A Raymond mill uses grinding rollers and grinding rings to crush material. Ore enters the main unit of the Raymond roller mill, where it is crushed by the rollers and grinding rings. Therefore, the consumable parts that require replacement are the grinding rollers and grinding rings. The scraper under the main unit is also a consumable part. The scraper constantly stirs the consumable parts entering the main unit, allowing the material to enter the space between the grinding rollers and grinding rings for grinding. After grinding, the finer materials are separated by a fan and an analyzer and then enter the powder collector. Any less fine materials continue to be ground in the main unit. Another consumable part in a Raymond roller mill is the clevis, which is not frequently replaced. Failure is usually due to imbalance in the grinding roller assembly. Over time, this can cause the clevis to twist, leading to deformation.

The main consumable parts of a Raymond roller mill, the grinding rollers and grinding rings, are made of three materials, and different materials can be selected based on the characteristics of the material being processed. The more wear-resistant a material is, the better it is for your application. If the material you’re processing doesn’t inherently cause much wear on the rollers and rings, then any material can be used without replacement. If the material you’re processing has unique characteristics and causes rapid wear on the rollers and rings, it’s recommended to replace them with more wear-resistant manganese 13 material. This material is a type of impact iron, not particularly hard, but rather resilient, making it more wear-resistant. Manganese 13 rollers and rings are therefore suitable for processing hard materials.

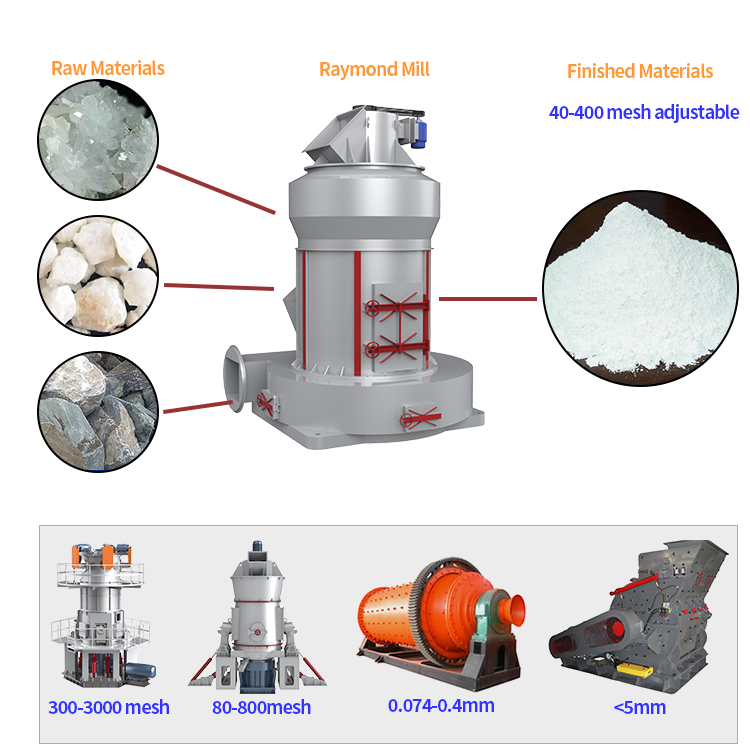

Raymond roller mill process ore materials. The complete system features a sealed structure, with single-feed and single-pulverization, allowing for adjustable fineness. A complete Raymond roller mill system includes over a dozen components, including the main unit, fan, analyzer, dust collector, powder collector, cyclone separator, and piping. After installation, be sure to re-tighten all internal and external screws to prevent loose screws that could affect proper operation.