Contents Catalog

- 1 What is a Vertical Roller Mill?

- 2 💡 Why Choose a Vertical Roller Mill?

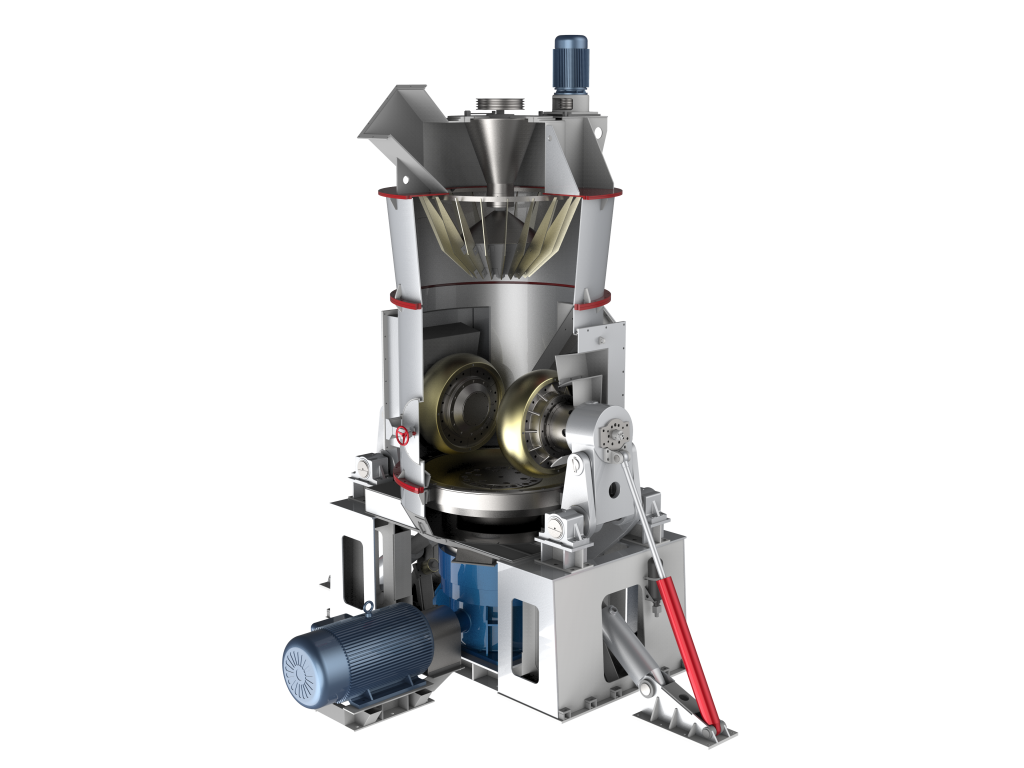

- 3 🛠️ Working Principle of Vertical Roller Mill

- 4 Vertical Roller Mill Technical Parameters

- 5 How Vertical Roller Mill Price Compares Globally

- 6 Basic technical parameters of vertical roller mill

- 7 Get a Custom Quote for a Vertical Roller Mill

Vertical roller mill price is a key consideration for businesses in cement, metallurgy, chemical, and mining industries. Cronus offers an advanced vertical roller mill with independent intellectual property rights, developed through years of technical innovation and international experience. This guide explains the features, benefits, working principle, and cost advantages of vertical roller mills—particularly in applications like non-metallic minerals, coal powder, and slag grinding.

