Contents Catalog

What is Raymond mill?

The Raymond grinding machine is a grinding equipment used in the mining industry. It can process a wide range of materials, including calcite, limestone, talc, talcstone, gypsum, carbon black, wollastonite, dolomite, granite, pumice, zeolite, fluorite, etc., totaling over 100 types of materials. The fineness of the mineral powder processed by this equipment can reach up to 400 mesh, and currently, through the use of improved classifiers in China, the fineness of the fine powder can also be increased to 1000 mesh. Specifically, the appropriate Raymond grinding product should be selected according to different application scenarios.

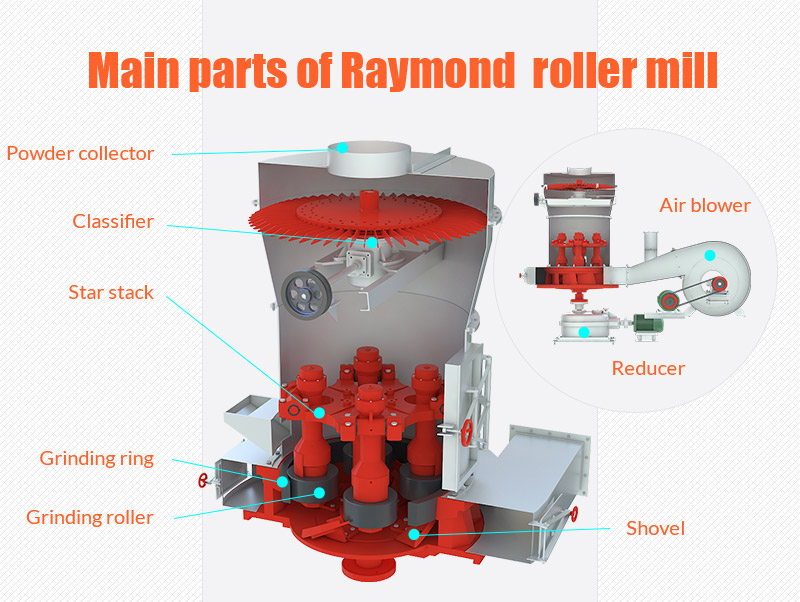

As shown in the picture, what you see is the main body of the Raymond mill. The entire Raymond mill production line is a complete system. It should also include jaw crushers, screw conveyors, silos, fans, the Raymond mill main body, bag dust collectors, as well as packaging machines and palletizing machines, etc.

How does the Raymond mill machine work?

- Grinding Mechanism:

Materials are fed into the mill and crushed between rotating rollers and a stationary grinding ring. The rollers, mounted on a central shaft, orbit the ring while spinning under centrifugal force, creating high-pressure contact that pulverizes the material 15. - Air Classifying:

After grinding, an analyzer (a rotating impeller) separates particles by size. Coarse particles are recycled for regrinding, while fine powders are collected via cyclones or filters. - Circulating Air System:

Air circulates through the mill to cool the process, transport materials, and maintain optimal humidity

What are the various models of Raymond mills? And how are they named?

The Raymond mill can generally be called 3R Raymond mill, 4R Raymond mill and 5R Raymond mill based on the number of rollers. Besides, many companies name their mills according to the diameter and height of the rollers. For example, the 4121 model Raymond mill usually refers to a roller with a diameter of 410mm and a height of 210mm. We often see naming patterns like YGM7815, YGM4121, YGM9517, etc. Some enterprises name their mills based on the diameter of the grinding ring, such as GK1300, GK1280, GK2150, etc. CRONUS adopts this naming method.

What is the difference between Raymond mill and ultrafine mill?

