Contents Catalog

- 1 What is a vertical Roller mill?

- 2 What are the main components of the vertical Roller mill?

- 3 Main structure:

- 4 Grinding disc:

- 5 Transmission system:

- 6 What are the technical advantages of vertical grinding mills?

- 7 What is the difference between vertical mill vs ball mill vs Raymond mill?

- 8 Parameter comparison table

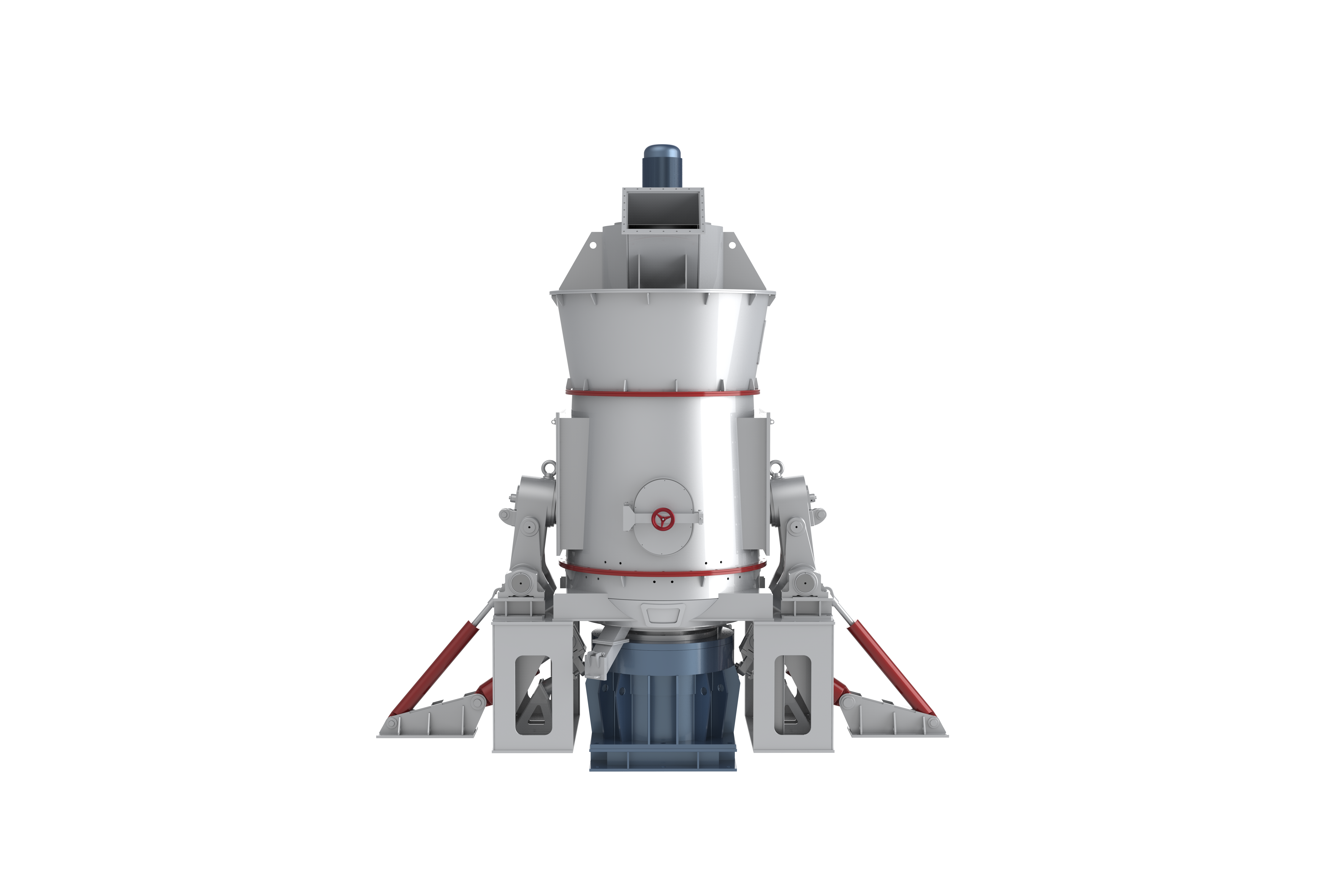

What is a vertical Roller mill?

Vertical Roller mill integrates crushing, drying, grinding, grading and conveying. It is suitable for many industries such as electric power, metallurgy, cement, chemical industry, non-metallic minerals, solid waste treatment, etc. It can process cement raw materials, clinker, slag, steel slag, limestone, coal, gypsum, quartz and other materials.

