Contents Catalog

- 1 What is calcium carbonate Raymond mill?

- 2 The equipment composition of the calcium carbonate Raymond mill

- 3 The working principle of the calcium carbonate Raymond mill

- 4 Technical parameters of the calcium carbonate Raymond mill

- 5 On-site demonstration of the calcium carbonate Raymond mill:

- 6 Application of 325-mesh calcium carbonate powder

- 7 Other calcium carbonate powder equipment

- 8 More About Calcium Carbonate and Cronus

What is calcium carbonate Raymond mill?

The Raymond mill for calcium carbonate is essential equipment used in the production of calcium carbonate powder. The calcium carbonate raw materials that it can process include calcite, limestone, dolomite, marble, etc. It can also be applied to the processing of other mineral powders, such as talc powder, barite powder, pyrophyllite powder, tire pyrolysis carbon black powder, etc.

The fineness of the mineral powder processed by the Raymond mill can reach up to 400 mesh, with an adjustable range from 40 to 400 mesh.

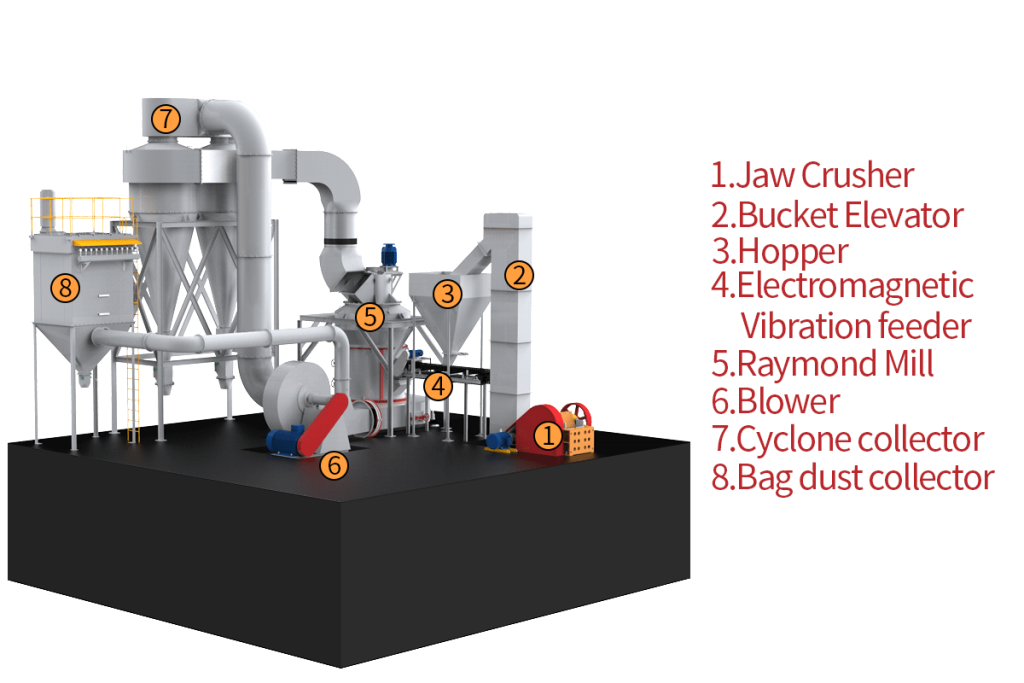

The equipment composition of the calcium carbonate Raymond mill

Calcium carbonate Raymond mill is a complete production line equipment, including the crushing part of the ore, the grinding part, the powder collection system, the dust removal system, and even the subsequent packaging and palletizing system can be configured according to the customer’s requirements.

The working principle of the calcium carbonate Raymond mill

Big materials are crushed by a jaw crusher to the required particle sizes, and carried by a bucket elevator to the storage hopper, and are fed evenly and continuously by a vibrating feeder into the main unit for grinding. The ground powder are carried by the airflow from the blower to the classifier to be classified, the particles that meet the fineness enter the cyclone collector through the pipe, and are separated and collected there. They are discharged at the discharging valve to become finished products; The airflow is sucked to the blower by the return pipe on the top of the cyclone collector. The whole airflow system is a sealed circulation and is circulated under positive and negative air pressure.