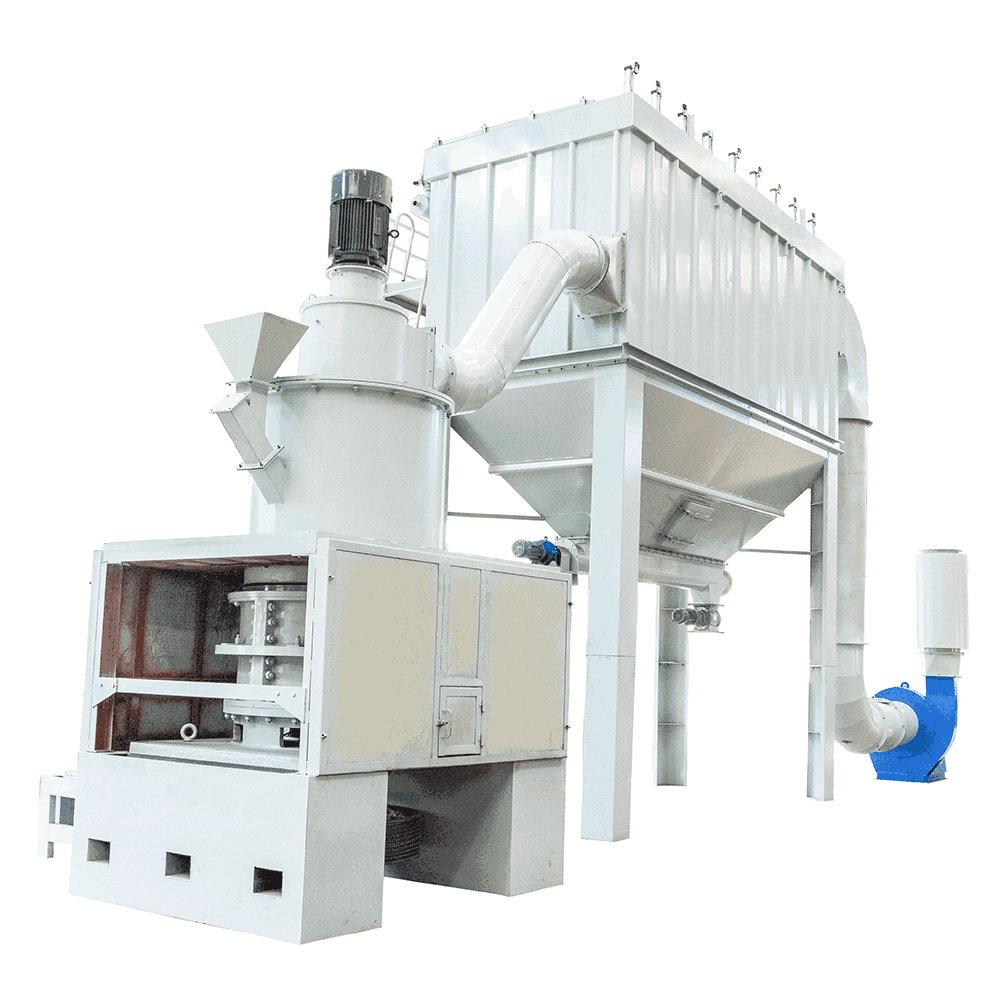

The ultra-fine grinding machine we usually refer to is also called ring roller grinding mill. It is also applied in the field of mineral powder processing, mainly for processing ultra-fine mineral powder. Generally, this machine can achieve a fineness of up to 3000 mesh (approximately 5 micrometers).

As shown in the figure above, the Raymond mill and the ring roller mill have very different appearances. The main difference lies in the fineness of the processed products. The Raymond mill can adjust the fineness of the finished products between 40-400 mesh, while the ultra-fine grinding machine can adjust the fineness between 300-3000 mesh. The applications of their finished micro-powders are also different.

Let’s take the application of calcium carbonate of different fineness as an example to illustrate the differences between the Raymond mill and the ultrafine mill.

