Contents Catalog

A wood chipper, also known as a mushroom material grinder, sawdust grinder, or sawdust machine, is a specialized piece of equipment in the wood crushing series, invented after years of design to meet the needs of China’s industry. It integrates slicing and grinding functions. It can cut branches and tree trunks with a diameter of 1 – 20 centimeters, and can also be used for cutting fibrous stalk-like materials such as bamboo, thatch, corn stalks, and sorghum stalks.

mobile diesel wood chipper

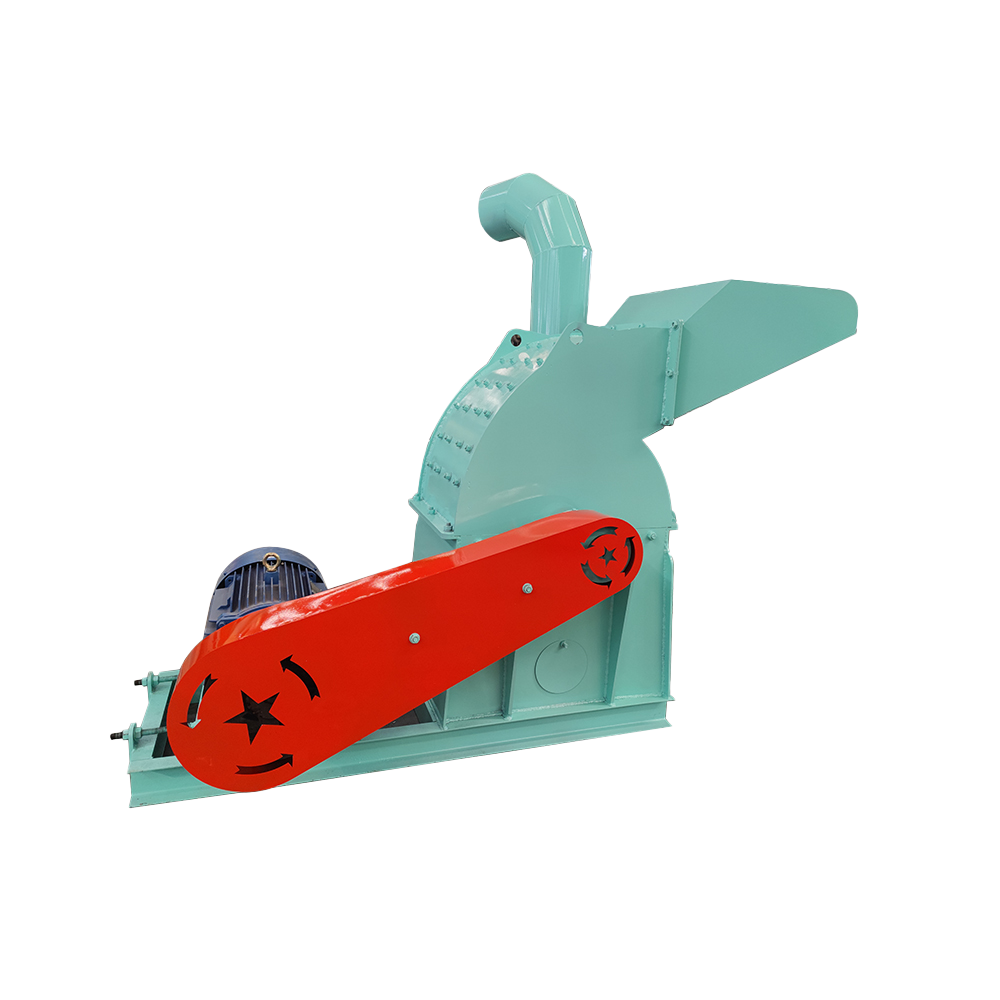

wood chipper

Application of wood chipper

Widely used in mushroom material crushers, various strain material crushers, the preparation sections of industries such as papermaking, edible fungi, machine-made charcoal, particleboard, sawdust board, high-density board, medium-density fiberboard, and single wood powder (sawdust) bases. The raw materials are mainly logs and branches.

Working principle of wood chipper

The wood chipper is a new type of ideal mechanical equipment for the pre-processing of wood powder. It can process raw materials such as wood and branches into wood chips in one go. It has the advantages of low investment, low energy consumption, high efficiency, good economic benefits, and convenient use and maintenance. This wood chipper is especially suitable for the processing of wood chips in the culture medium of edible fungi.

It is mainly composed of a chipping device, a crushing device, and a fan. The wood chips cut by the chipping device have a small particle size and can be sent to the crushing device for further crushing without drying. The finished wood chips after crushing are blown out by the blades on the rotor. The whole set of equipment is driven by only one electric motor, with a simple structure, a compact layout, a low selling price, stable operation, low energy consumption, high output, good quality of the finished wood chips, and low processing costs. It can also be used for cutting fibrous stalk-like materials such as bamboo, thatch, corn stalks, and sorghum stalks. This wood chipper can also be used as raw material for particleboard, sawdust board, and high-density board.

