Contents Catalog

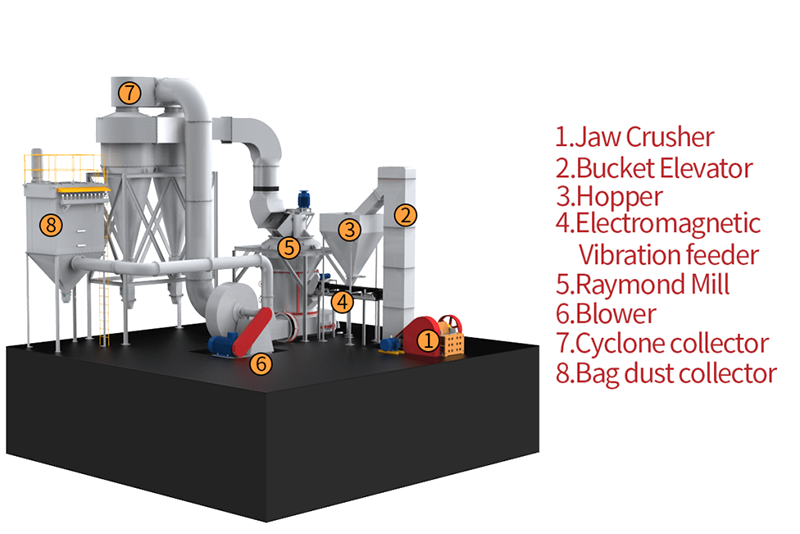

Raymond mill is the basic equipment for grinding. It appeared earlier, has stable performance, affordable price, and the finished product particle size can be adjusted between 80-325 meshes. The finished powder is fine and widely used in the market.

Raymond mill is widely used for processing various non-flammable and non-explosive materials with a Mohs hardness below 9.3, such as more than 280 kinds of materials such as commonly used barite, calcite, talc, limestone, etc.

Advantages of Raymond Mill

Low price

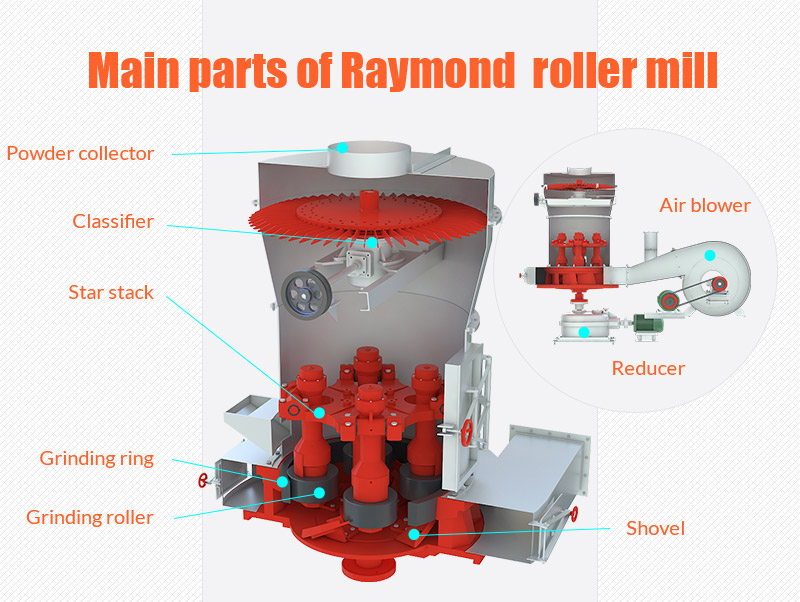

Adopting the advanced structure of similar products at home and abroad, and updating and improving the design on the basis of traditional Raymond mill, compared with similar grinding equipment ball mill, it has high efficiency, low power consumption, small footprint, low price, and can greatly reduce the user’s one-time investment.

Reliable operation

The main engine transmission device adopts sealed gearbox and pulley, with stable transmission and reliable operation

High screening rate

Compared with other grinding equipment, the screening rate is high, up to 99%, which is generally unattainable by other grinding equipment, greatly improving its operating efficiency.

Long service life of wearing parts

The wearing parts are made of high manganese steel with long service life. The motors are all national standard products. The number of maintenance can be reduced in the later use process, the replacement frequency of wearing parts can be reduced, and the use cost can be reduced.

Comply with environmental standards

The main pollution sources of Raymond mills are the leakage of powder and noise pollution during operation. Cronus is equipped with a pulse dust collector and high-quality wear-resistant powder tube to ensure that the machine is leak-free during long-term use.

The overlapping multi-stage sealing mode makes the machine more in line with environmental dust removal standards; it uses low-noise and low-speed centrifugal fans, and air compressors are preferably screw compressors. The design layout is more reasonable, which reduces noise to a greater extent and meets environmental standards as a whole.

What is the market price of large, medium and small Raymond mills?

There are many Raymond mill manufacturers on the market. Each manufacturer has different brands, models, quality, workmanship, and pricing. Generally, the equipment of big brands is of good quality and the price will be slightly higher, but the price is also fair and not outrageously expensive. Moreover, the quality is guaranteed, the after-sales service is more timely, and the later use saves money and worry. In comparison, the cost performance is still very high. Don’t buy inferior equipment for cheapness. In the later use, it will be repaired and stopped every few days, which is not only expensive, but also delays the construction period.

Cronus’s Raymond mill adopts advanced manufacturing technology and high-quality materials, and its wear resistance and stability far exceed the industry standards. Cronus also provides perfect after-sales service. From installation and commissioning to later maintenance, there are professional teams to follow up throughout the process to ensure that customers have no worries in production. Many users have reported that Cronus’s equipment is not only efficient, but also has a very low failure rate. The overall cost is lower after long-term use, which is a truly cost-effective choice.

According to the survey, the market price of large, medium and small Raymond mills on the market is about 150,000 to 900,000 yuan. The larger the model, the higher the output, and the more expensive the price. You can choose the appropriate model according to your own needs, and then select several reliable manufacturers for quotation. After comparison, choose the manufacturer’s equipment with high cost performance.