During the grinding process, a Raymond mill’s feed hopper is prone to clogging due to its small volume.

The Cronus Raymond Mill feed hopper eliminates this clogging problem, enabling automatic feeding, significantly improving mill feeding efficiency and making it suitable for high-volume production.

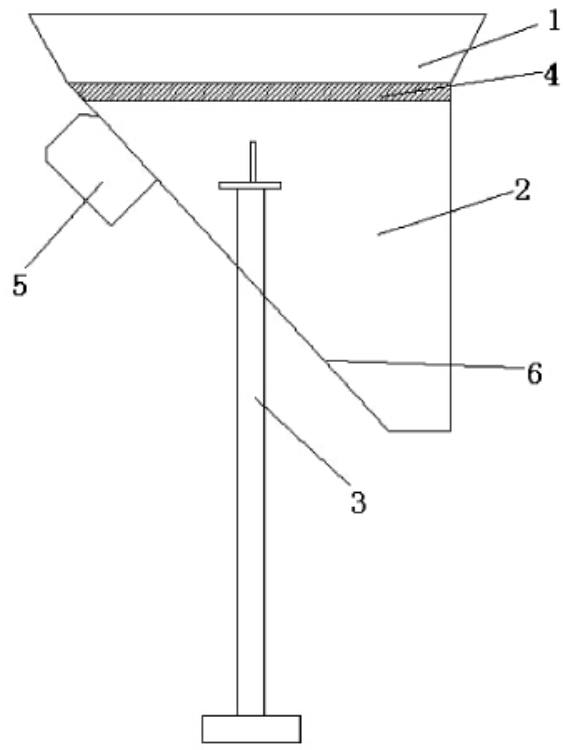

The CRRM Raymond Mill feed hopper consists of a trapezoidal housing, with a right-angled lower hopper connected to its lower end. The lower end of the hopper is supported by a vertical rod. A filter is secured to the upper end of the housing, and a vibrating device is attached to the outer wall of the inclined surface of the lower hopper. The inclined side of the right-angled lower hopper faces the discharge port.

The Raymond mill’s feed hopper consists of a trapezoidal housing 1, connected to a rectangular feed hopper 2 at its lower end. The lower end of the feed hopper 2 is supported by a vertical support 3. A filter 4 is secured to the upper end of the housing 1. A vibrating device 5 is secured to the outer wall of the inclined surface of the feed hopper 2. The inclined edge 6 of the rectangular feed hopper faces the feed inlet.

This structural design effectively prevents material accumulation and blockage at the feed inlet, maintaining a continuous and uniform feed process. Furthermore, the vibrating device ensures smooth material flow into the mill, improving both operational stability and overall production efficiency.