, quantitatively, and continuously feed the materials into the grinding chamber of the main machine for grinding.

Working Principle of Raymond Bowl Mill

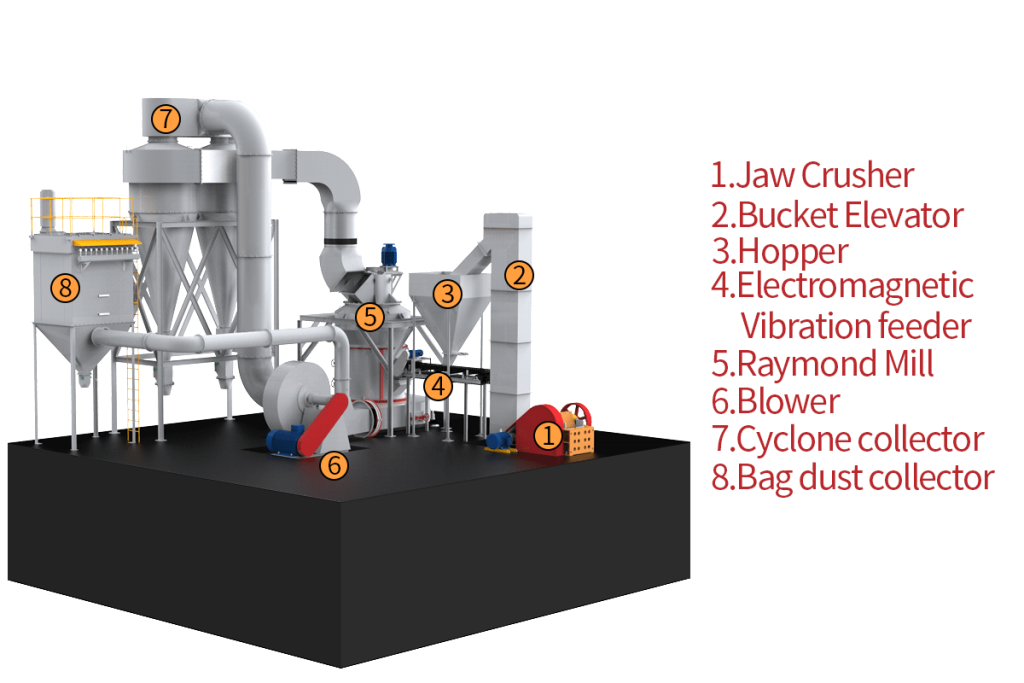

After large – sized materials are crushed to the required particle size by the jaw crusher, they are sent to the storage hopper by the elevator, and then evenly, quantitatively, and continuously sent into the grinding chamber of the main machine by the vibration feeder. Inside the main machine, the grinding roller presses tightly against the grinding ring under the action of centrifugal force. The scraper scoops up the materials and sends them between the grinding roller and the grinding ring, and the materials are crushed into powder under the action of rolling pressure. Then, the powdered materials are blown up by the fan and pass through the analyzing machine. The materials that meet the fineness requirements pass through the analyzing machine, while those that do not meet the requirements return to the grinding chamber for further grinding. The materials that pass through the analyzing machine enter the cyclone separator for separation and collection. The exhaust air is separated by industrial filter cloth to form powder in one process.

The application materials of Raymond bowl mill

It is used to grind various ores into powder for subsequent processing and extraction of valuable minerals, such as the grinding of talc, dolomite, gypsum, calcite, carbon black, calcium carbonate, iron ore, copper ore, gold ore, etc.

Advantages of Raymond bowl mill

1.High Efficiency and Energy Saving

Compared with traditional powder grinding equipment, the Raymond mill has higher production efficiency and lower energy consumption. It can grind a large amount of materials into fine powder in a relatively short time, reducing production costs.

2.Uniform Fineness of Finished Products

Through the precise classification of the analyzing machine, the fineness of the finished powder is uniform, and the sieve – passing rate is high, generally reaching 99%. This is an advantage that is difficult for other powder grinding equipment to achieve, and it can meet the requirements of different users for product fineness.

3. Wide Application Range

It can process various non – flammable and non – explosive minerals with a Mohs hardness of less than seven and a moisture content of less than 6%. It is applicable to a wide variety of materials, including various ores, rocks, and minerals.

4. Easy to Operate

The electrical system adopts centralized control, and the powder grinding workshop can basically operate without human intervention. Moreover, the equipment is easy to maintain, reducing labor intensity and maintenance costs.

5. Small Floor Space

The whole machine has a vertical structure with a three – dimensional layout, occupying a small area. It has strong completeness, forming an independent production system from lumps of materials to finished powder, which can effectively save production space.

Raymond bowl mill diagram

Raymond Bowl Mill Maintenance

The maintenance of Raymond bowl mills is crucial for ensuring stable equipment operation, extending service life, and improving production efficiency. The following introduces the key maintenance points of Raymond bowl mills from aspects such as daily maintenance, key component maintenance, and lubrication management:

- Pre-start Inspection: Before starting the Raymond bowl mill, a comprehensive inspection of the equipment is required. Confirm that all components are firmly connected and that there are no loose bolts; check whether there is residual material or foreign objects inside the main machine, and clean them up promptly if any; check whether the rotating components of the analyzing machine, blower, feeder, and other equipment are flexible and free from jams; ensure that the electrical system is correctly wired, the instrument display is normal, and there are no safety hazards such as electric leakage or short circuits; check whether the lubricating oil level in the lubricating oil tank and bearing housing is sufficient and the oil quality is good. If the lubricating oil is deteriorated or the oil level is insufficient, replace or replenish it promptly.

- Operation Monitoring: During the operation of the equipment, operators should closely monitor its running status. Judge whether the equipment load is normal by observing instrument data such as current and voltage. If abnormal current fluctuations or unstable voltage are found, stop the machine immediately to check the cause; listen to the running sounds of various parts of the equipment. Under normal circumstances, the running sound of the equipment is stable and regular. If abnormal friction, impact, or vibration sounds occur, it may be caused by component wear, looseness, or other faults, and immediate shutdown for troubleshooting is required; pay attention to observing whether the particle size and output of the finished product are stable. If the fineness of the finished product does not meet the requirements or the output drops significantly, it may be due to abnormal rotation speed of the analyzing machine, severe wear of the grinding roller and grinding ring, etc., and adjustments or repairs should be carried out promptly.

- Post-shutdown Cleaning: After each shutdown, the residual materials on the surface and inside of the equipment should be cleaned up promptly to prevent material accumulation from affecting the next startup and normal operation of the equipment. When cleaning the inside of the main machine, focus on removing the materials attached to the grinding roller, grinding ring, and scraper to avoid material caking from affecting the grinding effect; clean the cyclone separator, pipes, and other parts to prevent material blockage and ensure smooth ventilation; regularly clean the dust inside the electrical control cabinet to prevent dust accumulation from affecting the normal operation of electrical components and reducing the probability of failures.

Raymond bowl mill spare parts

Cronus offers you a variety of Raymond bowl mills, including spare parts for Raymond 312a bowl mill, 4R3220 Raymond bowl mill, 1700 Raymond mill, MTW Raymond mill, Raymond 312 bowl mill, Raymond 533 bowl mill, Raymond 633 bowl mill, and other brands. You can also buy the whole Raymond mill production line from Shanghai Cronus. All of our machines are with CE, ISO9001 certification.