Contents Catalog

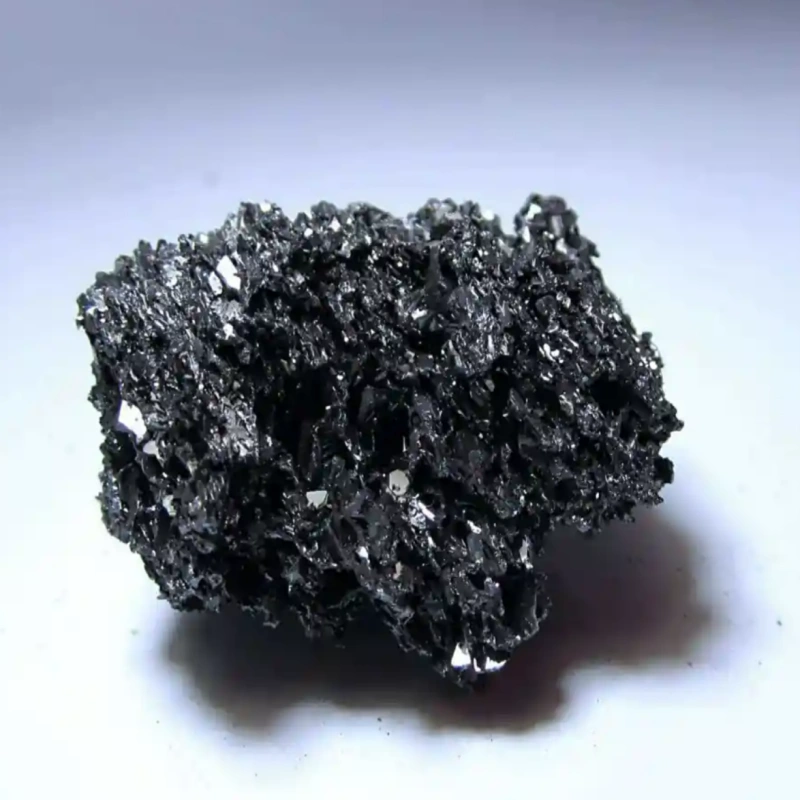

Silicon carbide is an inorganic substance and a semiconductor. It occurs naturally in the extremely rare mineral moissanite. It is now mass-produced in powder and crystal form for use as abrasives, among other applications. Among non-oxide high-tech refractory materials such as C, N, and B, silicon carbide is the most widely used and economical, often referred to as diamond grit or refractory sand.

Specific Applications and Applications of Silicon Carbide

Abrasives and Grinding Tools

Manufacturing abrasive tools: grinding wheels, oilstones, grinding heads, sandpaper, sanding belts, grinding blocks, abrasive pastes, etc.

Precision Machining: Wire Cutting of 3-12 inch single crystal silicon, polycrystalline silicon, potassium arsenide, and quartz crystals; and grinding and polishing for the photovoltaic, semiconductor, and piezoelectric crystal industries.

Metallurgy and Chemical Industry

Metallurgy: Used as a deoxidizer (a new type of strong composite deoxidizer, replacing silicon powder and carbon powder, shortens deoxidation time, improves steel quality, and reduces consumption); improves cast iron structure; and serves as a lining for large blast furnaces (extending service life through corrosion resistance and thermal shock resistance).

Chemical Industry: Used as a raw material for the production of silicon tetrachloride, a major raw material for the silicone resin industry.

High-Temperature and Wear-Resistant Materials

High-Temperature Furnace Components: smelting furnace linings, high-temperature furnace components, silicon carbide plates, liners, supports, saggers, silicon carbide crucibles, etc.

Non-Ferrous Metal Smelting: High-Temperature Indirect Heating Materials (vertical retort furnaces, distillation furnace trays, aluminum electrolysis cells, copper melting furnace linings, etc.); Thermocouple Protection Tubes.

Specialty Industrial Components: Advanced silicon carbide ceramic materials (wear-resistant, corrosion-resistant, and high-temperature resistant); rocket nozzles, gas turbine blades; and materials for highway and aircraft runways. Wear-Resistant Parts: Wear-resistant pipes, impellers, pump chambers, cyclones, and hopper liners (wear resistance 5-20 times that of cast iron and rubber).

