Uneven material discharge from the crusher is a common problem in production. If not dealt with promptly, it will disrupt the production schedule. In fact, by finding the right method, it can be quickly resolved. Below, from the perspective of practical operation, we will discuss how to troubleshoot. Prevent the crusher from getting stuck 1. […]

The compound cone crusher is an efficient crushing equipment primarily designed for the fine crushing of medium-hard or harder ores and rocks. Its working principle is based on compressing and crushing material between a fixed cone and a moving cone until the desired particle size is achieved. The design aims to provide high production capacity, […]

The sand-making production line is composed of a series of mechanical equipment, including vibrating feeders, crushers, vibrating screens, conveyor belts, sand washers and sand makers (impact crushers). The function of this production line is to process raw materials such as sandstone, river pebbles, gravel, and basalt into construction and industrial sand through a sand-making machine […]

The cone crusher plays a crucial role in the production line as a medium and fine crusher, and is favored for its high crushing efficiency, large production capacity, and low maintenance cost. Shanghai Cronus’s cone crushers are divided into single-cylinder hydraulic cone crushers and multi-cylinder hydraulic cone crushers. To ensure the stable operation of the […]

One of the most concerned issues for purchasers and operators is the type of stones that the Raymond mill can grind and the requirements. As a commonly used grinding equipment, it can handle a wide variety of materials, but not all stones can be ground. There are clear requirements for the particle size, hardness and […]

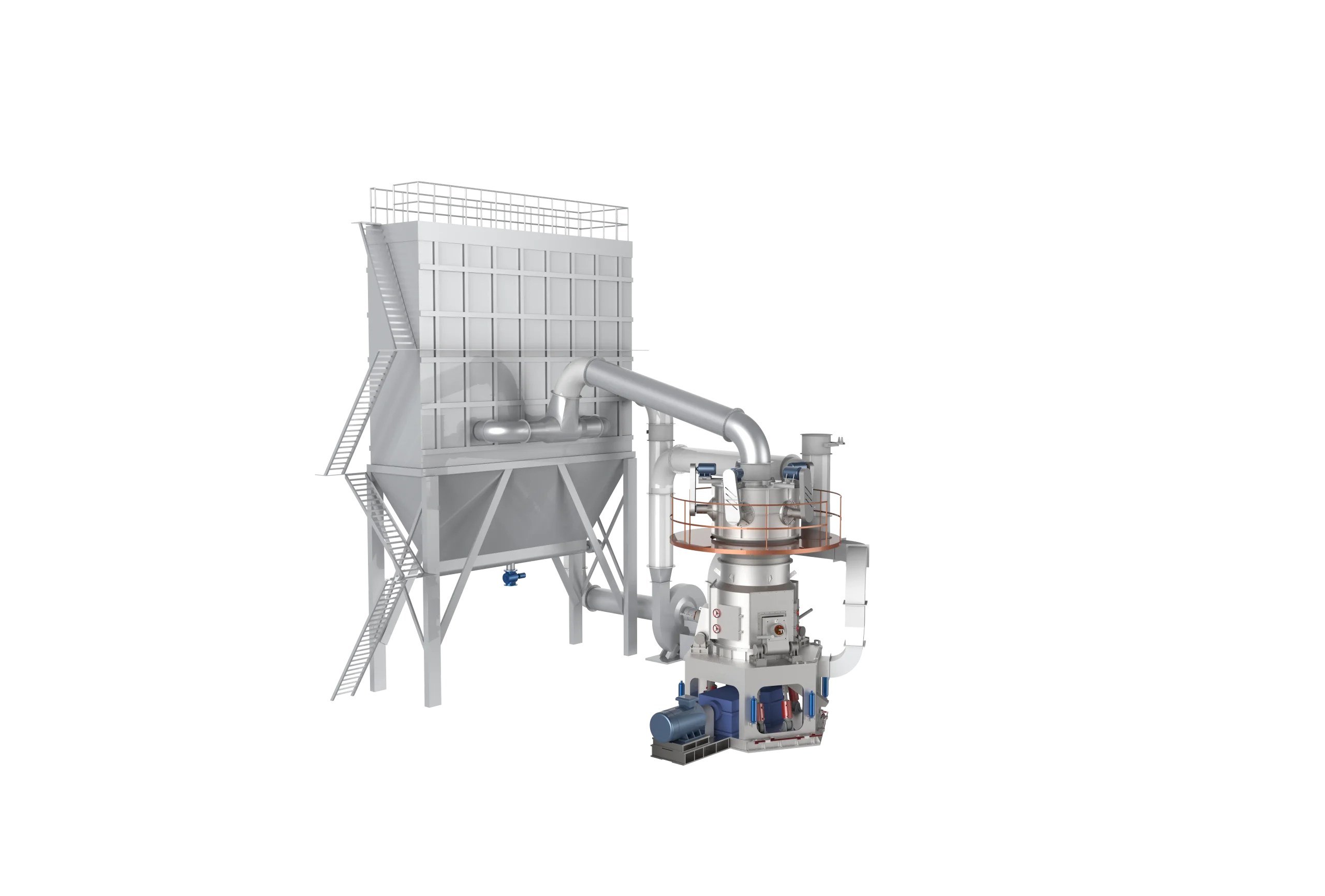

Among the family of grinding equipment, the ultrafine grinding machine, although appearing modestly, is actually quite powerful and is emerging as a prominent player in various industrial fields. It has a vertical structure and achieves fine processing of materials through crushing and grinding. Its core components are ingeniously matched. The rotating grinding ring acts as […]

Natural dihydrate gypsum (CaSO4·2H2O) is also known as raw gypsum. After calcination and grinding, β -type hemihydrate gypsum (CaSO4·1/2H2O) can be obtained, which is building gypsum and is also called calcined gypsum or plaster. If the calcination temperature is 190°C, model gypsum can be obtained, and its fineness and whiteness are both higher than those […]

Advantages of Raymond mill in processing carbon black Output advantage The Raymond mill features an advanced structure and highly efficient principle. It can operate continuously and stably. When processing medium-fineness (80 to 800 mesh) carbon black, it has a high output and can meet the demands of large-scale production. Cost advantage The mechanical structure is […]

Rare earth materials, with their unique physical and chemical properties, play an irreplaceable role in numerous fields. Among them, neodymium iron boron, as a leading rare earth permanent magnetic material, is hailed as the “Magnetic King”. Its outstanding magnetic properties make it one of the core materials in modern industry and electronic technology. This article […]