Among the family of grinding equipment, the ultrafine grinding machine, although appearing modestly, is actually quite powerful and is emerging as a prominent player in various industrial fields. It has a vertical structure and achieves fine processing of materials through crushing and grinding.

Its core components are ingeniously matched. The rotating grinding ring acts as a calm guardian, while the multiple freely swinging grinding rollers inside resemble well-trained dancers. 2 to 4 of them work together to generate powerful crushing force. The material enters from the upper feed port and is crushed, sheared, and ground between the grinding ring and the grinding rollers, completing the transformation from large pieces to fine powder. The fine powder after crushing is carried by the airflow to the upper classifier for separation. The qualified ones are collected, while the “unqualified” ones fall back for re-grinding.

The ultrafine grinding machine has obvious advantages. It has a small footprint and is suitable for factories with limited space. It has low energy consumption and saves electricity costs. It has low noise and improves the working environment. The fineness adjustment range is wide, meeting various demands. It occupies a position in the grinding powder industry and makes people highly expectant of its processing of zeolite.

Zeolite: The Neglected Treasure Mineral

Zeolite is a treasure of nature that has long been overlooked but actually has unique properties and wide applications.

It is a natural or synthetic microporous crystalline aluminosilicate mineral, with a crystal structure resembling a meticulously carved labyrinth. It is composed of three-dimensional silicon (aluminum) oxygen frameworks, filled with regular channels and cavities, giving it unique physical and chemical properties. Physically, it has a Mohs hardness of 3.5 – 5.5, is usually colorless, sometimes appearing in light colors such as flesh red, and has a density of 1.92 – 2.80 g/cm³.

In terms of chemical properties, it has strong ion exchange capacity. The Si⁴⁺ ions in the lattice are replaced by Al³⁺ ions, generating excess negative charges. Alkali metals or alkaline earth metal ions come to balance, enabling it to exchange with other cations in the aqueous solution and exhibit selectivity. It is often used for softening hard water. Its adsorption separation performance is also excellent. The pore structure endows it with a huge internal specific surface area. After dehydration, its adsorption capacity becomes stronger, and it can selectively adsorb molecules like a “molecular filter,” playing a key role in gas separation, wastewater treatment, and other fields. In addition, it has good catalytic properties, chemical stability, reversible dehydration, and certain electrical conductivity. In the petrochemical industry, it is the “star catalyst”; in the building materials industry, it is a cement admixture and lightweight aggregate; in agriculture, it is a soil conditioner, etc. To fully utilize its characteristics, fine processing is indispensable. An ultrafine grinding machine is a good choice for processing it.

Ultrafine Grinding Machine – Why Is It the Perfect Partner for Zeolite?

The Working Principle Unveiled

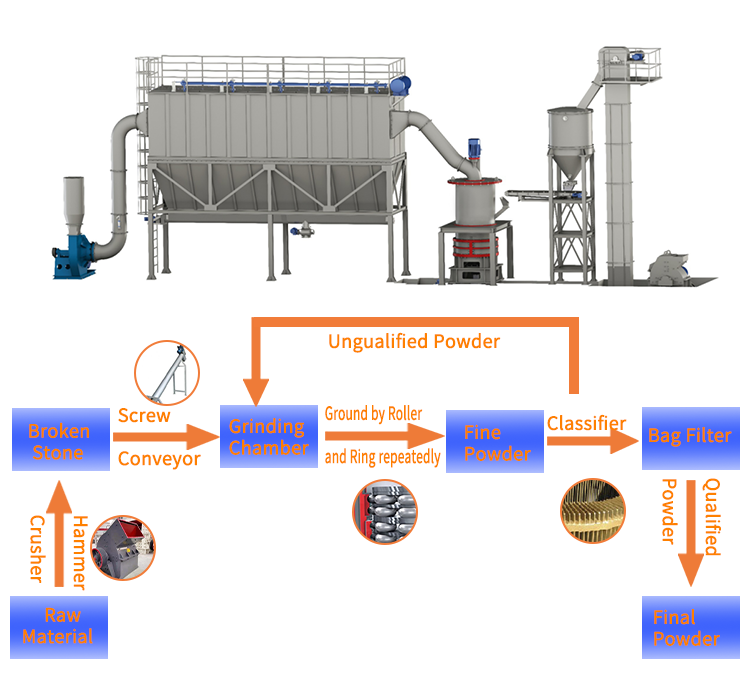

After the materials enter through the feed port, the grinding ring rotates stably. The grinding rollers adhere to the inner wall of the grinding ring under the action of centrifugal force and their own gravity, rotating independently while also moving along with the main shaft in a circular motion. The materials are crushed in the gap between the grinding rollers and the grinding ring by the crushing, shearing, and grinding forces. The crushing is the main method, like the rolling of rollers squeezing the materials; the shearing force is like the cutting of scissors; the grinding force is like the polishing of sandpaper. The fine powder after crushing is pushed by the airflow into the classifier. The classifier adjusts the rotational speed of the classification wheel to screen out the fine powder, and the qualified ones enter the collection system, while the unqualified ones fall back for re-grinding. This cycle repeats until the materials reach the required fineness.