Technical parameters of the calcium carbonate Raymond mill

| Model | Feed particle size (mm) | Product granularity (mm) | Overall dimensions (Length * width * height(mm) (Does not include dust collector) | Capacity(t/h) | power(kW) | ||

|---|---|---|---|---|---|---|---|

| Main Machine | Fan | Classifier | |||||

| 4R3220 | 20 | 0.045~0.18 | 6950×4570×8295 | 1~6 | 45 | 45 | 15 |

| CRRM1280 | 20 | 8400×5650×8200 | 1.5~10 | 55 | 55 | 15 | |

| 5R4128 | 20 | 8660×6050×9250 | 2~15 | 90 | 90 | 22 | |

| CRRM1500 | 20 | 8700×5500×9250 | 3~18 | 110 | 110 | 22 | |

| CRRM1620A | 30 | 9670×5570×10550 | 5~22 | 160 | 132 | 30 | |

| CRRM1700 | 30 | 9670×5570×10550 | 6~28 | 185 | 160 | 37 | |

| CRRM1850 | 30 | 10455×6830×9815 | 6.5~30 | 200 | 200 | 37 | |

| CRRM1920 | 30 | 13312×7690×9815 | 7.5~33 | 220 | 200 | 45 | |

| CRRM2150 | 30 | 11080×7600×11150 | 10~40 | 250 | 250 | 45 | |

| CRRM2500 | 35 | 11480×7730×11250 | 11.5~50 | 280 | 280 | 45 | |

On-site demonstration of the calcium carbonate Raymond mill:

Application of 325-mesh calcium carbonate powder

325 mesh calcium carbonate powder is a commonly used inorganic powder material, with its unique physical and chemical properties, it has extensive applications in multiple fields.

In the construction industry, 325 mesh calcium carbonate powder is an important building material additive. When added to cement, it can improve the construction performance of cement, increase the fluidity and plasticity of cement, and also reduce production costs to a certain extent. In dry-mixed mortar, it can play a filling role, improve the strength and durability of the mortar, making the mortar more solid and durable after construction, suitable for wall masonry, plastering and other projects.

The rubber industry also cannot do without 325 mesh calcium carbonate powder. As a filler for rubber products, it can increase the volume of rubber, reduce production costs, and also improve the wear resistance, tear resistance and hardness of rubber. Whether it is tires, rubber seals or rubber hoses, it can be seen that it is present, making rubber products more durable during use.

In the plastic industry, 325 mesh calcium carbonate powder also plays an important role. When added to plastics, it can not only reduce the raw material cost of plastics, but also improve the rigidity, heat resistance and dimensional stability of plastics. For example, adding an appropriate amount of 325 mesh calcium carbonate powder to polypropylene, polyethylene and other plastic products can make plastic products less prone to deformation during use, improve their service life, and be widely used in the production of plastic pipes, plastic films, plastic containers, etc.

In the paint industry, 325 mesh calcium carbonate powder can be used as a body pigment. It can enhance the covering power, adhesion and weather resistance of the paint, making the coating formed after painting more uniform and smooth, and better resisting the erosion of the external environment, prolonging the service life of the paint. Whether it is interior wall paint, exterior wall paint or industrial paint, 325 mesh calcium carbonate powder is often used to optimize the performance of the paint.

In addition, in the paper industry, 325 mesh calcium carbonate powder can be used for paper filling and coating. As a filler, it can improve the whiteness, opacity and smoothness of the paper, improve the printing performance of the paper; as a coating pigment, it can make the surface of the paper more delicate, improve the glossiness and wear resistance of the paper, making the printed text and patterns clearer and more beautiful.