Contents Catalog

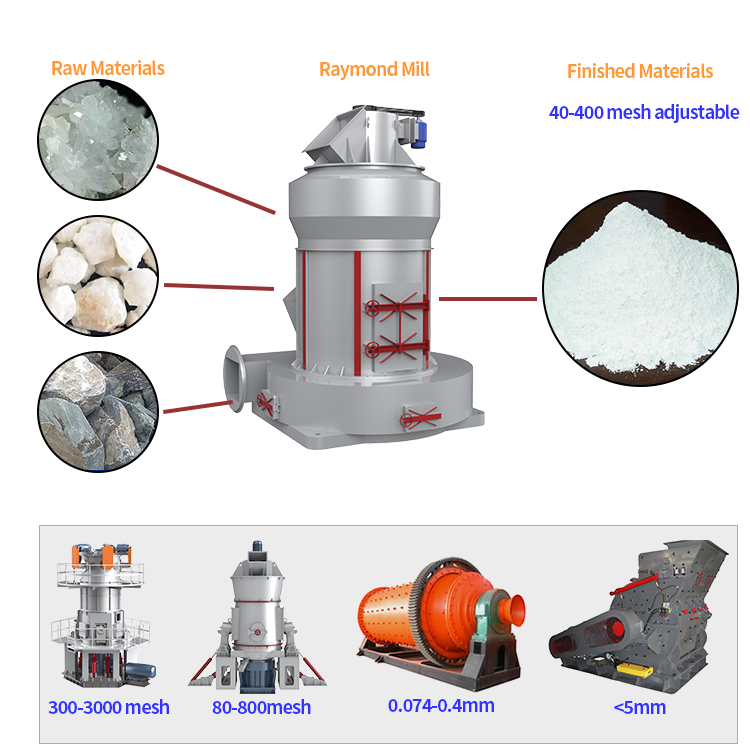

The Raymond mill, also known as a Raymond roller mill, is a highly efficient and environmentally friendly closed-loop grinding system. It combines crushing, particle size classification, and optional drying capabilities to produce finely controlled powder outputs.

The Raymond mill is widely used in cement, chemicals, mining, construction, and metallurgy industries. It is ideal for grinding non-flammable and explosive non-metallic minerals with a Mohs hardness below 7 and a humidity below 6%, such as gypsum, limestone, kaolin, and coal.

The production capacity of the Cronus Raymond mill ranges from 1 to 80 tons per hour, with an adjustable fineness of 80 to 400 mesh.

| Model | Max Feed Size (mm) |

Output Size (mm) |

Dimensions (L×W×H) (mm, without dust collector) |

Capacity (t/h) |

Power (kW) | ||

|---|---|---|---|---|---|---|---|

| Main Unit | Fan | Classifier | |||||

| 4R3220 | 20 | 0.045~0.18 | 6950×4570×8295 | 1~6 | 45 | 45 | 15 |

| CRRM1280 | 20 | 8400×5650×8200 | 1.5~10 | 55 | 55 | 15 | |

| 5R4128 | 20 | 8660×6050×9250 | 2~15 | 90 | 90 | 22 | |

| CRRM1500 | 20 | 8700×5500×9250 | 3~18 | 110 | 110 | 22 | |

| CRRM1620A | 30 | 9670×5570×10550 | 5~22 | 160 | 132 | 30 | |

| CRRM1700 | 30 | 9670×5570×10550 | 6~28 | 185 | 160 | 37 | |

| CRRM1850 | 30 | 10455×6830×9815 | 6.5~30 | 200 | 200 | 37 | |

| CRRM1920 | 30 | 13312×7690×9815 | 7.5~33 | 220 | 220 | 45 | |

| CRRM2150 | 30 | 11080×7600×11150 | 10~40 | 250 | 280 | 45 | |

| CRRM2500 | 35 | 11480×7730×11250 | 11.5~50 | 280 | 280 | 45 | |

| CRRM2750 | 35 | 17000×11000×15000 | 15~80 | 450 | 450 | 75 | |

Raymond mill parts

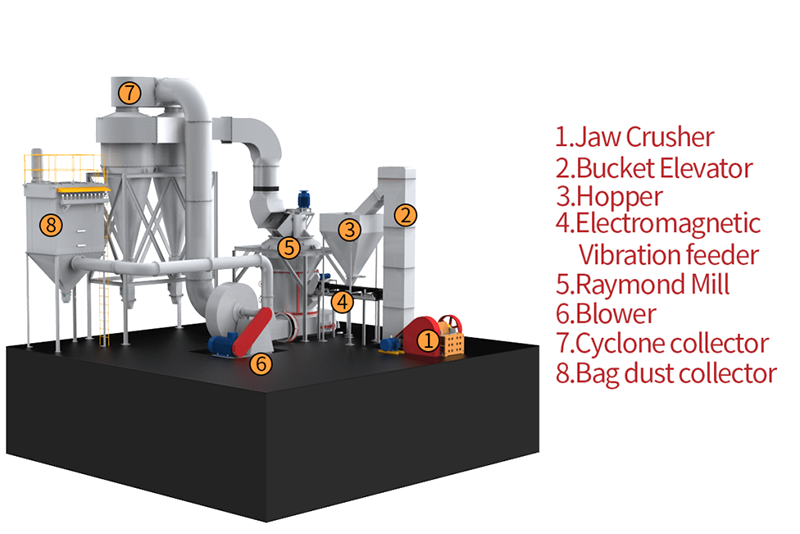

The powder production process of Raymond mill is feeding-crushing-grinding-selecting-collecting, forming an independent production system, among which grinding and collecting are the core links.

Technical features

The main machine adopts a comprehensive shock-absorbing design, with less vibration, low noise, smoother and more reliable operation;

Break through the traditional main machine structure, innovate and optimize the design, energy saving and environmental protection, high overall strength, good rigidity, greatly improve grinding efficiency;

The main machine reducer is a new heavy-duty reducer, which is shock-resistant and wear-resistant, and has good stability;

Use an integral fan, and the fan valve is electric/pneumatically controlled, which makes installation and maintenance more convenient;

Intelligent control: one-button start and stop, arbitrary adjustment, fault alarm.

Raymond mill working principle

Material Preparation

The raw material is crushed into a specified particle size by a jaw crusher, lifted to the hopper by a bucket elevator, and then fed into the mill uniformly and quantitatively by a feeder.

Grinding Process

Inside the mill, the main shaft rotates to generate centrifugal force, causing the grinding roller to swing outward and close to the grinding ring. The rotating shovel scoops up the raw material and throws it between the grinding roller and the grinding ring for grinding.

Classification & Collection

The crushed powder is blown to the classifier by the circulating air of the blower for classification. Under the action of the classifier impeller, the unqualified coarse powder is sent back to the grinding chamber for re-grinding. The qualified powder is collected by the cyclone collector and discharged from the bottom as the final product.

Dust Control

To ensure that the Raymond mill works under negative pressure, the increased airflow enters the pulse dust collector through the pipeline and is discharged into the atmosphere after purification. The dust-free operation of the workshop is achieved by the pulse dust collector.