Perfectly Adapted to the Characteristics of Zeolite

The working principle of the ultrafine grinding machine is perfectly compatible with the characteristics of zeolite. From the perspective of protecting the crystal structure, it mainly involves crushing and grinding, which is gentler than high-speed impact type pulverizers. It can avoid damaging the internal microporous structure of zeolite and retain its adsorption and catalytic properties. In terms of controlling the particle size distribution, it can flexibly adjust the particle size by adjusting the rotational speed of the classifier, meeting the requirements of different application scenarios for the particle size of zeolite. In terms of reducing impurity pollution, the main worn parts in the grinding area, such as the grinding rollers and grinding rings, can be made of high-maintenance alloy or ceramic materials, which are wear-resistant and do not produce impurities, ensuring the high purity and whiteness of the zeolite products.

The Entire Processing Process Is Fully Disclosed, with Plenty of Details!

When processing zeolite using a superfine grinding machine, the pre-treatment of raw materials in the early stage is crucial. During the drying process, the moisture content of the raw materials before entering the grinding machine should be controlled below 2%. Excessive moisture will reduce the grinding efficiency, cause blockage, and interfere with the operation of the classifier. Usually, a rotary dryer is used for drying. In the screening stage, impurities such as iron blocks mixed in the zeolite raw materials will damage the equipment. They need to be cleaned using a magnetic separator. In the primary crushing stage, natural zeolite is a large block of ore, and it needs to be crushed into small pieces less than 20mm using a jaw crusher to prepare for the subsequent grinding process.

While Grinding the Powder

The pre-treated zeolite raw materials enter the ultrafine grinding mill. The grinding ring rotates, while the grinding rollers adhere to the inner wall and rotate both independently and collectively. The materials are crushed into fine powder under the pressure, shear force, and grinding force in the gaps between them. The fine powder is pushed by the airflow and enters the classifier. The classifier adjusts the rotational speed of the classification wheels to screen out the fine powder, and the qualified ones enter the collection system, while the unqualified ones fall back for re-grinding. The process is efficient and orderly.

Post-processing to Maintain Quality

In the product collection stage, the efficient pulse bag dust collector captures fine powder under the action of the negative pressure circulation system. The pulse cleaning device performs regular cleaning to achieve efficient collection of fine powder. For applications with high purity requirements, a strong magnetic drum separator is used at the product outlet to remove residual ferromagnetic impurities. In special applications, the zeolite powder can be subjected to surface modification or size classification treatment. Surface modification can change its surface properties and expand its application range; size classification can meet the special particle size requirements of different customers.

Real Application Cases Speak for Themselves!

Agricultural Sector: Facilitating Soil Improvement and Enhancing Crop Yields

At a large agricultural planting base, the soil became compacted and its fertility declined. Using an ultrafine grinding machine, the zeolite was processed into fine powder with a size of 200 – 300 microns as a soil conditioner. After the improvement, the soil’s agglomerate structure was enhanced, its water retention and fertilizer retention capabilities were improved, and it could also adsorb heavy metal pollutants. The growth conditions of crops significantly improved. Taking wheat as an example, the yield increased by about 20%, and the quality of agricultural products improved.

Environmental Protection Field: Efficiently Treat Sewage, Guarding Clear Water and Blue Skies

The wastewater treatment facility of a certain plant failed to achieve satisfactory results in treating wastewater containing heavy metal ions and organic pollutants. To address this issue, the plant used an ultrafine grinding machine to process zeolite into fine powder with a size of 400 – 500 mesh to treat the wastewater. The zeolite powder can quickly capture heavy metal ions and organic pollutants, and the treated wastewater meets the discharge standards, achieving water resource recycling. Moreover, using zeolite powder is cost-effective and simple to operate, reducing the cost of treating each ton of wastewater by approximately 30%.

Industrial Sector: As a Catalyst Carrier, Enhancing Production Efficiency

A petrochemical plant needed high-performance catalyst carriers to enhance the efficiency of catalytic cracking reactions. They used an ultrafine grinding machine to process zeolite into 800 – 1000 mesh ultrafine powder as the carriers. The zeolite powder has good dispersibility and stability, which can better load the active components of the catalyst and improve the catalyst’s activity and selectivity. After its use, the efficiency of catalytic cracking reactions significantly increased, with the production efficiency rising by about 35%, and the product quality improved.

There Are Tricks to Choosing and Maintaining.

When choosing an appropriate ultrafine grinding machine, the model should be selected based on the target output and fineness. For large-scale production with high output requirements, a machine with greater production capacity should be chosen. For products with strict fineness requirements, a machine capable of achieving finer particle sizes should be selected. Pay attention to the material of the key contact components. For processing zeolite, it is recommended to use high-chromium alloy or ceramic-lined grinding rollers and grinding rings. Also, consider factors such as equipment energy consumption, floor space, and price comprehensively, and choose the one with better cost performance.

Maintenance Guide

To maintain the ultrafine grinding machine, it is necessary to conduct regular inspections of the equipment. Before starting the machine, check the tightness of each component, the tightness of the transmission parts, the lubrication system, the feeding system, etc. During operation, monitor the motor current and bearing temperature, and pay attention to abnormal noises and vibrations. Every 500 hours or so, check the wear condition of the grinding rolls and grinding rings and replace them in time. Also, regularly inspect and replace the impeller, liner plates, etc. of the machine. Choose reliable quality parts. Regularly clean the equipment, including the body and each component, using appropriate tools and cleaning agents, and keep the working environment clean. Establish a maintenance ledger to record the maintenance time, content, replacement of parts, etc.