Contents Catalog

Application of the TH series Bucket elevator

Building materials industry: In the cement production process, it can be used to lift materials such as cement raw materials and clinker, facilitating the transportation of materials during the production stage; in the sand and gravel quarry, it can transport crushed stones and sand to the designated locations, making subsequent processing more convenient.

Chemical industry: It can transport powdered or granular chemical raw materials such as fertilizers and alkali powder. Its stable conveying performance helps ensure the continuity of raw material supply in chemical production.

Food industry: During the process of grain storage and processing, it can lift grains from the ground to storage equipment, or transport raw materials on the processing line to meet the material transportation needs of the food industry.

The working principle of the TH series bucket elevator

The TH series bucket elevator uses forged ring-shaped chains as the traction components. The chains are wound around the upper and lower sprockets. During operation, the bottom hopper will load the materials by extracting, and then move upward along with the rotation of the chains. When it reaches the top position, the materials will be discharged through a mixed or gravity-based unloading method to complete the vertical material transportation.

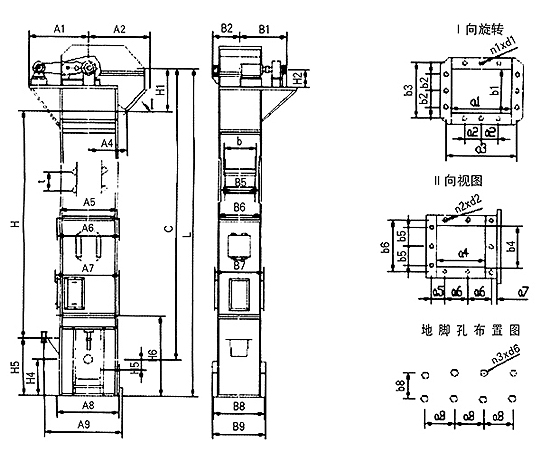

The structural features of the TH series bucket elevator

Chain: A high-round ring chain made of alloy steel, forged and treated with carburizing and quenching process. It shows corresponding performance in terms of tensile strength and wear resistance, which helps to reduce the frequency of equipment maintenance.

Enclosure: The middle part of the enclosure has two designs: single-channel and double-channel. The single-channel is suitable for regular conveying scenarios, while the double-channel can handle situations with larger conveying capacity or the need to convey multiple types of materials simultaneously. The constant force automatic tensioning device in the machine’s heavy hammer box can maintain the chain tensioned state, ensuring the stability of the equipment’s operation.

Sprocket: The sprocket adopts a replaceable rim combination structure. When the rim is worn out, simply unscrew the bolt to remove and replace it. This facilitates maintenance operations and can save some maintenance time.

The equipment performance of the TH series bucket elevator

Conveying capacity: Compared with some other models of bucket elevators with the same bucket width, the TH type bucket elevator has certain advantages in conveying capacity. The improved model also has a corresponding increase in conveying capacity, which can meet the material conveying requirements for some large-scale production.

Operating status: The equipment operates smoothly with minimal noise. The gravity-based automatic tensioning device at the bottom can maintain the tension force, preventing chain slippage or disengagement. When the hopper encounters accidental situations such as jamming, it can also provide certain protection, reducing the probability of equipment failure.

Scope of application: Applicable to the transportation of powdery, granular, and small blocky low-abrasive materials with a bulk density less than 1.5t/m³, such as coal, cement, crushed stones, sand, fertilizers, grains, etc. At the same time, it can transport materials with a temperature not exceeding 250℃. It can be applied in multiple industries.

Technical parameters of the TH bucket elevator

| Model | TH160 | TH200 | TH250 | TH315 | TH400 | TH500 | TH630 | |||||||||||

| Bucket form | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ZH | SH | ||||

| Discharge capacity m³/h | Standard type | 15 | 25 | 18 | 29 | 31 | 48 | 35 | 60 | 60 | 94 | 75 | 118 | 114 | 185 | |||

| Improved version | – | – | – | – | – | – | 46 | 80 | 80 | 125 | 100 | 157 | 152 | 246 | ||||

| Hopper | Hopper width(mm) | 160 | 200 | 250 | 315 | 400 | 500 | 630 | ||||||||||

| Capacity (L) | 1.2 | 1.9 | 1.5 | 2.4 | 3.0 | 4.6 | 3.75 | 6.0 | 5.9 | 9.5 | 9.3 | 15.0 | 14.6 | 23.6 | ||||

| Distance mm | Standard type | 500 | 512 | 688 | ||||||||||||||

| Improved version | – | 384 | 516 | |||||||||||||||

| Chain | Round steel (Diameter×Distance)mm | 14×50 | 18×64 | 22×86 | ||||||||||||||

| Ring | Standard type | 9 | 7 | 7 | ||||||||||||||

| Improved version | – | 5 | 5 | |||||||||||||||

| Conveyor belt operating speed m/s | 1.2 | 1.4 | 1.5 | |||||||||||||||

| Diameter of the main chain wheel’s pitch circle mm | 300 | 365 | 520 | 630 | 710 | 800 | 900 | |||||||||||

| Spindle speed(r/min) | 69.71 | 63.22 | 44.11 | 42.5 | 37.6 | 35.8 | 31.8 | |||||||||||

| materials *mm | 20 | 25 | 30 | 35 | 40 | 50 | 60 | |||||||||||