This wood chipper can process pine, miscellaneous wood, poplar, fir, and raw bamboo. Due to its compact structure, small footprint, good chipping quality, low power consumption, and suitability for mobile operations, it is widely applicable to the material preparation section of small and medium-sized particleboard and fiberboard enterprises, and can also be used by individual households for the production of commercial wood chips.

The advantages of the wood chip crusher

1.Adjustment of the Tightness of the V-belt of the Wood Chipper. When the V-belt is too tight, the motor bearing will heat up. When it is too loose, the rotational speed will decrease, and the V-belt is likely to slip. These situations will affect the service life. When adjusting the tension of the V-belt, loosen the bolts fixing the motor base, and use the adjustment bolts to change the position of the motor on the slideway. After the V-belt reaches the required tightness, tighten the fixing bolts.

2.After the wood chipper motor has been operating for a certain period of time, it is necessary to add oil or open and clean the bearings, and then refill with lithium-based lubricating oil to restore the lubricity of the bearings.

3.If the knives of the wood chipper are not of high quality, it is likely to cause situations such as broken knives and waste materials. This situation is generally caused by the inconsistent rotation center of the main shaft of the wood chipper and the center of the knives during the processing, that is, they are not concentric. When the main shaft is running at high speed, if the main shaft and the knives are not concentric, it will not only affect the forming degree of the processed wood chips and the yield of finished products, but also affect the processing effect.

4. The power cord of the wood chipper motor should not be too long or coiled. This can easily cause under-voltage or under-current in the motor. We know that the operating voltage of the motor is 380 volts, and the operating current is marked on the motor nameplate. The rated current of the wire must be greater than the rated current of the motor. Otherwise, the motor is likely to overheat or burn out under conditions of under-voltage or under-current. This is very dangerous for the wood chipper motor.

Technical Parameters of Wood Chipper

| Model | Capacity(TPH) | Power | Weight(kg) | rotate speed | cutter diameter | Blade(alloy steel) |

| 420 | 0.8-1 | 7.5-11KW | 200 | 1500 | 420 | 4 |

| 500 | 1-1.5 | 11-15KW | 320 | 1500 | 500 | 4 |

| 600 | 1.5-2 | 18.5-22KW | 420 | 1500 | 600 | 4 |

| 800 | 3-6 | 22-30kw | 550 | 480 | 800 | 6 |

| 1000 | 5-8 | 45kw | 800 | 550 | 950 | 8 |

| 1100 | 6-9 | 45-55kw | 1650 | 600 | 1100 | 8 |

| 1210 | 8-10 | 75kw | 2100 | 600 | 1210 | 8 |

| 1410 | 10-15 | 90-120kw | 2800 | 600 | 1410 | 8 |

Cronus Machinery Co., Ltd. can customize the production of various types of wood chippers, wood chipper shredders, wood powder grinding machines, and biomass pellet machines. According to the actual needs of customers, mobile and fixed machines can be customized, and they can also be equipped with diesel engines or electric motors as the power source.

Related Products

About sawdust crusher

The sawdust crusher, also known as the hammer mill, is a widely used crusher at present. It has a relatively high output per kilowatt-hour, good versatility. Some hammer pieces are hinged to the rotor. When metal foreign objects enter the crusher, only the sieve plate will be broken, and no major accidents will occur. However, the particle size of the crushed material is uneven, and there is more powder.

Its structure consists of three parts: the feeding mechanism, the crushing chamber (rotor, hammer pieces, sieve plate, tooth plate), and the discharging part (fan, aggregate cylinder, dust collection bag). During operation, the feed enters the crushing chamber from the feeding mechanism, flies towards the tooth plate under the impact of the high-speed rotating hammer pieces, rebounds after colliding with the tooth plate, and is hit by the hammer pieces again. At the same time, the feed also undergoes intense friction between the sieve surface and the hammer pieces.

Under the repeated impacts, collisions, and frictions, the feed is gradually crushed. For crushers without a fan, the crushed material is discharged through the sieve holes by the airflow in the crushing chamber. For crushers with a fan, after the crushed material is drawn out from the sieve holes, it still needs to pass through a powder collection device (such as an aggregate cylinder, dust collection bag, etc.) to separate the air in the mixed airflow from the crushed material.

About Wood Powder Grinding Mill

Wood powder machines are mainly divided into standard wood powder machines, ultra-fine wood powder machines, ordinary wood powder machines, vertical wood powder machines, stainless steel wood powder machines for Chinese herbal medicines, and air-selected wood powder machines. The standard wood powder making machine is another new product of our company in the wood powder machine market. This product can ensure the standard rate of the finished product, solve the inconvenience caused by uneven fineness of the finished product. It is internally equipped with a standard stainless-steel screen, and the mesh number can be selected and standardized arbitrarily. It occupies a small area, is convenient for packaging, easy to operate, and has absolutely no dust pollution. It is an ideal powder-making equipment.