What are the main components of the vertical Roller mill?

The main structure of the vertical Roller mill includes the body, grinding disc, grinding roller, drive system, feeding system and classification system. Among them, the grinding disc and grinding roller are the most important parts of the vertical mill. They are made of high-strength alloy and can withstand the impact and wear during high-speed rotation.

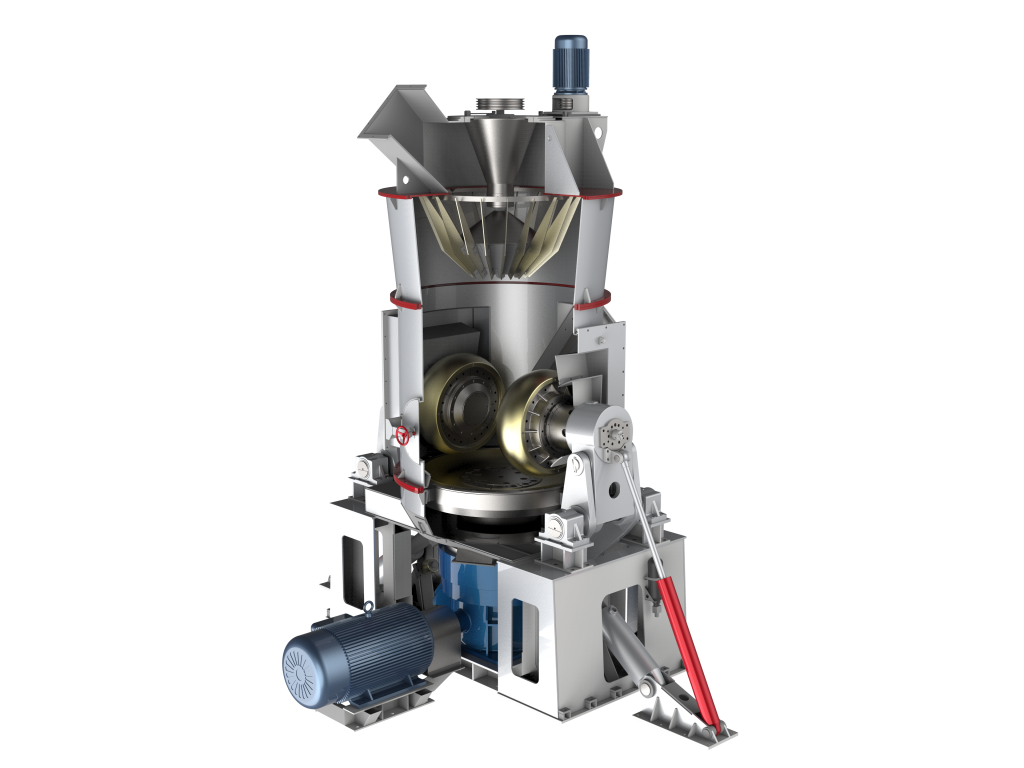

Main structure:

The main structure of the vertical granding mill includes the body, grinding disc, grinding roller, drive system, feeding system and classification system.

Grinding disc:

The grinding disc is the main working part of the vertical granding mill. It is generally composed of a pair of horizontally arranged discs with grinding rollers or grinding balls installed on them. They are made of high-strength alloy and can withstand the impact and wear during high-speed rotation.

Transmission system:

equipped with a transmission system, including a motor, a reducer and a transmission device, which is used to drive the rotation of the grinding disc.

What are the technical advantages of vertical grinding mills?

What is the difference between vertical mill vs ball mill vs Raymond mill?

Parameter comparison table

| Model | CRLM1500K | CRLM1700K | CRLM2000K | CRLM2200K | CRLM2400K | CRLM2800K | CRLM3400K |

|---|---|---|---|---|---|---|---|

| Capacity (t/h) | 6-8 | 10-12 | 15-22 | 25-28 | 24-38 | 45-50 | 60-80 |

| Max. Feed Size (mm) | ≤10 | ||||||

| Slag Moisture (%) | <12 | ||||||

| Product Specific Surface Area (m²/kg) | ≥420 | ||||||

| Product Moisture (%) | ≤1 | ||||||

| Main Motor Power (kW) | 280 | 400 | 500 | 800 | 900 | 1600 | 2400 |

| Note: Material grindability (Bond) index ≤12kwh/t | |||||||