Application of 325 mesh calcium carbonate powder

The 325-mesh calcium carbonate powder is widely used as a versatile filler and reinforcing material across industries. It is particularly valued in paper manufacturing to enhance strength, brightness, and cost-effectiveness. In construction, it serves as a key component in dry-mix mortar and concrete, improving durability and reducing production costs. The powder is also essential in artificial marble production for its high whiteness and purity, ensuring smooth surfaces and structural integrity. Additionally, it finds application in adhesives to optimize viscosity and bonding performance, and in select plastic and coating formulations where moderate particle fineness is required to balance hardness and processability.

Application of 3000 mesh calcium carbonate powder

The 3000-mesh calcium carbonate powder, with its ultra-fine particle size and high purity, is widely applied in industries requiring superior surface finish and mechanical properties. In high-end plastics and rubber, it acts as a premium filler to enhance tensile strength, impact resistance, and surface smoothness while maintaining processability. It is crucial in water-based and solvent-based coatings, improving pigment dispersion, hiding power, and gloss without compromising film flexibility. The powder also excels in advanced ink formulations, ensuring uniform color distribution and printability, and in precision adhesives to optimize viscosity and bonding strength. Additionally, it is used in cosmetics and medical applications where fine texture and purity are essential, such as in dental materials or skin-care products.

What are the differences between Raymond mill and vertical mill?

The vertical grinding machines are divided into coarse powder vertical grinding machines and ultra-fine powder vertical grinding machines. Their main differences are as follows:

The coarse powder vertical mill is mainly used for grinding mineral powders such as slag, sluice gates, cement, fly ash, and manganese ore. From this, it can be concluded that the majority of the materials processed by the coarse powder vertical mill are those with high hardness or high metal content that cannot be processed by Raymond mills or ultrafine mills.

The ultra-fine vertical mill, like the Raymond mill and the ring roller mill, is a piece of equipment used for processing non-metallic minerals. The main difference is that the fineness of the ultra-fine vertical mill can be adjusted from 200 to 3000 mesh, and the content of 2-micron particles in the finished products processed by the ultra-fine vertical mill is very high. Currently, in China, the content of 2-micron particles can reach over 80%.

Raymond mill and ultrafine vertical mill are not comparable. The application fields of the ultrafine vertical mill are more advanced.

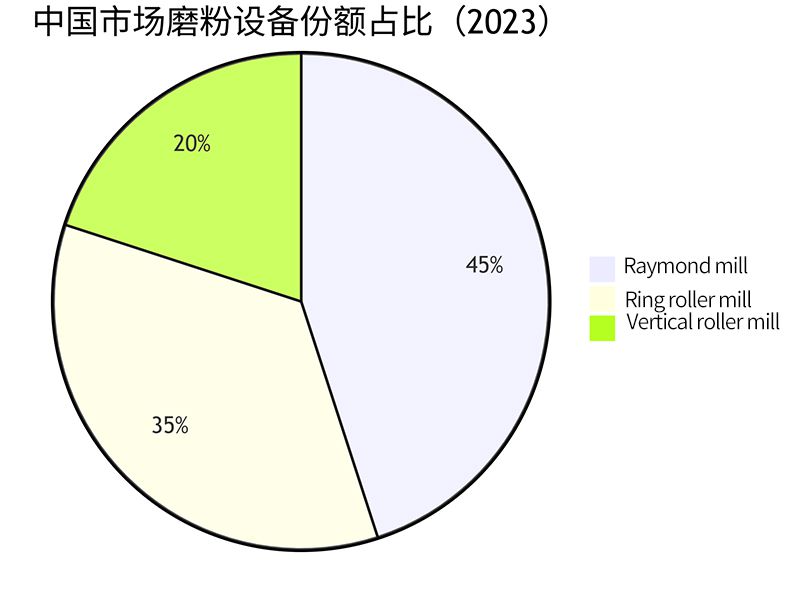

According to the statistics from Deepseek in 2023, the proportions of Raymond mills, ultra-fine grinding machines and ultra-fine vertical mills sold in the Chinese market were 45%, 35% and 20% respectively.