Cone crushers and impact crushers are both common choices for secondary crushing equipment. However, due to differences in their structure and operating principles, they differ significantly in terms of their application range, output particle size, finished product shape, processing capacity, and investment cost.

In terms of structure and crushing principle, impact crushers use impact force to crush materials. Their design is relatively simple, with materials repeatedly impacting between the hammer and the impact plate, achieving pulverization. Cone crushers, on the other hand, crush materials through extrusion, shearing, and grinding. The mortar and crushing walls continuously move to squeeze and crush the material. Their structure is relatively complex, and their crushing methods are more diverse.

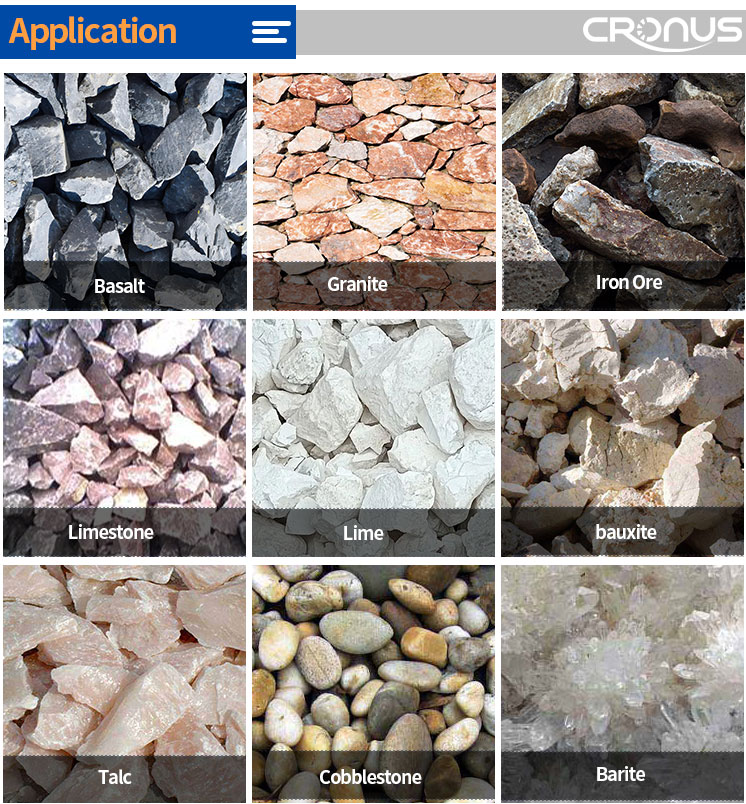

In terms of application, cone crushers are more suitable for processing harder materials such as granite, basalt, tuff, and river pebbles, and are widely used in mining and mineral processing processes. Impact crushers are suitable for crushing softer, more brittle materials such as limestone and limestone, and are therefore more common in the building materials and construction industries.

In terms of discharge performance, cone crushers produce relatively finer material, but the finished product contains more needle-like and flake-like particles. Impact crushers produce higher-quality finished products with fewer sharp edges and more powder, making them suitable for industries with high particle size requirements.

In terms of processing capacity, cone crushers generally offer high output, low energy consumption, and stable operation, making them more suitable for large-scale, high-volume production lines. Impact crushers, on the other hand, are more suitable for small and medium-sized production scenarios.

Comparing costs, impact crushers have lower initial purchase costs, but due to the frequent replacement of wearing parts, ongoing maintenance costs are relatively high. Cone crushers are more expensive, but their wearing parts have a longer lifespan, resulting in lower ongoing operating costs, making them more cost-effective overall.

Furthermore, the two types differ in terms of environmental performance. Impact crushers produce relatively high noise and dust pollution during operation, while cone crushers produce less pollution, better meeting current green production requirements.

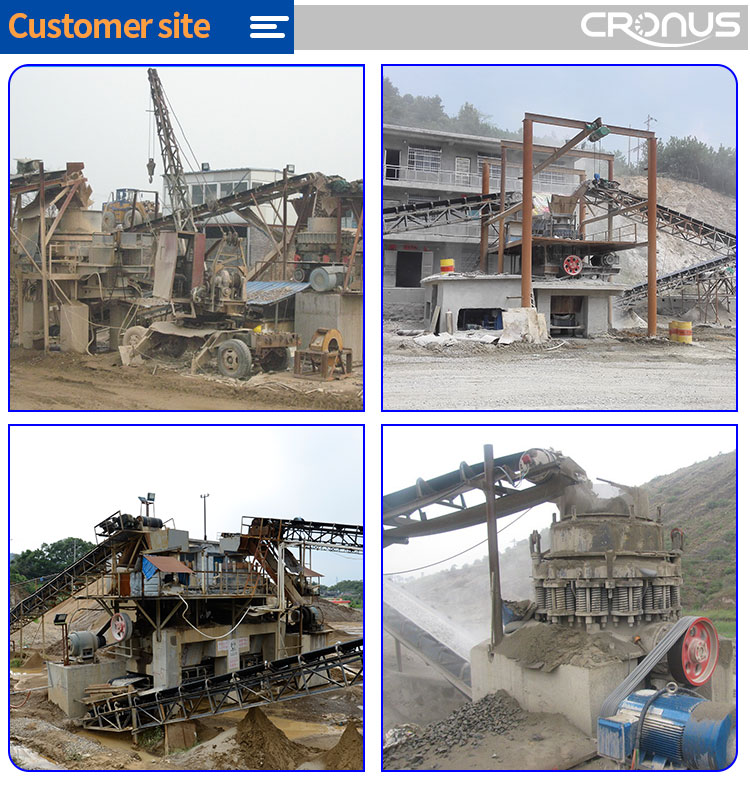

impact crushers and cone crushers each have their own advantages. The specific choice should be based on the hardness of the material, the finished product requirements, the production capacity requirements, and the investment budget. If you need to choose the right secondary crushing equipment for your production line, please contact Shanghai Cronus. We will provide you with professional selection guidance and comprehensive solutions.