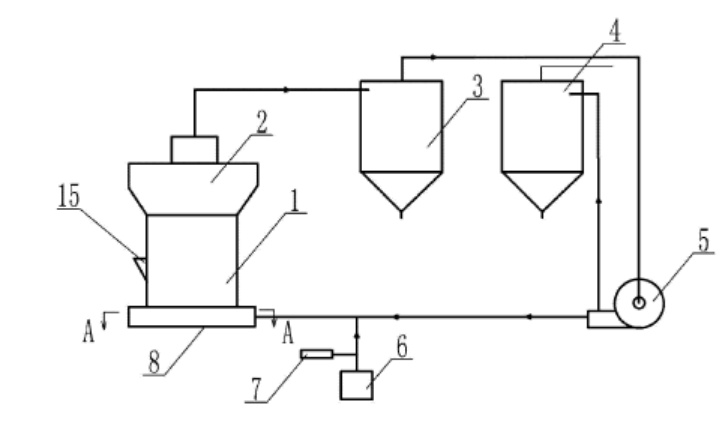

The Raymond mill is the most widely used powder processing equipment in the field, widely used in industries such as metallurgy, building materials, chemicals, and mining. A Raymond mill primarily consists of a main unit, a classifier, a finished product cyclone separator, a fan, a feeder, and piping. The main unit primarily includes the frame, scraper blades, grinding rollers, grinding rings, and a housing.

Working Principle of a Raymond Mill

As the grinding rollers rotate about their vertical axis, centrifugal force presses them against the grinding rings. The scraper blades, rotating with the rollers, spread the material on the bottom plate into the space between the rollers and the grinding rings. There, the material is compressed and ground between the rollers and the grinding rings, pulverizing it. The ground powder is lifted by air from the lower air inlet of the Raymond mill main unit. After passing through the grinding chamber and classifier, fine powder reaching a certain particle size is discharged from the outlet above the main unit and into a cyclone collector.

After being collected, it is discharged through the powder outlet as the finished powder. Material that does not meet the required particle size returns to the grinding chamber for further grinding. Grinding materials often contain sand and gravel, especially in mined materials like bentonite, which often contain a higher proportion of sand and gravel. When these materials are fed into the Raymond mill for grinding, they are constantly scooped up by the blades and repeatedly ground between the grinding rollers and grinding rings. Once ground, they become mixed with the finished powder, resulting in a high impurity content in the finished powder. This requires post-processing to remove impurities and improve its purity, which increases processing steps, energy consumption, and production costs.

Some grinding materials also contain impurities with a higher specific gravity and hardness than the main components. Separating these impurities during the grinding process not only improves the purity of the finished product but also allows for other uses, increasing economic benefits and conserving resources.

Furthermore, some materials with high humidity require drying or airing before grinding, which not only takes up a lot of space and energy, but also increases labor intensity.

Raymond mills, which can remove impurities and dehumidify, can significantly reduce the impurity content in the finished powder, improving its purity. They can also be used to grind materials with high humidity. A Raymond mill capable of removing impurities and dehumidifying material consists of a main unit, a classifier, a finished product cyclone separator, a dust removal bin, and a fan. The main unit primarily consists of grinding rollers, grinding rings, scrapers, and air duct plates. The air duct plates are circumferentially fixed to the main unit base, and impurity removal holes are located on the base plate between the air duct plates.

The raw material to be ground is fed into the Raymond mill from the raw material inlet by a feeder and falls onto the main unit base plate. The scrapers, rotating with the grinding rollers, spread the material from the base plate between the grinding rollers and grinding rings. Sand and gravel have a greater specific gravity than the raw material and tend to sink below the raw material. Because the gap between the scrapers and the base plate is typically about 2 cm, some sand and gravel is carried into the gaps between the air duct plates by the scrapers and leaks out of the impurity removal holes as it passes through them. This sand and gravel is not carried back into the grinding chamber by the airflow through the air duct plates to be repeatedly ground by the grinding rollers and grinding rings. This significantly reduces the sand and gravel content in the finished powder, improving product purity. The finished powder does not require post-processing or purification.

Some other materials containing impurities, particularly those with higher specific gravity and hardness, can also be carried into the gaps between the air duct plates by the scraper during the grinding process. These impurities can then escape through the impurity removal holes and be separated. This not only improves the purity of the finished powder, but also allows the separated impurities to be reused, increasing economic efficiency and conserving resources.

The bottom of the main unit is equipped with a steel plate for adjusting the impurity removal holes, bolted to the main unit base. The plate is easily removable. To seal the impurity removal holes, the plate is bolted to the main unit base. To activate the impurity removal function, simply loosen the bolts and remove the plate.

The bottom of the main unit is equipped with a spiral sand guide, with its sand inlet located below the impurity removal holes. Sand and gravel that escape through the impurity removal holes fall into the inlet of the spiral sand guide and are carried out of the device by the spiral rotation of the spiral sand guide. Installing a spiral sand guide device can reduce the height of the pit beneath the Raymond mainframe, effectively utilizing the pit’s capacity and facilitating the collection of sand and gravel.

To facilitate sand and gravel collection, an impurity collection bag can be connected to the spiral sand guide device. When the impurity collection bag is full of sand and gravel, it can be replaced promptly. The impurity collection bag can be a standard plastic bag or nylon bag.

The diameter of the debris removal holes should be neither too large nor too small, preferably 2-10 cm. More preferably, the diameter of the debris removal holes is 5 cm.

The number of debris removal holes is determined based on the properties of the material and processing requirements. Debris removal holes can be installed between each pair of air duct plates, and the number of holes used can be adjusted using a debris removal hole adjustment plate. The number of debris removal holes is preferably four, evenly spaced on the mainframe baseplate between the two air duct plates.

A heating device is installed in the connecting pipe between the fan and the mainframe. The heating device can use electricity, oil, or coal as its heat source. Coal is readily available and inexpensive, so a coal furnace is preferred. The connecting pipe between the fan and the main unit is equipped with a heating device and a heat conversion medium. This allows the airflow from the fan, carrying high heat energy (air temperature can reach 50-200°C), to enter the main unit of the Raymond mill through the gaps in the air duct plate. This not only raises the material temperature, rapidly evaporating moisture and instantly drying the powder, but also maintains a high temperature for the grinding rollers and rings, preventing material from sticking to them and affecting the grinding effect.

The air duct plate is preferably curved. This allows for smooth tangential airflow inlet and minimizes resistance. The internal outlet orientation facilitates material dispersion and reduces clogging.