Contents Catalog

Introduction of small superfine powder raymond mill

The small Raymond mill is a smaller grinding equipment. Its weight is only one-third of that of an ordinary mill. It is easier to transport than an ordinary mill and has a lower transportation cost. Its new design and three-dimensional structural model create a more convenient and flexible working method. Therefore, it is favored and welcomed by the chemical, construction, building materials, glass, environmental protection, water conservancy and other fields.

Working principle of small superfine powder raymond mill

The small superfine powder raymond mill mainly relies on the mutual extrusion between the roller and the grinding ring to complete the material grinding operation. When working, the transmission device drives the roller shaft on the plum blossom frame to rotate rapidly, and the grinding ring that acts on the grinding roller is fixed. When the material is fed into the machine body by the feeding device, a scraper is also installed at an angle at the front end of the roller to continuously feed the material into the grinding area between the grinding roller and the grinding ring.

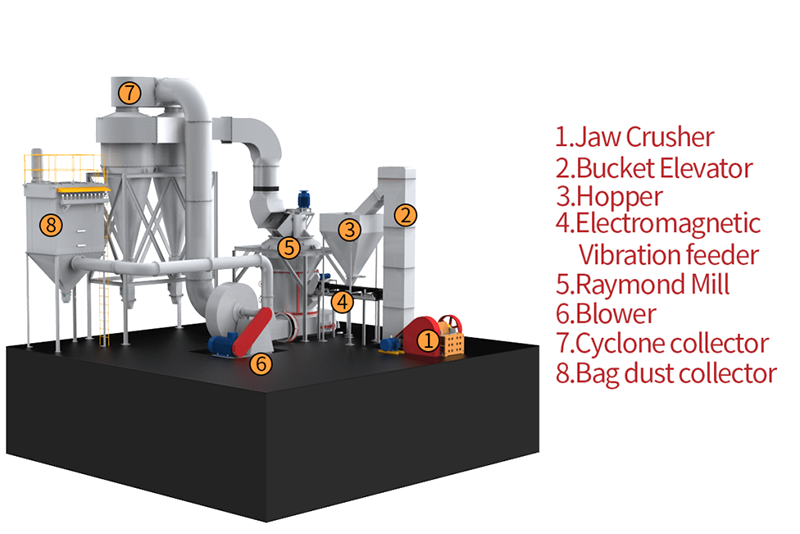

The working process of the mill is generally divided into three aspects:

crushing——grinding —— powder selection.

Detailed workflow

First, the material is crushed to a fineness that can enter the mill, then sent to the hopper by the elevator and then sent to the grinding chamber of the mill for processing through the vibrating feeder. According to the working principle of the mill, it is ground and graded. Unqualified materials are returned to the mill for grinding, and qualified materials enter the cyclone powder collector and then collected and packaged.

Noise problems and solutions

The mill will have some problems after long-term work, such as some noise during the grinding process, which is normal. However, if a relatively loud noise is generated during production, this is not normal. There should be some faults somewhere. So how to solve the problem of excessive noise when the mill is working?

First, check the transmission gear. If the clearance of the transmission gear is too large or too small, there will be a phenomenon of tooth knocking, which will cause the transmission gear to wear quickly, the ruler to deform, the vibration amplitude to be large, and noise to be generated. Therefore, the meshing clearance of the transmission gear of the equipment should be checked and adjusted regularly, and if there is a fault, it should be handled in time.

If the noise is caused by the vibration of the main machine, then you need to check whether the grounding bolt is loose. If it is loose, tighten it immediately; you also need to check the feeding material. If the material is too large or too small, adjust it in time.

If the noise is caused by the vibration of the fan, you need to check whether there is dust on the fan blade, or the fan blade is unevenly worn. When the mill is working, the fan blade is unstable during rotation and causes the fan to vibrate. In general, if the mill is maintained and maintained regularly, the occurrence of such faults can be greatly reduced, thereby improving work efficiency.