As the core equipment for limestone deep processing, Raymond Mill plays a key role in the crushing process. After the limestone is initially crushed by the crusher, it needs to be finely ground by the Raymond Mill’s grinding system (including grinding rollers, grinding rings, scrapers and other components).

Application scenarios of limestone

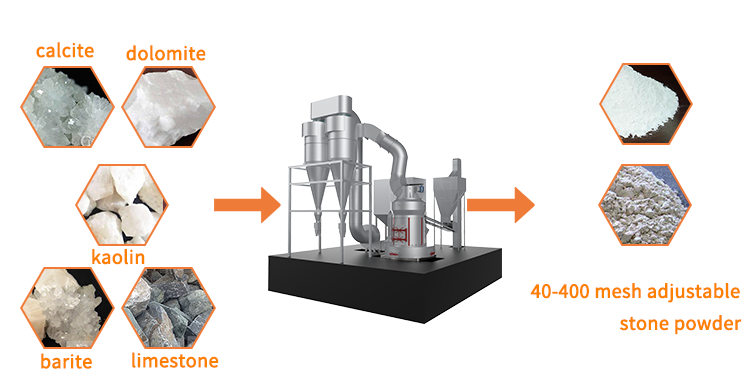

After repeated crushing by crushers, limestone is further processed by Raymond mills and can play an important role in many fields. As the upstream basic raw material for most industrial manufacturing, limestone fine powder covers almost all light and heavy industrial production and manufacturing departments.

Limestone has a wide range of uses. After deep processing by mills of different models and types, limestone can be used to make glass, soda ash, caustic soda and other products.

In the iron-making process, limestone can be used as a flux to remove gangue, while quicklime can be used as a slag-making material to remove harmful impurities such as sulfur and phosphorus. In daily life, limestone can be made into powdered calcium carbonate with high purity after calcination, which is used as a filler in rubber, plastic, paper, toothpaste, cosmetics and other products.

In the agricultural field, quicklime can be used to prepare pesticides such as lime sulfur mixture and Bordeaux mixture; applying slaked lime to the soil can neutralize soil acidity, improve soil structure, and provide plants with the required calcium; brushing tree trunks with lime slurry can protect trees.

The chemical industry can produce important calcium salts such as calcium chloride, calcium nitrate, and calcium sulfite by chemically processing limestone. The cement manufacturing industry is the largest application field of limestone, and the industry is developing rapidly. Cement products have been the main material of construction for 180 years since its invention. There is still no material that can replace limestone in the cement industry. Therefore, investing in a grinding mill production line to process limestone for cement manufacturing is an ideal way to gain economic benefits.

Technical advantages and applications of Raymond mill

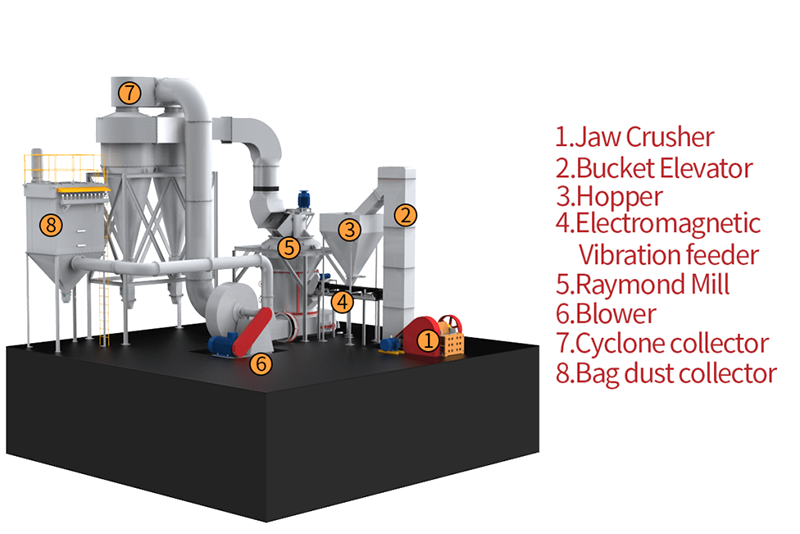

In the process of limestone processing, it is very important to choose a grinding mill with excellent performance. Raymond mill, as the core equipment for deep processing of limestone, occupies a key position in the crushing process. After the limestone is initially crushed by the crusher, it needs to be finely ground with the help of the grinding system of Raymond mill (including grinding rollers, grinding rings, scrapers and other components).

Raymond mill has significant technical advantages:

It has high-efficiency grinding capacity. The centrifugal force generated by the rotation of the grinding roller makes it close to the grinding ring. The crushed limestone particles can be ground into fine powder of 80-325 mesh. Some models can even reach 600 mesh, which can meet the particle size requirements of different industrial scenarios.

It is equipped with an intelligent control system. Through the frequency conversion motor and PLC control system, the feed speed, grinding pressure and discharge fineness can be accurately adjusted to achieve automated production and reduce labor costs.

It adopts low-consumption and environmentally friendly design, equipped with pulse dust collector and silencer, and the dust emission concentration is less than 30mg/m³, which meets the national environmental protection standards. At the same time, the energy consumption is reduced by more than 30% compared with traditional mills.

The limestone fine powder processed by Raymond mill is widely used across multiple industries due to its uniform particle size distribution and high purity. In the cement industry, it serves as a key raw material for clinker calcination, enhancing the strength and stability of the final product. The chemical industry utilizes it to produce high-purity calcium carbonate and calcium hydroxide, essential for applications such as plastic and rubber fillers. In metallurgy, ultra-finely ground limestone acts as an efficient flux in blast furnace ironmaking, effectively removing impurities like sulfur and phosphorus to improve molten iron quality. Additionally, its consistent fineness and chemical composition make it suitable for environmental applications, such as flue gas desulfurization, further expanding its industrial value.

With the technological upgrading of the limestone processing industry, new Raymond mills (such as vertical mills, ultra-fine mills and other improved models) have further improved production capacity (single machine output can reach 5-50 tons per hour) and finished product precision by optimizing grinding paths and material wear resistance, becoming the preferred equipment for cement, chemical and other industries to invest in limestone deep processing production lines.

As a reliable partner in the field of powder processing, Cronus always empowers you with cutting-edge technology, precision manufacturing and full-service. Whether it is fineness adjustment, capacity improvement, or long-term stable operation of equipment, our team will provide you with customized support.

Choose Cronus, choose excellence