Contents Catalog

As ultra fine powder processing becomes increasingly refined and environmentally friendly, Cronus has been deeply involved in the research and development of powder equipment and launched the high-performance CRLMX1200 ultra fine grinding machine. As a new generation of ultra fine grinding machine, this equipment integrates high yield, energy saving, environmental protection, and intelligence. It is widely used in ultra fine processing of non-metallic minerals and is the preferred equipment for the transformation and upgrading of major powder industries.

Technical parameters of Cronus CRLMX1200 Ultra Fine Grinding Machine

| Parameter | Specification |

|---|---|

| Production capacity | 3.8~12 t/h |

| Fineness | 325~1500 mesh |

| Particle size distribution D97 | 10~45±1 |

| Specific surface area | ±1000 cm²/g |

The equipment is widely used in ultrafine grinding of non-metallic minerals such as calcite, marble, limestone, heavy calcium, talc, barite, dolomite, etc., product fineness: 45~8μm (325~1500 mesh), production capacity: between 3.8~12t/h; it can provide high-quality fillers and additives for papermaking, plastics, coatings, rubber, inks, chemicals and other industries. It integrates ultrafine grinding, modification, ultrafine grading and conveying collection. It has the advantages of stable and reliable operation, high grinding efficiency, stable product quality, strong equipment applicability, overall sealing of the system, full negative pressure operation, no dust spillage, convenient maintenance, low operating costs, etc. Its process parameters and performance indicators are close to the international advanced level.

Why choose Cronus’s Ultra Fine Grinding Machine?

✅High efficiency and energy saving, outstanding cost performance

CRLMX1200 adopts a vertical structure. Compared with the traditional ball mill system, it reduces the land area by 50% and the basic investment by about 70%. Under the same production capacity conditions, the power consumption is reduced by 40%~50%, which is the ideal choice for energy saving and cost reduction in the current powder grinding industry.

✅Intelligent control, high product stability

Cronus’s exclusive intelligent hydraulic and grading system realizes dynamic regulation of the grinding roller pressure and powder selection accuracy, ensuring that the ultrafine powder product particle size D97 is accurate, the distribution is concentrated, and the finished product texture is stable and controllable.

✅Integrated system with compact structure

This ultra fine grinding machine integrates the functions of crushing, grading, modification and collection, with a compact layout, easy installation and maintenance, and modular expansion according to process requirements.

✅Environmentally friendly and dust-free operation, in line with green production standards

The equipment adopts a fully enclosed negative pressure operation mode, with no dust spillage, low vibration and low noise. Cronus equips users with an efficient dust removal system (cyclone + bag combination) to fully meet environmental compliance requirements.

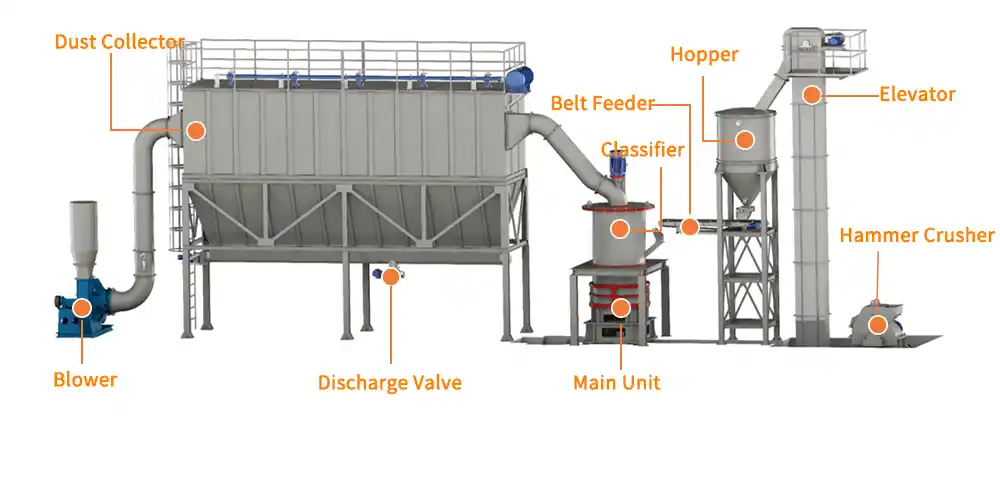

Structural analysis: How does Cronus Ultra Fine Grinding Machine work?

Grinding disc and grinding roller: The core components are made of high-strength wear-resistant materials to ensure long-term stable operation;

Hydraulic system: Accurately adjust the grinding roller pressure to achieve laminated grinding according to the material characteristics;

Efficient classifier: Based on the principle of airflow classification, the fine powder particle size is flexibly controlled by adjusting the speed;

Collection system: Fine powder is recovered by the dust collector, and the exhaust gas is purified and discharged, which is green and environmentally friendly.

Wide application in various industries to meet diverse needs

Cronus’ ultra fine grinding machine has served high-end users in multiple industries:

✅ Calcium carbonate powder: used for high-end coatings, PVC, and papermaking fillers;

✅ Talc and barite: used for rubber, cables, and pharmaceutical excipients;

✅ Dolomite powder: widely used in glass, building materials, ceramics, and other fields;

✅ Functional powder materials: meet the needs of emerging industries such as new energy and battery materials.

Why choose Cronus?

As a technology-based company focusing on the research and development of ultrafine powder equipment, Cronus has strong R&D capabilities and rich industry experience. Our goal is not only to provide an ultra fine grinding machine with excellent performance, but also to help customers create a complete powder solution to achieve the dual goals of product upgrading and cost reduction and efficiency improvement.

Conclusion

If you are looking for an ultra fine grinding solution with stable performance, low energy consumption, and environmental protection standards, Cronus CRLMX1200 ultra fine grinding machine is undoubtedly your best choice. We are committed to providing every customer with professional technical support, reliable equipment quality and continuous after-sales guarantee.

Welcome to contact us for more technical details and application cases, and get customized equipment selection and quotation solutions.