Contents Catalog

Application scope of the sawdust grinding mill:

It is mainly used for processing materials such as tree branches, wood chips, waste materials, wood boards, and raw bamboo. At the same time, this equipment can also be used for cutting and shredding fibrous stalk-like materials such as bamboo, reed, corn stalks, and sorghum stalks.

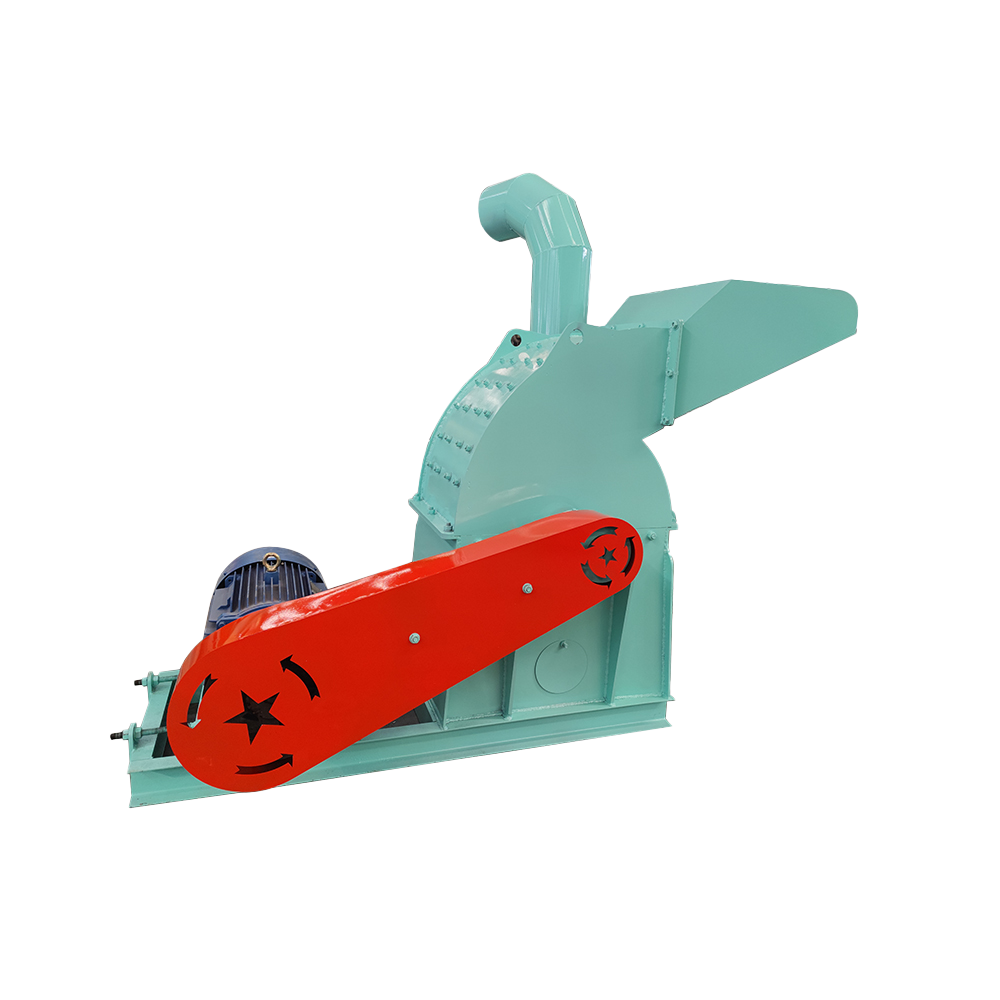

Descripton of sawdust grinding mill

The sawdust pulverizer, also known as the hammer plate pulverizer, is currently a widely used type of pulverizer. It has a high output per unit electricity consumption, good versatility, and in some cases, when metal foreign objects enter the pulverizer, they only break the screen plate without causing major accidents.