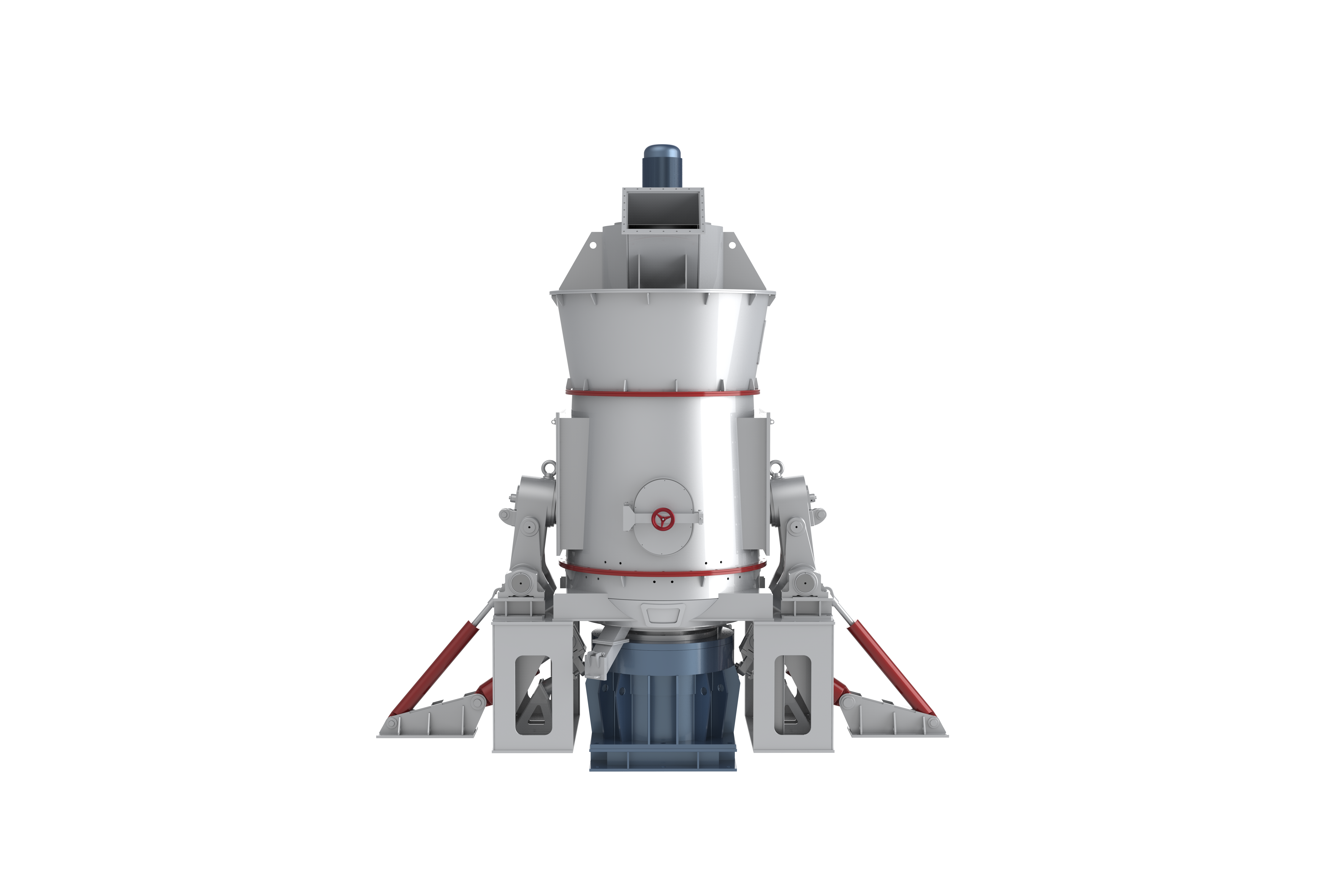

What is a Vertical Roller Mill?

A vertical roller mill is a modern grinding equipment that integrates crushing, drying, grinding, classifying, and conveying into a single system. Designed for efficiency and low operating cost, VRMs are ideal for processing:

💡 Why Choose a Vertical Roller Mill?

🔸 Low Vertical Roller Mill Price = Lower Investment

Thanks to its compact structure and ability to perform multiple processes in one machine, vertical roller mills significantly reduce the need for auxiliary equipment, saving both initial capital and installation space.

- Simple layout, compact design

- Outdoor installation possible

- Low civil construction costs

🔸 Low Operating Costs

Vertical roller mills are energy-efficient due to direct grinding between the roller and the material bed. The use of high-quality wear-resistant materials extends lifespan and minimizes downtime.

- Energy savings compared to ball mills

- Low wear and tear—rollers don’t contact the grinding disc directly

- Long service life of rollers and liners

🔸 High Drying Efficiency

Hot air from an external source enters the mill, contacting the material repeatedly and drying it thoroughly. This makes the VRM suitable for materials with varying moisture content.

- No need for a separate dryer

- Adjustable hot air temperature

- Handles high-moisture materials effectively

🔸 Eco-Friendly and Clean Operation

Operating under negative pressure, the vertical roller mill system is sealed and dust-free, ensuring compliance with modern environmental standards.

- Low vibration and noise

- Dust-free operation

- Complies with national environmental policies

🛠️ Working Principle of Vertical Roller Mill

The vertical roller mill price is justified by its sophisticated yet efficient mechanism:

- Material is fed centrally and moves outward under centrifugal force.

- It gets ground between the grinding rollers and disc surface.

- Fine particles are carried by hot air to the separator.

- Main motor drives the grinding disc via a gearbox.

- Oversized particles return to the grinding zone; qualified fine powder exits the mill.

- Heavier foreign objects fall and are scraped into the slag discharge port.

This closed-loop system ensures consistent product quality and energy efficiency.

Vertical Roller Mill Technical Parameters

| Parameter | Specification |

|---|---|

| Feed Size | 38–65mm |

| Capacity | 13–70 tons/hour |

| Application | Cement, Coal, Slag |

| Focus Industries | Non-metallic minerals, Power, Metallurgy |

How Vertical Roller Mill Price Compares Globally

Compared to traditional ball mills and imported models, the vertical roller mill price from Cronus is highly competitive. It offers:

- Comparable performance

- Lower total cost of ownership

- Local after-sales support

- Custom configurations for specific industries

Basic technical parameters of vertical roller mill

| Specifications | CRLM1300 | CRLM1500 | CRLM1700 | CRLM1900 | CRLM2200 | CRLM2400 | CRLM2800 | CRLM3400 | CRLM3700 |

|---|---|---|---|---|---|---|---|---|---|

| Processing capacity (t/h) | 10-40 | 13-50 | 18-70 | 23-85 | 36-135 | 41-164 | 50-196 | 70-260 | 90-320 |

| Finished product fineness (μm) | 840-33 | 840-33 | 840-33 | 840-33 | 840-33 | 840-33 | 840-33 | 840-33 | 840-33 |

| Mesh | 20-425 | 20-425 | 20-425 | 20-425 | 20-425 | 20-425 | 20-425 | 20-425 | 20-425 |

| Finished product moisture | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% | ≤1% |

| Grinding material size (mm) | <38 | <40 | <42 | <45 | <50 | <55 | <58 | <62 | <65 |

| Optimum grinding material moisture | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% | <4% |

| Grinding material moisture to be dried | <15% | <15% | <15% | <15% | <15% | <15% | <15% | <15% | <15% |

| Grinding air temperature (℃) | <350 | <350 | <350 | <350 | <350 | <350 | <350 | <350 | <350 |

| Grinding air temperature (℃) | 70-95 | 70-95 | 70-95 | 70-95 | 70-95 | 70-95 | 70-95 | 70-95 | 70-95 |

| Main motor power (kW) | 200 | 280 | 400 | 500 | 800 | 900 | 1250 | 1800 | 2500 |

Get a Custom Quote for a Vertical Roller Mill

If you are evaluating vertical roller mill prices for your project, Cronus can provide a custom quote based on material type, capacity and processing requirements.