Contents Catalog

I. What is heavy calcium Carbonate?

Heavy calcium carbonate, abbreviated as heavy calcium, is a powder product made from natural carbonate minerals (such as calcite, marble, limestone, chalk or shells) through mechanical crushing and grinding. It is a very important inorganic powder filler and is widely used in many industrial fields.

Heavy calcium carbonate is highly favored because of its series of excellent physical and chemical properties:

Stable chemical properties: High chemical purity, great inertness, not prone to chemical reactions, and good thermal stability (does not decompose below 400℃).

Excellent physical properties: high whiteness, soft texture, low hardness (Mohs hardness about 3), small abrasion value, dry without crystalline water, low refractive index.

Excellent processing performance: low oil absorption value and good dispersibility.

Safety and environmental protection: Non-toxic, odorless, tasteless and non-irritating.

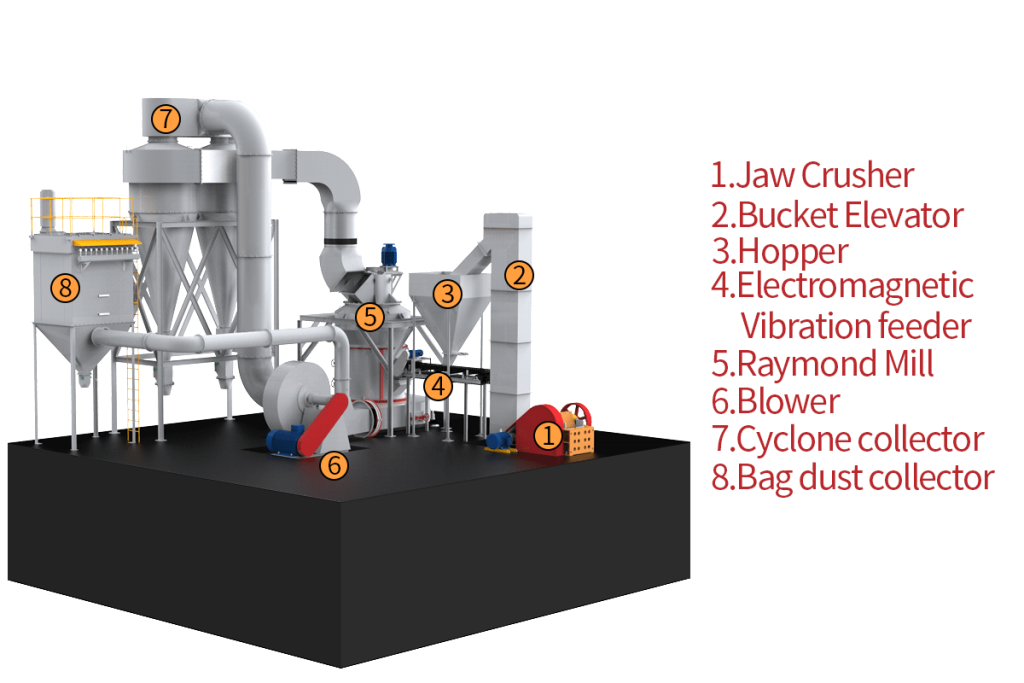

Processing flow of heavy calcium carbonate

First, select calcite, limestone, chalk, shells and other materials transported from the quarry to remove gangue. Then, the limestone is roughly crushed by a crusher, and then ground by a CRRM Raymond mill to obtain fine limestone powder, with a fineness of 80 to 325 mesh and a production capacity of 1 to 80 tons per hour. Finally, the ground powder is classified by a classifier. The powder that meets the particle size requirements is packaged and stored as a product, while the rest is returned to the grinding mill for re-grinding.

II. What are the main uses of heavy calcium carbonate?

With its unique properties, heavy calcium carbonate, as a functional filler and a key raw material for cost reduction, has permeated all aspects of industrial production:

| Application Field | Primary Function | Key Benefits |

|---|---|---|

| Rubber Industry | High-volume filler | Increases product volume and reduces cost; enhances tensile strength, tear strength, and wear resistance of rubber products. |

| Plastics Industry | Skeleton filler | Improves dimensional stability, hardness, and surface gloss of products; high whiteness allows partial replacement of expensive white pigments, reducing costs. |

| Coatings & Paints Industry | Functional filler | Paints: Modifies viscosity and leveling. Water-based Coatings/Latex Paints: Prevents settling, improves dispersion, and enhances film gloss and smoothness. |

| Paper Industry | Filling agent | Fills voids between paper fibers, significantly reducing production costs while maintaining paper strength, whiteness, and opacity. |

| Building Materials Industry | Multi-functional filler | Dry-mix Mortar/Concrete: Improves workability, enhances toughness and strength, controls costs. Artificial Marble/Floor Tiles: Increases whiteness, brightness, and product toughness. Fireproof Ceilings: Enhances whiteness, brightness, and fire performance. |

Conclusion

Heavy calcium carbonate, as a basic industrial raw material, has become an indispensable “industrial rice” in modern industrial production due to its wide availability, low cost and excellent performance. Its application fields are still constantly expanding and deepening.