However, the particle size of the pulverized material is not uniform and there is a lot of powder. Its structure consists of three parts: the feeding mechanism, the pulverizing chamber (rotor, hammer plate, screen plate, tooth plate), and the discharge part (fan, collecting cylinder, dust collection bag). During operation, the feed enters the pulverizing chamber and is thrown towards the tooth plate under the impact of the high-speed rotating hammer plate.

After colliding with the tooth plate and bouncing back, it is again struck by the hammer plate. At the same time, the feed is subjected to intense friction between the screen surface and the hammer plate. Under the repeated impact, collision and friction, the feed is gradually pulverized. The pulverizer without a fan is made such that the air flow in the pulverizing chamber causes the pulverized material to pass through the sieve holes and be discharged. The pulverizer with a fan extracts the pulverized material from the sieve holes, and then still needs to pass through the dust collection device (such as the collecting cylinder, dust collection bag, etc.) to separate the air from the mixed airflow.

sawdust grinding mill with bag filter

sawdust grinding mill with bag filter

The performance features of the sawdust grinding machine

select the crusher series that matches the hammer tip linear velocity according to the fineness required by the product. If the hammer tip linear velocity is not matched, it will reduce the working efficiency of the crusher and may even cause the crusher to malfunction. A slow linear velocity will result in a long crushing time, causing the material to accumulate in the crushing chamber, leading to screen clogging, reducing the screening efficiency and effect, increasing the resistance to the movement of the hammer tips, and causing the crusher to operate abnormally. An overly fast linear velocity will cause uneven crushing particle size and waste of power consumption.

Select the crusher according to the output required by the scale: The size of the crusher model determines the size of the output, according to the configuration of the crushing process.

The working principle of the sawdust pulverizer

The sawdust crusher adopts the impact crushing method. By using the relative motion between six high – speed rotating movable hammers inside and the fixed toothed ring around, the material is crushed through the impact, friction of the hammer teeth and the impact among the materials themselves. The crushed material, under the action of rotational centrifugal force, passes through the sieve holes and then enters the collection bag.

The operation method of the sawdust grinder

Place it in an appropriate position, ensure it is stable, connect the power supply, and then it can be tried out. Before use, check whether the transmission parts of the machine are loose or have other abnormal phenomena. The direction of the machine’s operation should be consistent with the direction indicated by the arrow. Before use, conduct an no-load test for 1 – 2 minutes. Only when no abnormal phenomena are observed can materials be fed. When feeding, gradually increase the material flow rate, and observe the power consumption and operation of the motor at any time, and feed materials at a constant speed. Before stopping, stop feeding first, and let the machine run for 5 – 20 minutes before stopping to reduce residual materials.

Sawdust working video

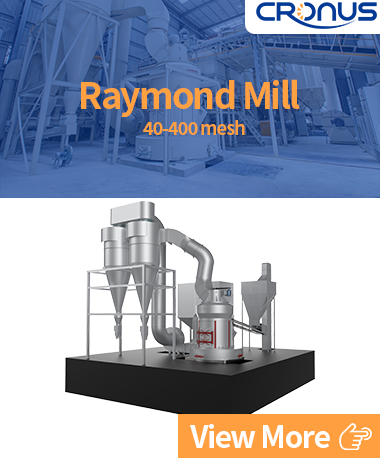

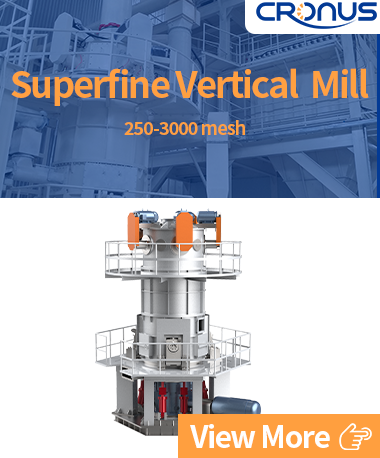

Related Products