Thermal Conductivity and Electronic Materials

Thermal Conductivity Applications: Heat exchangers (can reduce fuel consumption by 20%, save fuel by 35%, and increase productivity by 20-30%); high-temperature resistance, heating, and heat exchange industries (SiC ceramics).

Electronics and Semiconductors: High-purity single crystals can be used to manufacture semiconductors and silicon carbide fibers; used in circuit components, UV detectors, nuclear fuel, and power devices (electric vehicle main drive boards, on-board chargers, power modules, etc.), improving efficiency, increasing battery life, and reducing battery size.

Equipment Overview

The silicon carbide vertical mill (silicon carbide micro-powder mill) is a specialized machine developed and manufactured by Cronus. It integrates crushing and classification, using variable frequency technology to control product particle size, allowing for adjustable fineness and uniform final particle size. This machine is designed and manufactured specifically for crushing high-hardness non-metallic materials. It boasts a rational design, reliable quality, stable performance, simple operation, easy maintenance, and zero dust pollution, making it the optimal equipment for the silicon carbide industry.

Its versatile function allows it to function as a crusher, a standalone classifier, or even a multi-stage cascade system, producing products with 1-3 particle sizes in a single run. It can also be integrated with other crushing equipment in either closed-circuit or open-circuit operation, truly achieving multiple uses in one machine. Furthermore, the machine boasts a compact structure, with all major rotating elements utilizing external systems for easy replacement and maintenance.

Core Advantages of Silicon Carbide Vertical Mill

High Classification Accuracy: A stable and complete classification process and specialized sealing measures reliably prevent the leakage of fine particles. Product sizes range from 500-12,000 mesh, with strict control over oversize.

Low Wear: Grinding components and impellers utilize German technology. Combined with an optimized internal cavity design and wear-resistant, anti-sensitive materials, this minimizes wear and tear on the equipment and maximizes product purity.

Working Principle Silicon Carbide Vertical Mill

When a silicon carbide vertical mill is in operation, the material to be crushed is fed into the mill through a feed hopper on the side of the mill housing. The grinding roller, suspended from the main frame of the micro-powder mill, revolves around a vertical axis while simultaneously rotating. Due to centrifugal force during rotation, the grinding rollers swing outward, pressing against the grinding rings. This causes the scraper blades to scoop up the material and deliver it between the grinding rollers and the grinding rings. The mill achieves its goal of crushing the material through the rolling action of the grinding rollers.

Performance and Features Silicon Carbide Vertical Mill

Long Service Life of Wear Parts

The grinding rollers and grinding rings are forged from special materials, significantly increasing their utilization. For materials and finished product fineness, the wear parts of these mills have a service life 2-5 times longer than those of impact crushers and turbo mills, typically exceeding one year. When processing calcium carbonate and calcite, the service life can reach 2-5 years.

Environmentally Friendly and Clean

A pulse dust collector captures dust, and a muffler reduces noise, making them environmentally friendly and clean.

High Efficiency and Energy Saving

For equivalent finished product fineness and motor power, the output is more than double that of jet mills, stirred mills, and vertical mills.

High Safety and Reliability

Because the mill chamber contains no rolling bearings or screws, there is no risk of bearings and seals becoming easily damaged, nor is there a risk of loose screws causing damage to the machine.

If you have questions about equipment selection, capacity matching, particle size control, or other areas in silicon carbide processing, or would like to learn more about the technical details, application scenarios, and customized solutions for silicon carbide vertical mills, please feel free to contact Cronus.

As a professional team dedicated to the research, development, and manufacturing of silicon carbide vertical mills, Cronus not only provides equipment solutions that combine high precision, stability, and versatility, but also offers comprehensive support from equipment configuration to process optimization tailored to your production needs, helping you efficiently achieve precise processing of silicon carbide powder. Whether it’s initial consultation or ongoing technical support, Cronus will provide professionalism and a comprehensive service system to safeguard your production. We look forward to exploring efficient silicon carbide processing with you.