Contents Catalog

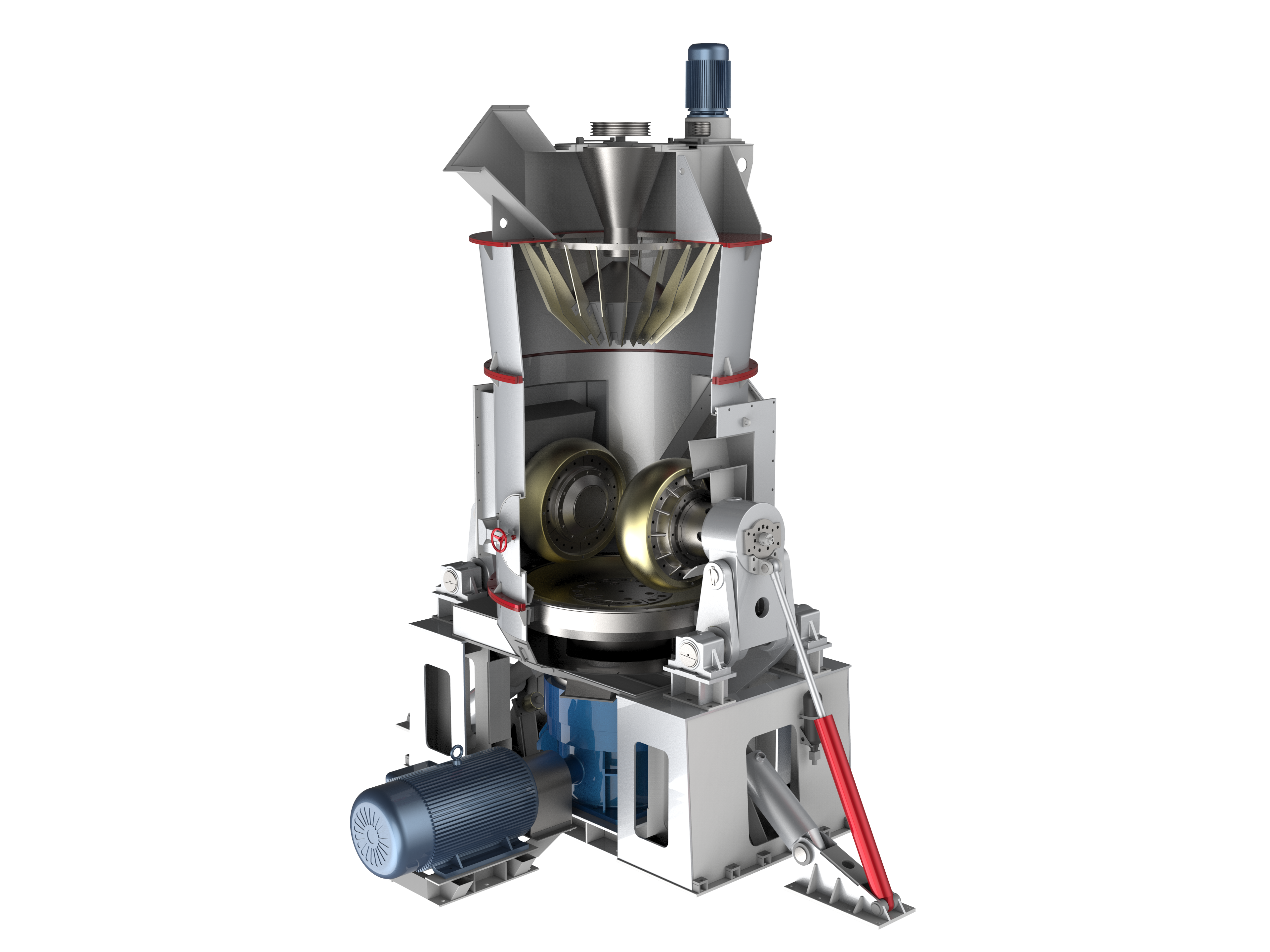

Vertical grinding mills are highly useful equipment that can grind materials into powder while also performing drying, grading, and conveying. They are now widely used in many industries, thanks to their energy efficiency, environmental friendliness, and high efficiency—significantly outperforming older mills. Many industries now prefer them for material processing. Below is an overview of their applications and benefits in sectors such as construction, mining, power generation, and environmental protection.

1. Building Materials Industry

In the construction industry, vertical grinding mills are used to grind materials like cement clinker, limestone, gypsum, and fly ash into powder. The equipment can quickly grind large materials to the required fineness, ensuring the production of high-quality building materials. Compared to older ball mills, they are more energy-efficient, operate more stably, and feature an interconnected system that enables automated, continuous production—helping companies save significant costs.

2. Mining Industry

In ore processing, vertical grinding mills can grind metallic ores, non-metallic ores, and slag into very fine powders. With a small footprint and high grinding speed, they are well-suited to modern mining needs for increased production, reduced energy consumption, and environmentally friendly operations. Additionally, their strong adaptability allows them to process ores of varying hardness and moisture levels, improving beneficiation efficiency and metal recovery rates.

3. Power Industry

Vertical mills are also valuable in thermal power plants and biomass power plants. They finely grind coal to enhance combustion efficiency, control coal particle size, and reduce boiler wear. Moreover, they can process waste materials such as coal ash and slag generated by power plants, enabling their reuse and supporting the development of more eco-friendly power generation systems.

4. Environmental Protection Projects

In environmental projects like municipal sewage treatment, waste incineration, and solid waste disposal, vertical mills process dried sludge and incineration slag by grinding them into fine powder. This simplifies subsequent reuse or safe landfilling of these materials. Their enclosed design and negative pressure operation also prevent dust leakage, ensuring cleaner environmental treatment processes.

5. Other Industries

Beyond the sectors mentioned, vertical mills excel in industries requiring fine processing, including ceramics, glass, chemicals, and pharmaceuticals. For example:

- In the ceramics industry, they grind raw materials like kaolin and feldspar into fine powder.

- In the chemical industry, they process materials such as calcium carbonate and talc.

The fineness of the ground powder can be adjusted to meet the needs of different industries.

Summary

Vertical grinding mills, with their core advantages of multifunctionality, high efficiency, energy saving, environmental protection, and low energy consumption, are continuously expanding their application and becoming a vital support equipment for powder processing in various industries. With technological advancements and increasing environmental protection requirements, vertical grinding mills will play an increasingly critical role in future industrial production. If you have any questions about vertical grinding mill technical specifications, selection guidelines, or specific applications, please feel free to contact our professional engineering team.