Contents Catalog

Impact crusher, renowned for their high efficiency and versatility, play a crucial role in various industries. Their application areas and suitable materials are as follows:

Application Areas of Impact Crusher

Mining Industry

In the mining sector, impact crushers are indispensable for the primary and secondary crushing of ore. They are used in open – pit and underground mines to process extracted minerals, reducing large – sized ore blocks into smaller pieces suitable for subsequent processing steps such as grinding and beneficiation. This not only improves the efficiency of mineral extraction but also helps in optimizing the use of resources.

Construction and Building Materials Industry

For the construction industry, impact crushers are widely used in the production of aggregates. High-quality aggregates are essential for concrete, asphalt, and road base materials. These crushers can produce aggregates with excellent grain shape and particle size distribution, which are highly suitable for building construction, road construction, and bridge building projects. Additionally, in the production of building materials like bricks and tiles, impact crushers are used to crush raw materials such as clay and shale to the required fineness.

Recycling Industry

With the increasing focus on environmental protection, impact crushers have found significant application in the recycling industry. They are used to process waste construction materials, such as concrete debris, bricks, and stones. By crushing these waste materials, reusable aggregates can be obtained, which can be used in new construction projects, reducing the demand for virgin materials and minimizing waste disposal problems. Moreover, impact crushers can also be applied to recycle waste metals by crushing them into smaller pieces for further separation and processing.

Chemical Industry

In the chemical industry, impact crushers are utilized for crushing raw materials used in the production of various chemicals. For example, they can be used to crush minerals and ores that serve as raw materials for chemical synthesis, ensuring a uniform particle size for more efficient chemical reactions.

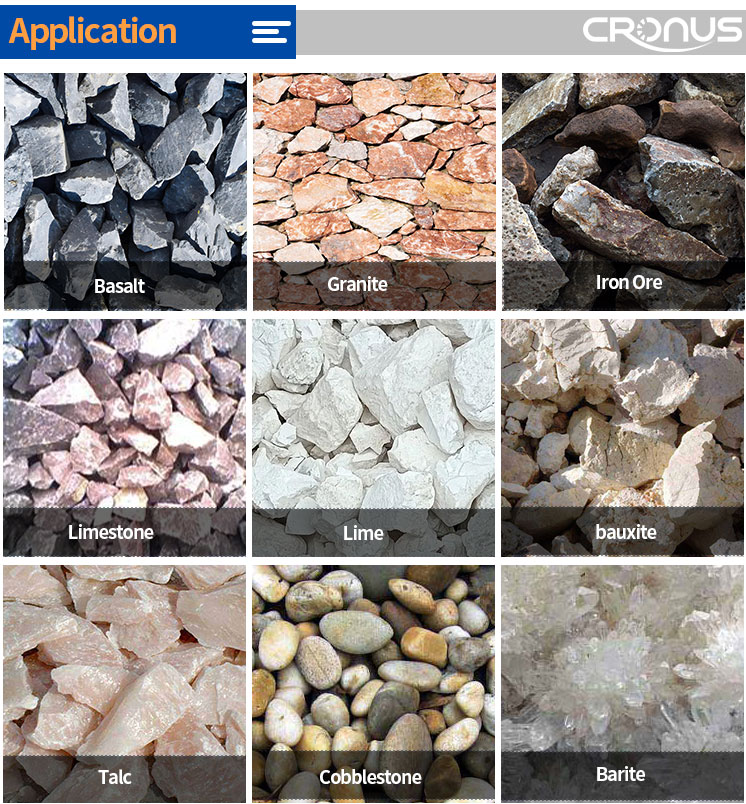

Impact Crusher Applicable Materials

Hard and Medium-Hard Materials

Impact crushers are highly effective in handling hard and medium-hard materials. This includes various types of rocks such as limestone, granite, basalt, and quartzite. Limestone, a common raw material in the cement industry, can be efficiently crushed by impact crushers to meet the size requirements for cement production. Granite and basalt are widely used in the construction of high-grade roads and buildings, and impact crushers can process them into aggregates with excellent quality.

Soft Materials

They can also handle soft materials like gypsum, coal, and clay. Gypsum, used in the production of plasterboards and other building materials, can be crushed into fine powder by impact crushers. Coal, before being used in power plants or other industrial applications, often needs to be crushed, and impact crushers can perform this task efficiently. Clay, a basic raw material for bricks and tiles, can be processed by impact crushers to achieve the appropriate particle size for shaping.

Waste Materials

As mentioned in the recycling industry, impact crushers are capable of processing a wide range of waste materials. In addition to waste construction materials, they can also handle waste glass, ceramic waste, and some types of plastic waste. By crushing these waste materials, they can be more easily recycled or disposed of in an environmentally friendly manner.

In conclusion, impact crushers’ wide-ranging application areas and diverse applicable materials make them essential equipment in modern industrial production, contributing significantly to resource utilization, construction development, and environmental protection.

Impact Crusher Working Principle

PF Impact Crusher breaks materials with impact force. When working, driven by a motor, the rotor rotates at a high speed. When materials enter the working area of hammer, they are crushed under the high-speed shock. Then broken materials are thrown onto the lining plate for another crushing. Finally, qualified materials are discharged from the opening. Adjusting the gap between the impact rack and rotor rack can change the granularity and shape of finished products.

Impact Crusher Product Parameters

| Model | Rotor Size* length (mm) | Feed Opening Size (mm) | Max. Feeding Size (mm)s | Capacity (t/h) | Motor Power (kw) | Overall Dimension (mm) |

| PF-1007 | Φ1000×700 | 400×730 | 300 | 35-50 | 55 | 2400×1558×2660 |

| PF1010 | Φ1000×1050 | 400×1080 | 350 | 50-80 | 4-75 | 2455×2086×2800 |

| PF1210 | Φ1250×1050 | 400×1080 | 350 | 60-120 | 6-110 | 2590×2050×2800 |

| PF1214 | Φ1250×1400 | 400×1430 | 350 | 80-160 | 6-132 | 2590×2400×2810 |

| PF1315 | Φ1300×1500 | 860×1520 | 350 | 120-260 | 6-200 | 2930×2760×3050 |

| PF-1515 | Φ1500×1500 | 1145×1520 | ≤500 | 220-280 | 280kw | 2690×2049×2698 |

| PF-1520 | Φ1520×2000 | 1245×2050 | 700 | 300-550 | 315-440 | 3581×3560×3865 |

Impact Crusher customer sites